Plasma display panel and method for manufacturing the same

a technology of plasma and display panel, which is applied in the manufacture of electrode systems, electric discharge tubes/lamps, electrodes, etc., can solve the problems of a small chance of discharge completion, a time lag, and a generation evidently occurring, so as to reduce the surface free energy and reduce the chance of discharge completion. , the effect of large secondary electron emission coefficient and smooth emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Structure of PDP

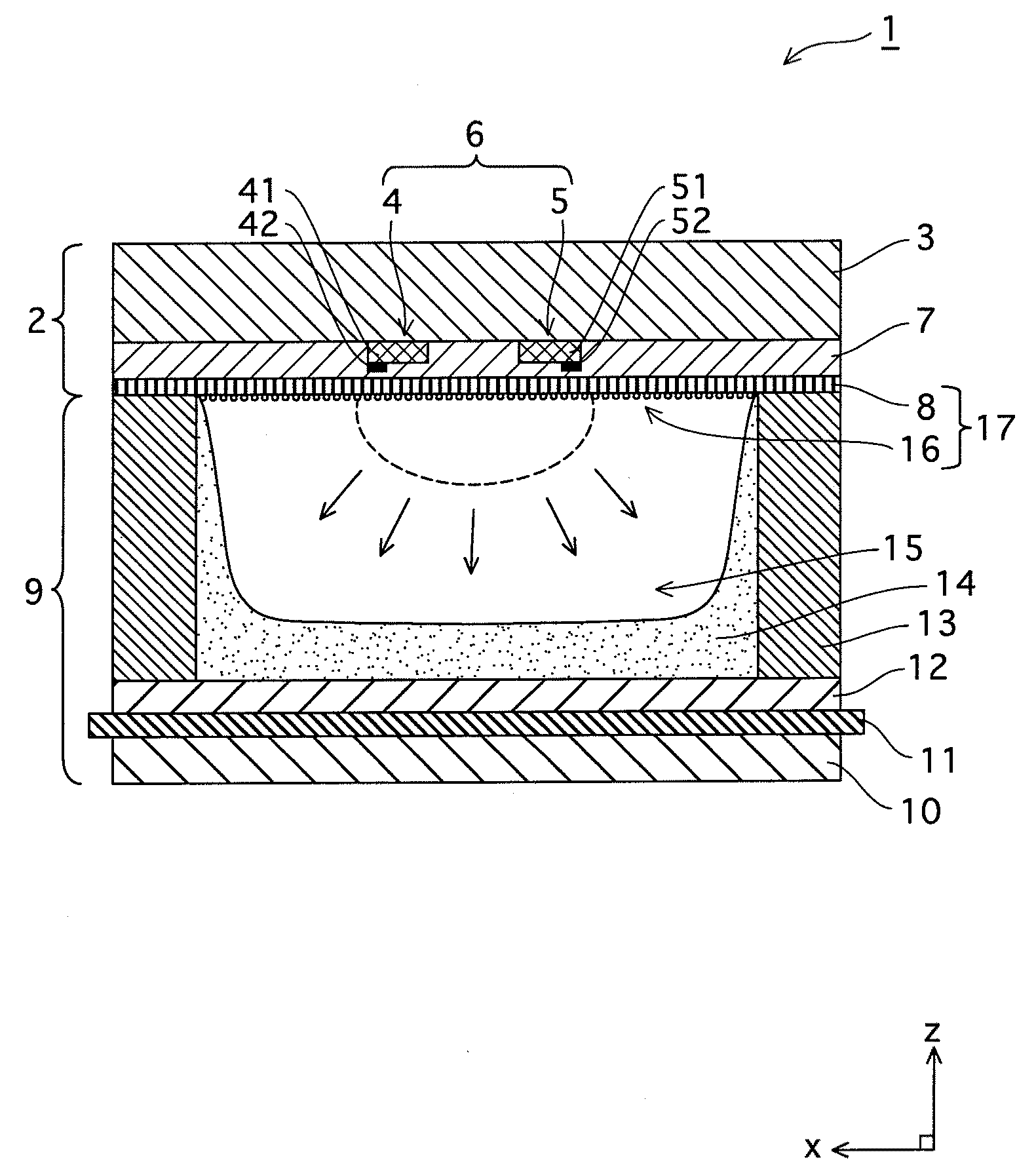

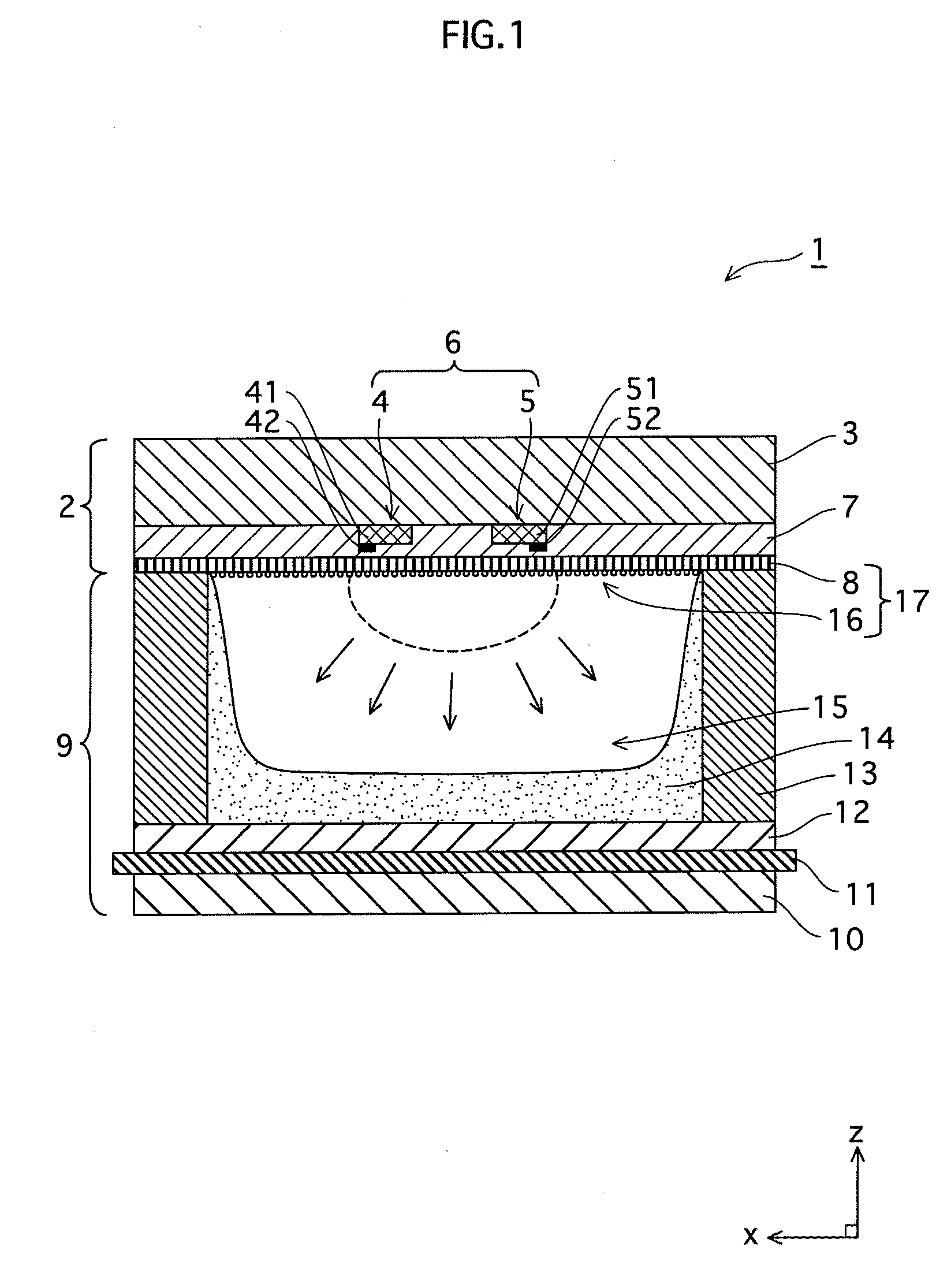

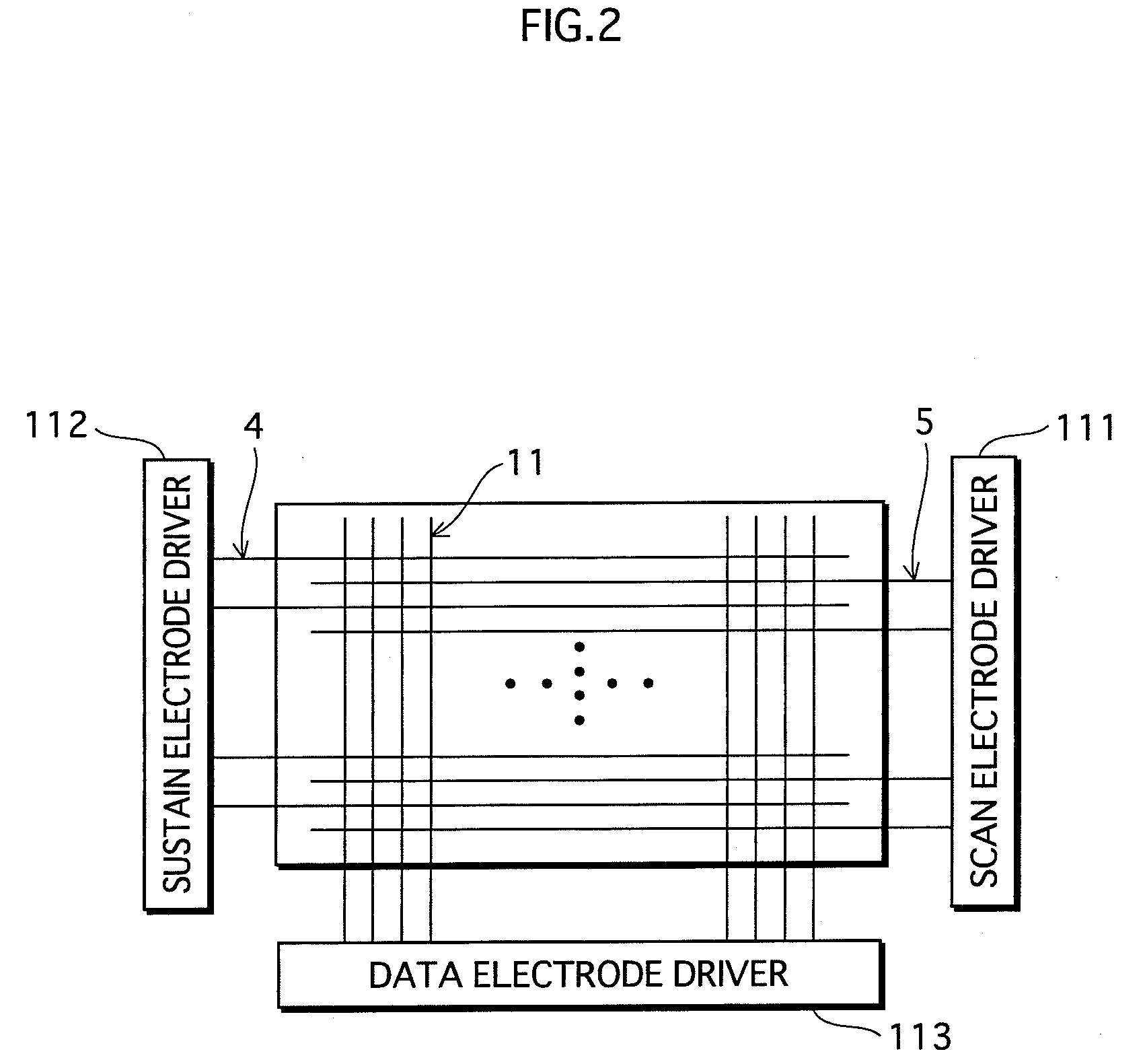

[0063]FIG. 1 is a schematic sectional view of a PDP 1 in accordance with Embodiment 1 of the present invention, the section being taken along the x-z plane. The structure of the PDP 1 is basically identical with that of a conventional PDP (FIG. 10) except for the structure in the vicinity of the protective layer.

[0064]The PDP 1 is an AC PDP with a 42-inch screen in conformity with the NTSC specification. The present invention may be, of course, applied to other specifications such as XGA and SXGA. The applicable specifications of the high-definition PDP that is able to display images at a higher resolution than an HD (high-definition) PDP are PDPs with a size of 37, 42, and 50 inches having 24×720 (pixels), 1024×768 (pixels), and 1366×768 (pixels), respectively. In addition, such a PDP is also applicable to display images at higher resolution than the PDP 1. Examples of a PDP having higher-definition pixels than the HD PDP include a full HD PDP with 1920×1080 (pixels...

embodiment 2

[0128]Following is a description of a PDP 1a in accordance with Embodiment 2 of the present invention. The differences between the PDP 1 and the PDP 1a are mainly described. FIG. 7 is a cross-sectional view of the PDP 1a. FIG. 4B is a schematic view showing the protective layer of the PDP 1a and its nearby portion.

[0129]The feature of the PDP 1a is that the protective layer is composed of the MgO powder 16 disposed directly on the dielectric layer 7 does not include the surface layer 8. The MgO powder 16 includes the MgO particles 16a-16d as with Embodiment 1.

[0130]The PDP 1a with the above feature promotes the smooth secondary electron emission in the wide temperature range from low to a normal temperature or higher when the PDP 1a is initially driven. Thus, the PDP 1a can display excellent images by effectively suppressing the “discharge delay” and “dependence of discharge delay on temperatures.” In addition, the MgO particle 16c included in the MgO powder 16 can improve the depen...

experiment 1

Evaluation of MgO Particle's Crystal Face

[0188]With use of Samples 1, 4, 5, 7-9, a ratio of a surface area of the (100) crystal face to a surface area of the (111) crystal face of each MgO particle of the protective layer was measured. Although the area ratio can be actually measured by visual observation with an electron microscope, the crystal faces are comprehensively identified by an analysis with electron beams and the like in this experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com