Compositions and processes for deposition of metal ions onto surfaces of conductive substrates

a technology of conductive substrates and compositions, applied in the direction of liquid/solution decomposition chemical coating, solid/suspension decomposition chemical coating, coating, etc., can solve the problems of insufficient tenacity of deposits to maintain integrity, environmental hazards and public health hazards, and cyanide, which is an extremely toxic material, and achieves the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]While the following description details the preferred embodiments of the present invention, it is to be understood that the invention is not limited in its application to the details of construction and arrangement of the parts illustrated in the accompanying drawings, since the invention is capable of other embodiments and of being practiced in various ways.

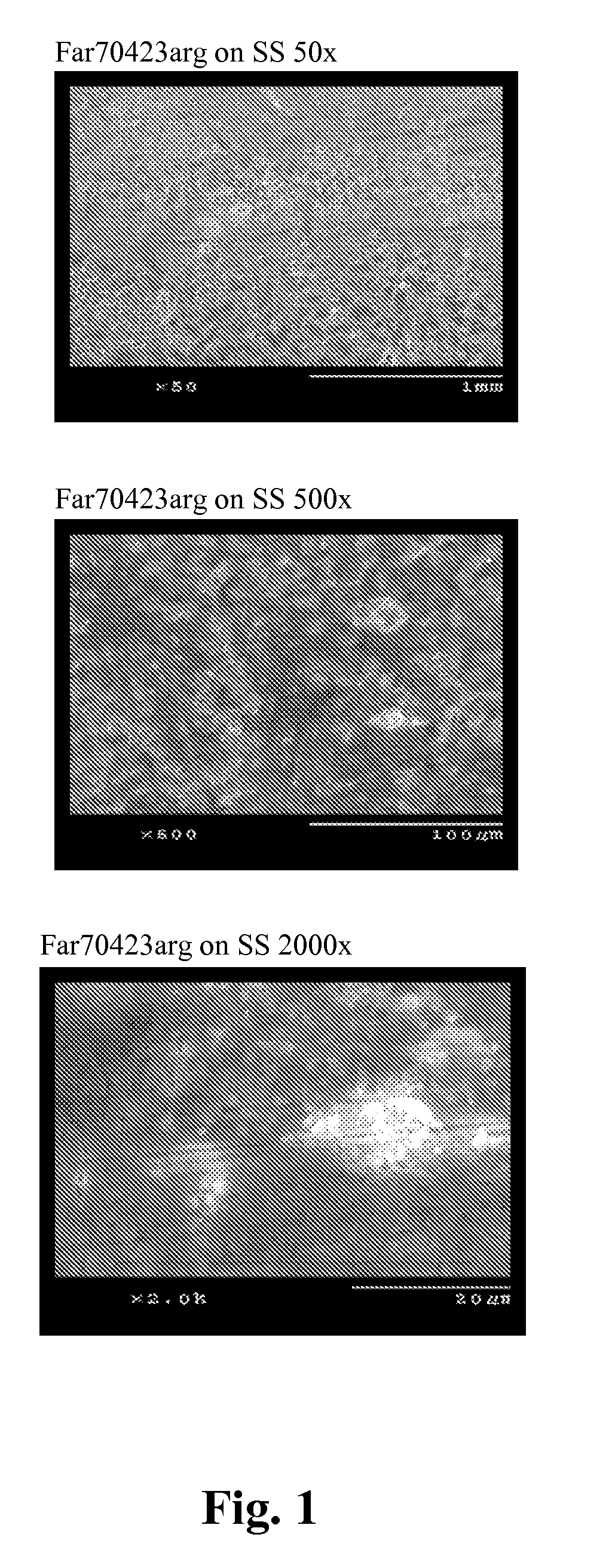

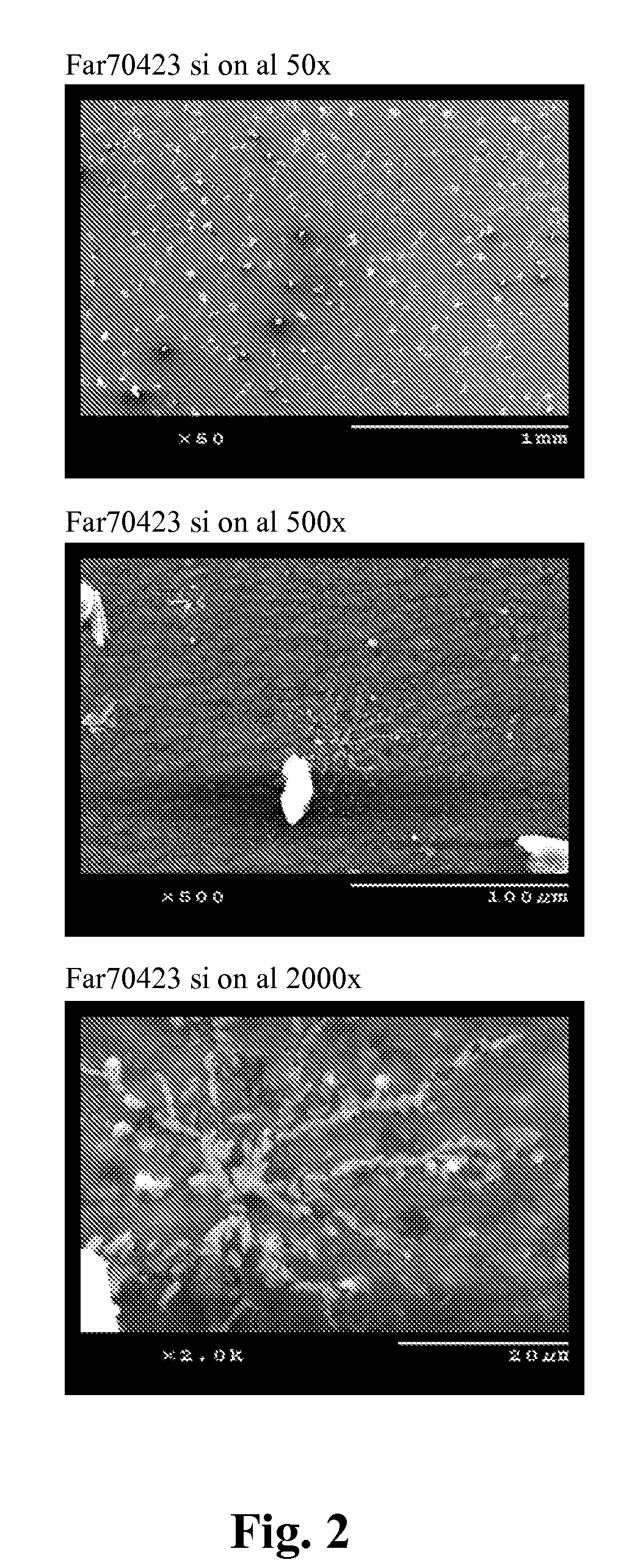

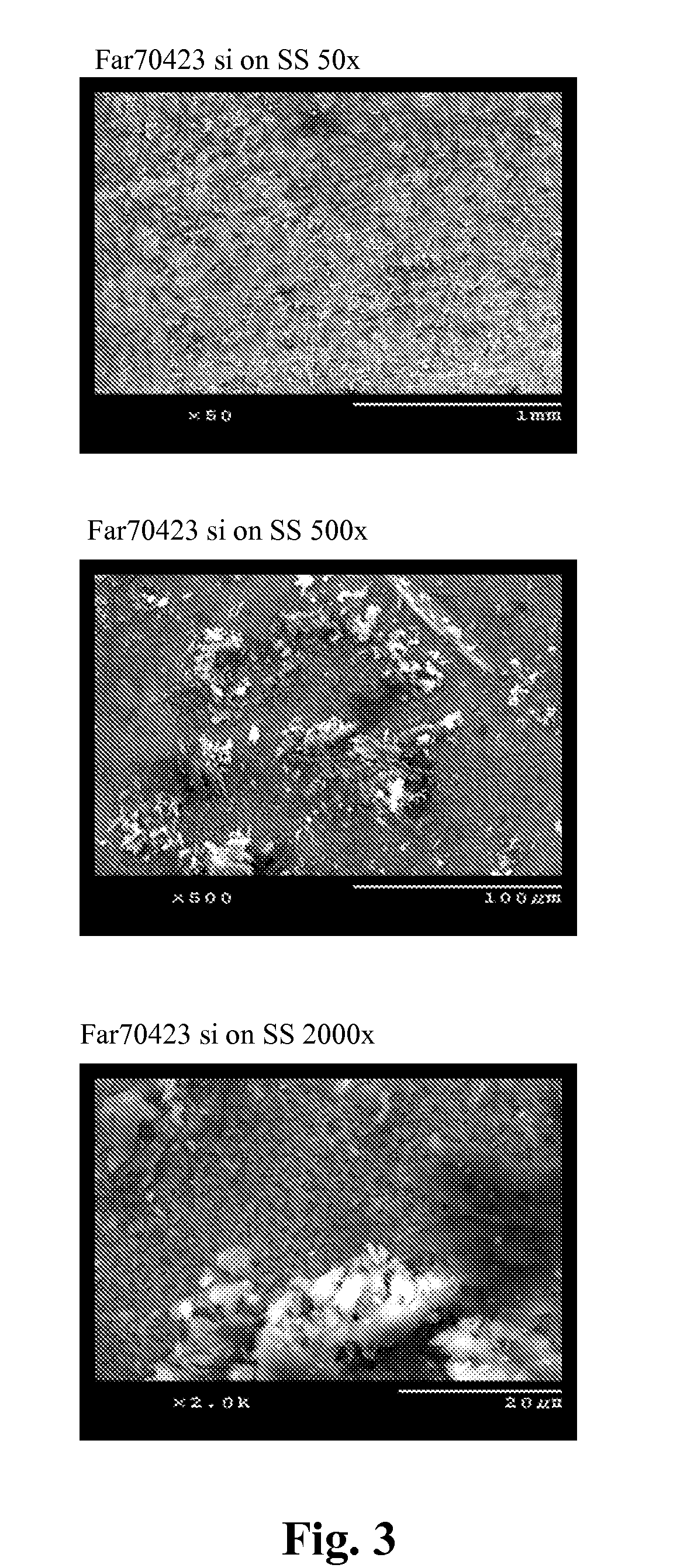

[0042]There is a need for an inexpensive, efficacious, easy to apply technique to reduce metal to metal friction at the atomic level. Surprisingly, when metal ions are produced according to the present invention, the ions so produced diffuase into metal interstices. Surprisingly, the ions produced do not follow the rules of the Electromotive Series, i.e. aluminum can be deposited on ferrous metals, which is not anticipated in any previous literature. Surprisingly, silver ions generated by the present invention remain photo stable in aqueous solution in the presence of sunlight. Ionic photo stable silver can be achieved onl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com