Recovery process for precious metals

a recovery process and precious metal technology, applied in the field of recovery process for precious metals, can solve the problems of high consumption of leaching solution and general toxicity, and achieve the effect of reducing capital and operating costs and reducing retention times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Laboratory Processing of a Gold Ore Sample

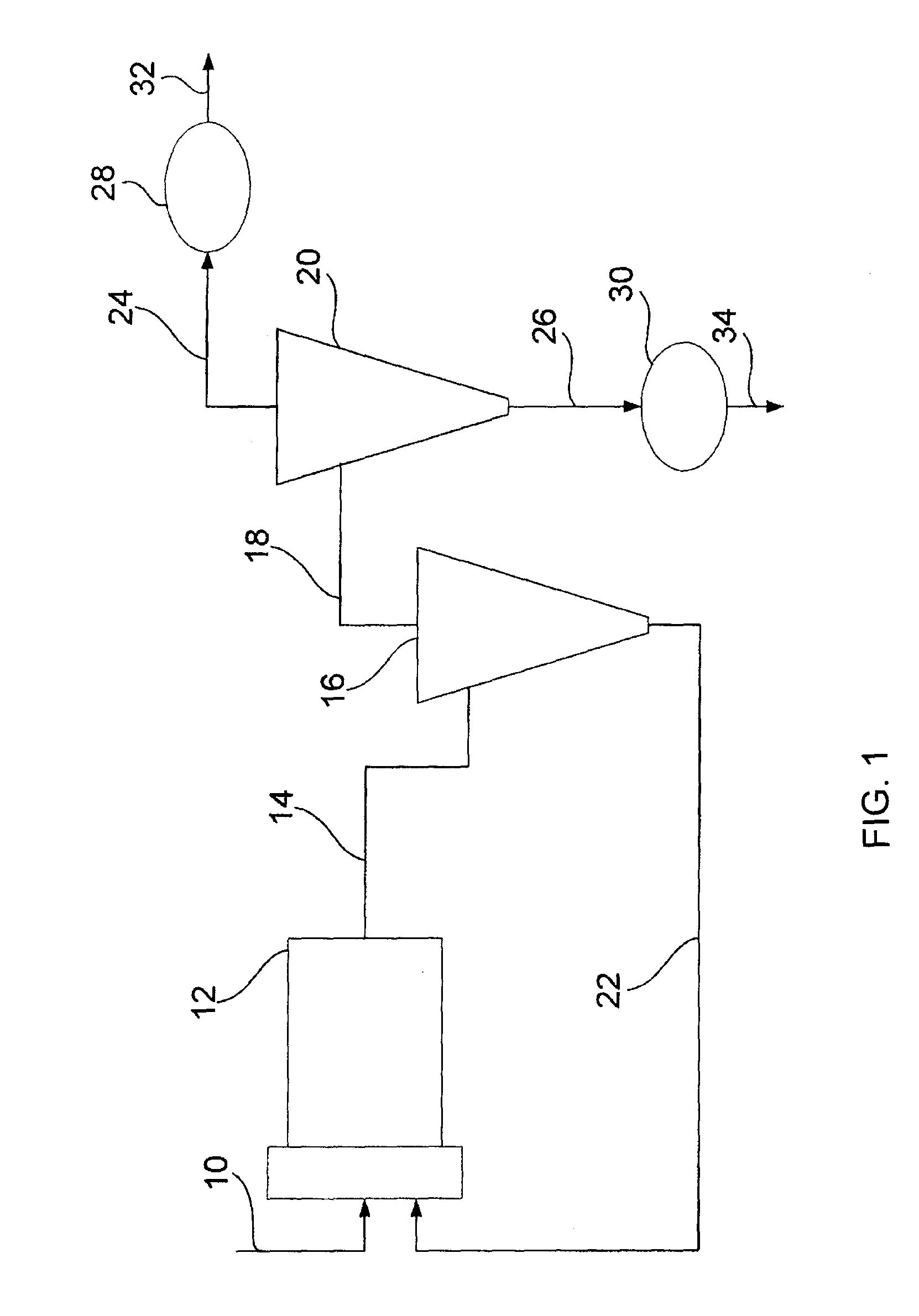

[0039]A gold bearing ore from the Iamgold, Sleeping Giant Mine division was provided. The ore was processed as per the flowsheet presented in FIG. 1 in laboratory size equipment. The ore was comminuted in a closed loop grinding step with an addition of cyanide in the laboratory size equipment. The ore particles were separated by screening into two particle size classes: a fine particle class and a coarse particle class. The fine particle class have a d80 smaller than 38 μm, and preferably less than 25 μm. The coarse particles were characterized by a d80 larger than 38 μm but smaller than 150 μm, preferably smaller than 100 μm and most preferably smaller than 80 μm. 40 wt % of the ore was contained in the coarse particle class and the remaining 60 wt % of the ore was contained in the fine particle class. The coarse particle class had a mean gold grade of 2 gram per tonne while the fine particle class had a mean gold grade of 7 gram per tonne....

example 2

Industrially Comminuted Ore Sample with Laboratory Scale Gold Recovery

[0049]An gold bearing ore sample from the Iamgold, Sleeping Giant Mine division was obtained from the full sized comminution circuit of the operating gold plant. The industrially comminuted ore sample was processed in laboratory size equipment using a flowsheet as per FIG. 1. For greater clarity the ore sample collected and used as the feed stream for cyanidation, is equivalent to feed stream 18 (stream and equipment reference numbers are as per FIG. 1). The process steps of unit operation 12 and 16 in FIG. 1 were conducted at an Industrial scale. As in Example 1, the industrially comminuted ore of Example 2 was comminuted with an addition of cyanide.

[0050]In Example 2 the industrially comminuted ore particles from feed stream 18 were classified using a 1¼″ hydrocyclone 20. The cut size (d50c) from the hydrocyclone 20, was 28 μm, as can be determined from FIG. 5 and indicated as the a mass ratio of underflow 26 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com