Posts For Road Safety Barrier

a technology for road safety and posts, applied in fencing, ways, buildings, etc., can solve the problems of little connectivity/cohesion with posts, vehicle straddling, overturning of vehicles, etc., and achieve the effect of reducing the risk of post collapse or damage, and enhancing the containment/retardation capacity of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

worked example

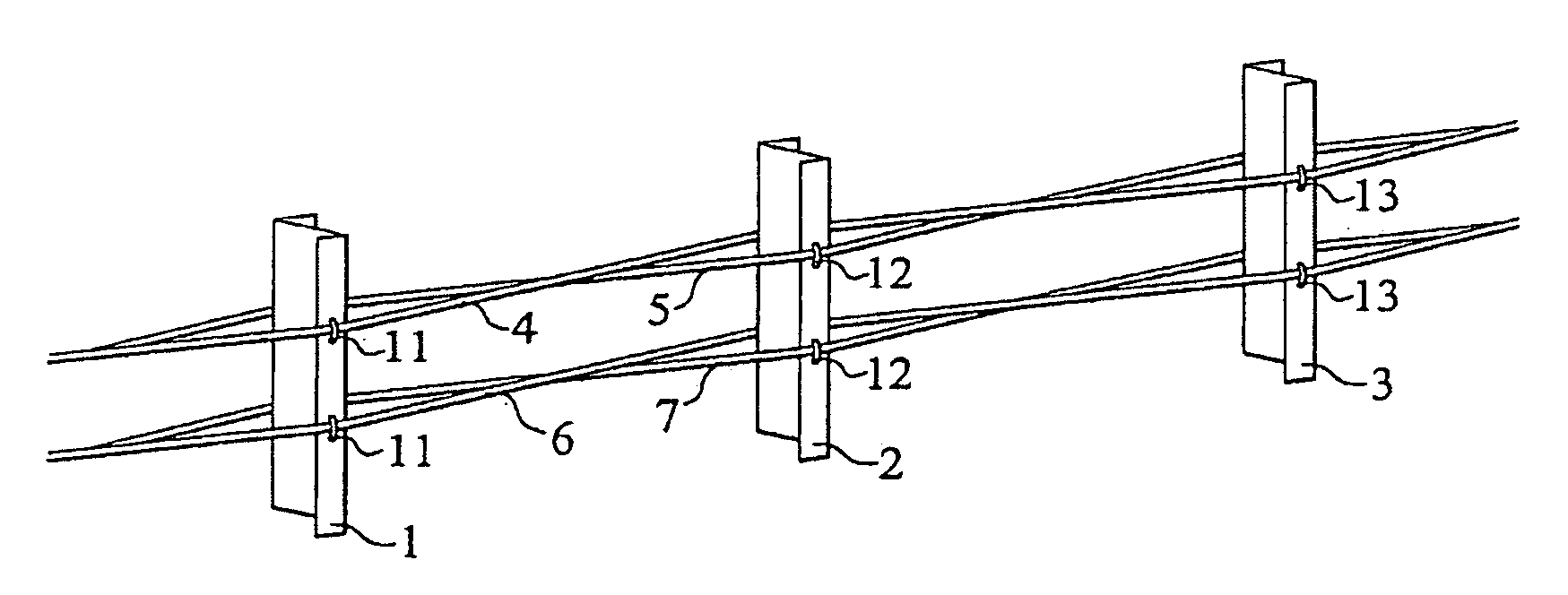

[0044]Consider the case of a 4-rope interwoven barrier in which the ropes have a mean heist above ground level of 550 mm and posts at 2.4 m spacing, each having a depth of 100 mm. The resulting angular deviation of the ropes (in plan view relative to the line of the barrier) will be 2.38 degrees. If we assume for design purposes that each rope will see a tension of 50 kN, then it can be shown that the four ropes will generate a frictional grip on a post of 3.33 kN (taking the coefficient of friction to be 0.20). The effect of this force is to create a bending moment in the post which will reach a maximum of 1832 Nm (at the base of the post) before the ropes slip. The result of this bending moment in terms of maximum bending stress will vary with the strength and stiffness of the type of post selected as illustrated in the table below:

[0045]Comparison of Maximum Bending Stresses in Z-Posts at 2.4 m Centres:

In-lineCombinedPost dimensions mmmoment ofbendingMaximum bendingD × W × Thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com