Method for manufacturing semiconductor device and substrate processing apparatus

a technology of substrate processing and semiconductor devices, which is applied in the direction of liquid surface applicators, coatings, chemical vapor deposition coatings, etc., can solve the problems of metallic contamination, reduced film formation speed (film formation rate) sometimes, and foreign substances in the processing chamber. achieve the effect of adequate etching ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

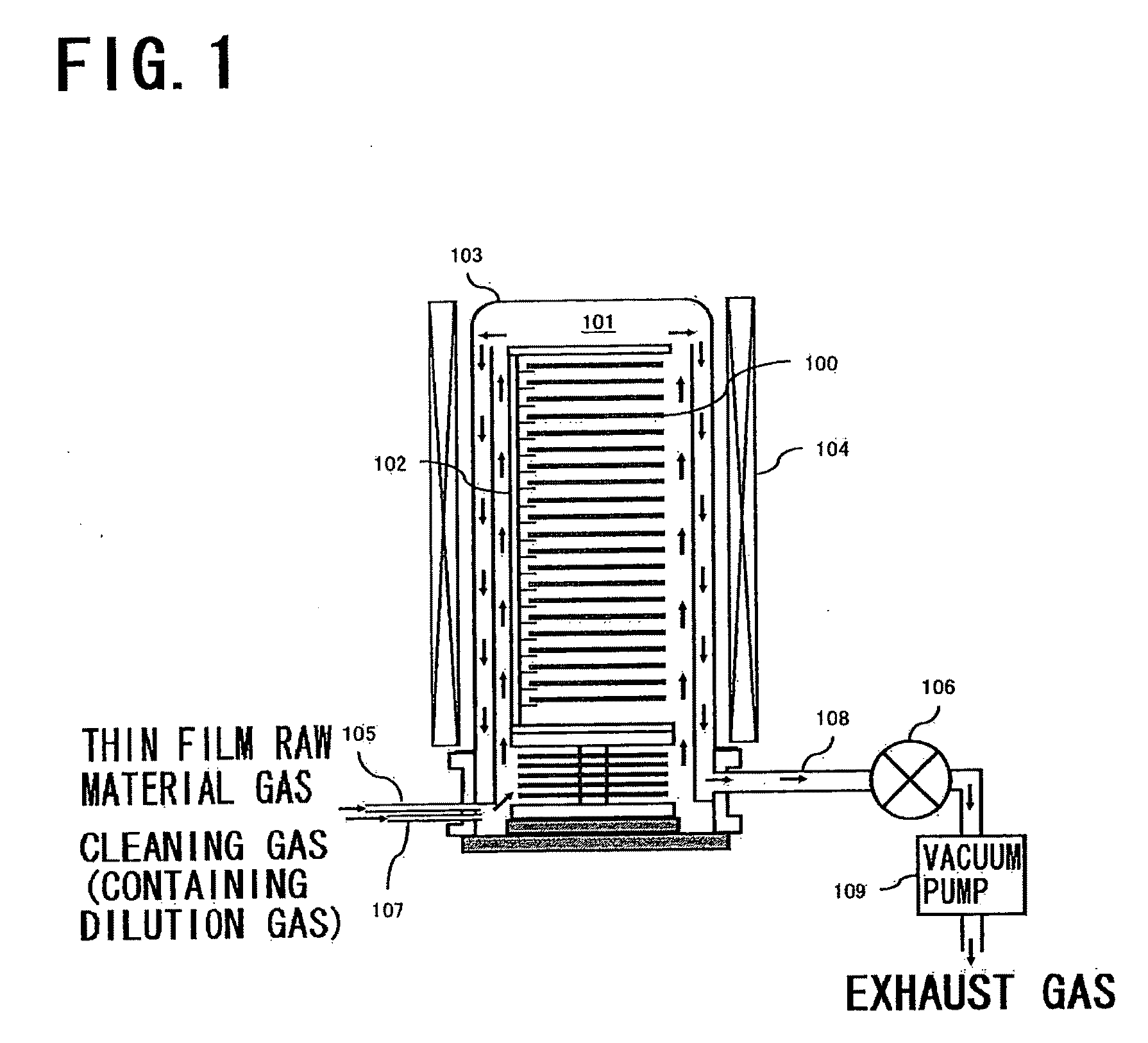

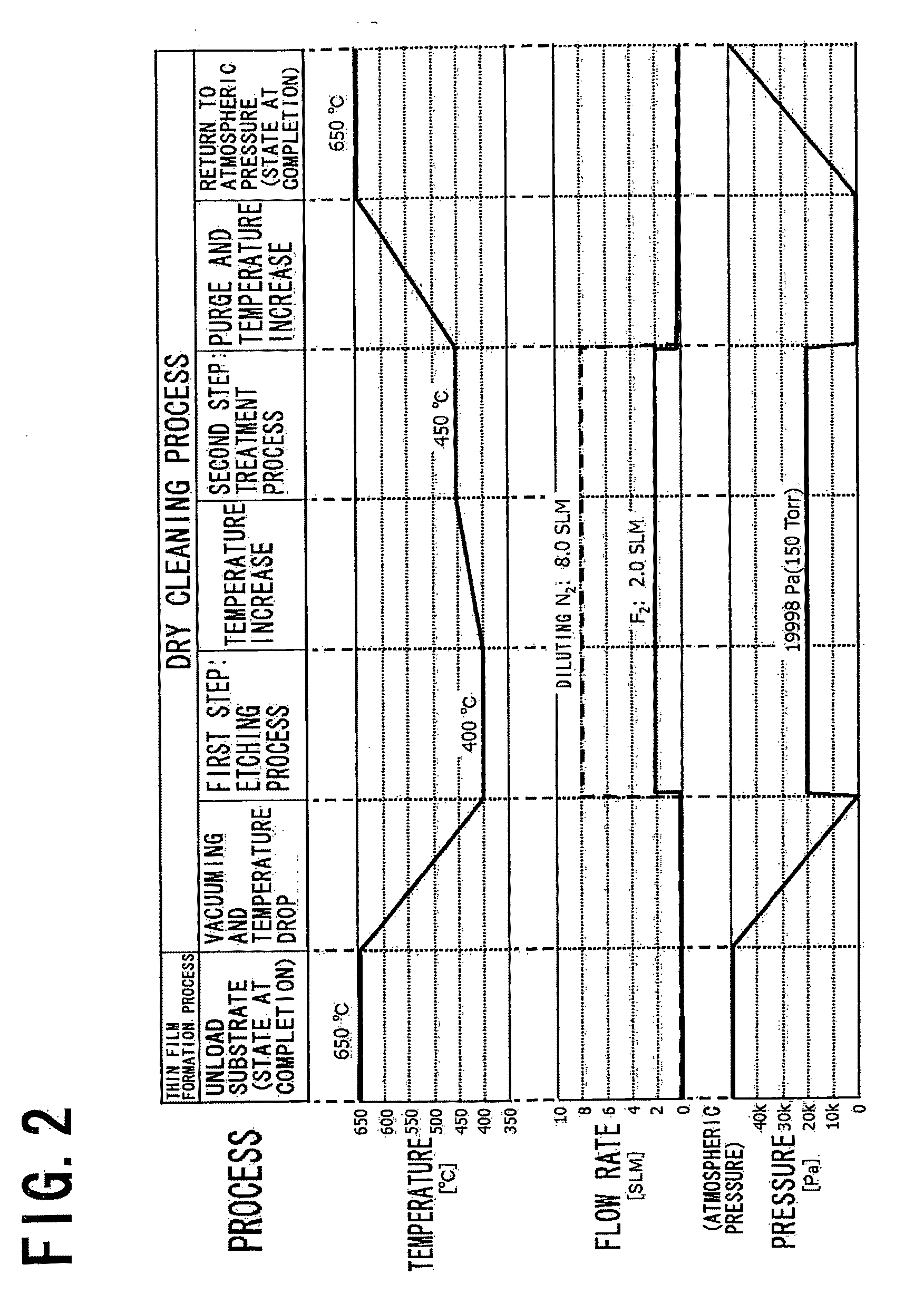

[0119]As Example 1 of the present invention, a case where the cleaning is performed, with the temperature (second temperature) in the processing chamber 201 in the second step (treatment process) being set higher than the temperature (first temperature) in the processing chamber 201 in the first step (thin film etching process) will be described. FIG. 2 is a graph chart showing the sequence and the cleaning conditions of the cleaning step according to the Example 1 of the present invention.

[0120]In the thin film formation process of Example 1, a silicon nitride film was formed with use of SiH2Cl2 (DCS) gas and NH3 gas, as the processing gas, in accordance with the same method and conditions as those in the above-described embodiment. The film thickness of the silicon nitride to be formed by a single thin film formation process was set to 500 Å. After the thin film formation process was performed 16 times (every time when cumulative film thickness becomes 8000 Å), the cleaning proces...

example 2

[0123]As Example 2 of the present invention, a case where the cleaning step was performed, with both the temperature (first temperature) in the processing chamber 201 in the first step (thin film etching process) and the temperature (second temperature) in the processing chamber 201 in the second step (treatment process) being set to 450° C., will be described. FIG. 3 is a graph chart showing the sequence and the cleaning conditions of the cleaning according to the Example 2 of the present invention. Other conditions are the same as those in the Example 1.

[0124]As is the case with the Example 1, the 16 times of the thin film formation processes and the subsequent cleaning step were assumed as 1 cycle. Next, the cycle was repeated a plurality of times. Every time the thin film formation process is completed, the amount of increased foreign substances in the processing chamber 201 was measured, and the film formation rate of silicon nitride film was also measured.

[0125]In both the Exa...

example 3

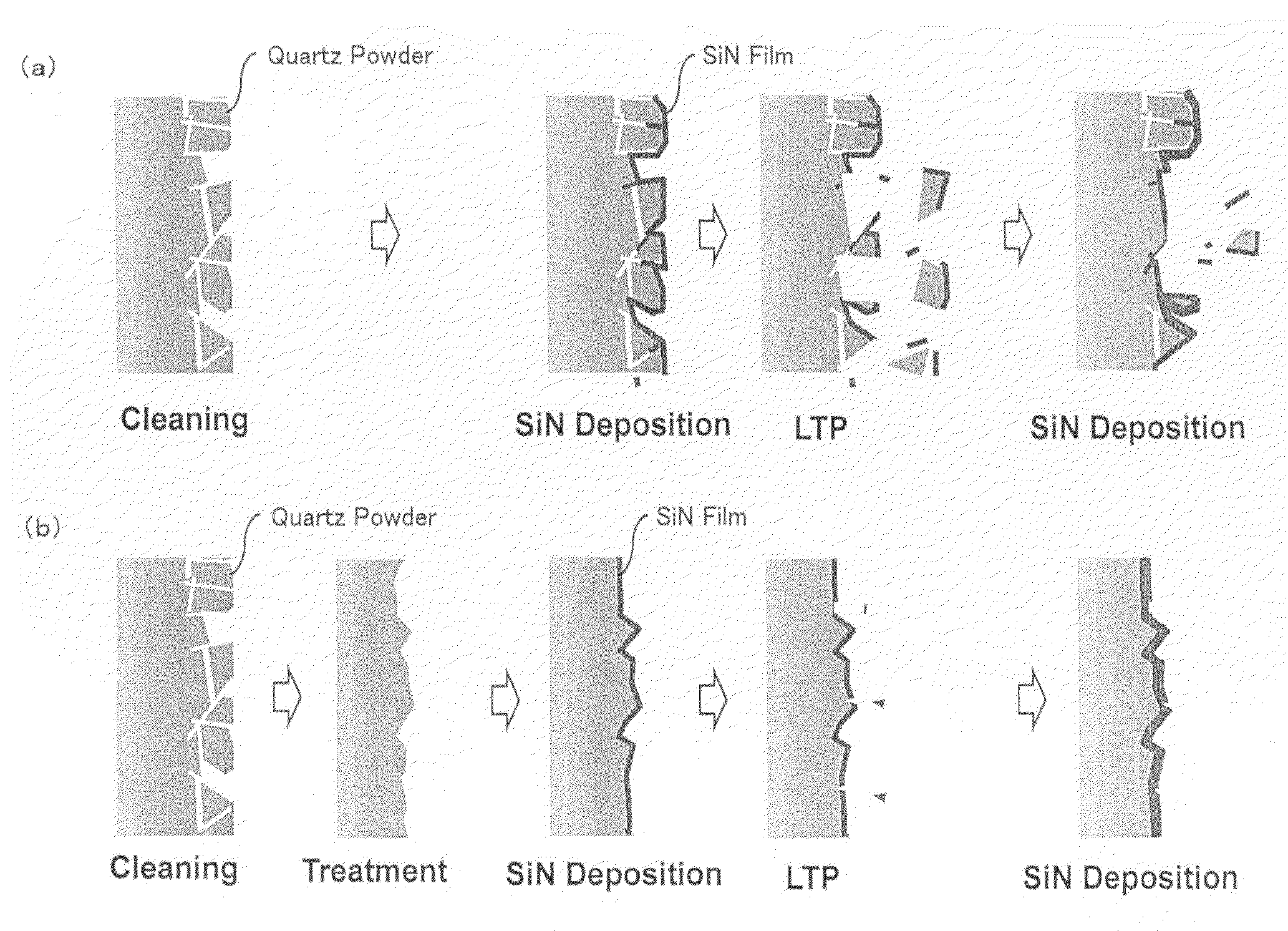

[0130]As Example 3 of the present invention, a case in which the cleaning in the above-described embodiment (Example 1, Example 2) and LTP (Low Temperature Purge) are combined will be described. The LTP, also called as the low temperature purge, herein refers to purge of the inside of the processing chamber 201 with gas, while applying a thermal impact onto the thin film deposited on the inside of the processing chamber 201 by decreasing a temperature in the processing chamber 201, so as to forcibly generate a crack in the thin film and forcibly peel the adhered material adhered on the inside of the processing chamber with a weak adhesive force.

[0131]In the meantime, the above-described embodiment (Example 1, Example 2) is an art based on the assumption that a substrate processing apparatus which performs the dry cleaning process is operated. However, when a practical operation of the apparatus is considered, the thin films accumulated on the inside of the processing chamber 201 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com