Multi-cell single voltage electrolysis apparatus and method of using same

a single-voltage electrolysis and multi-cell technology, applied in the field of high-efficiency electrolysis systems, can solve the problems of limited regional availability, dire consequences for the world's economy, and its vulnerability to disruption of the supply of energy, and achieve the effect of high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

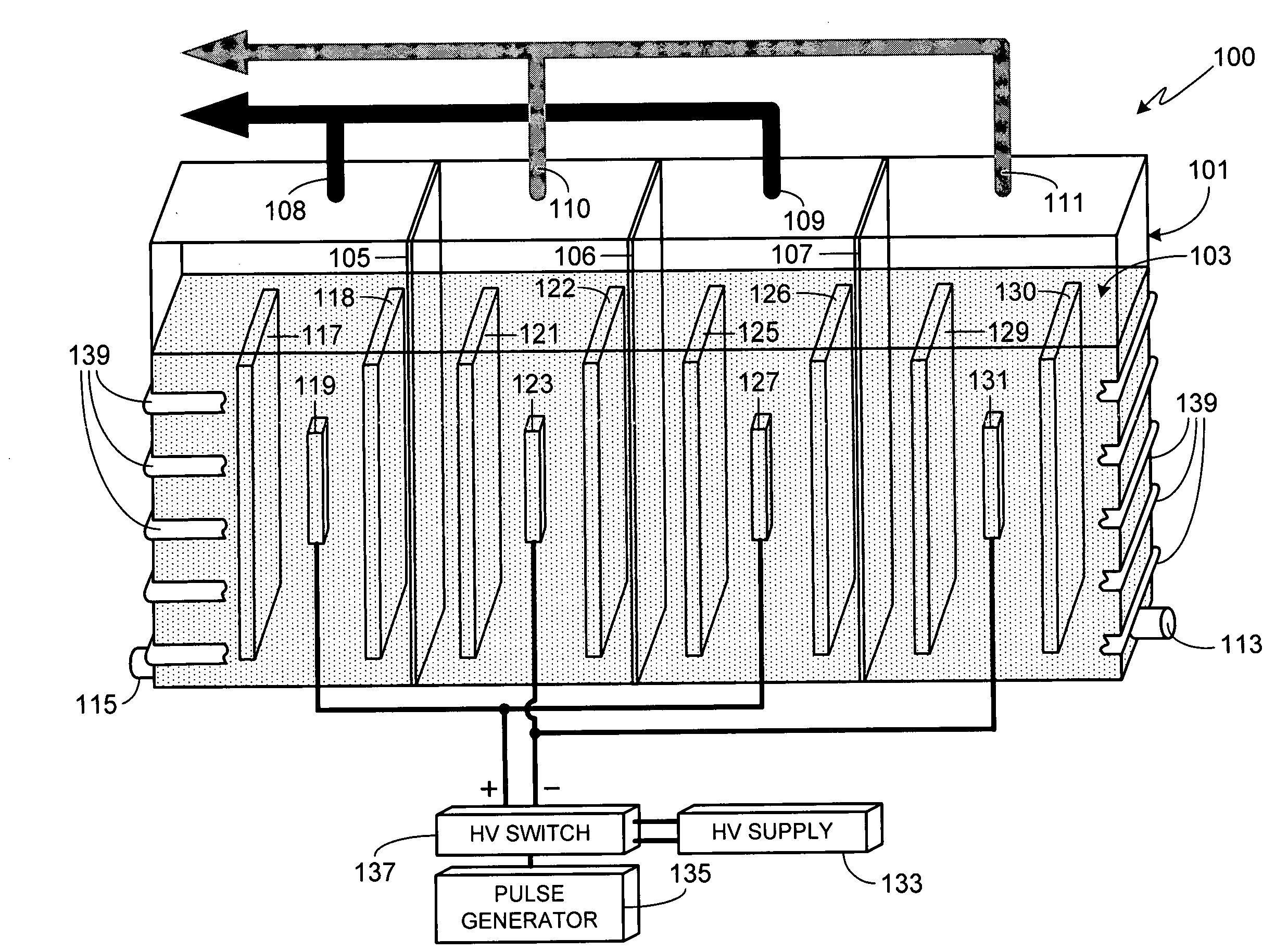

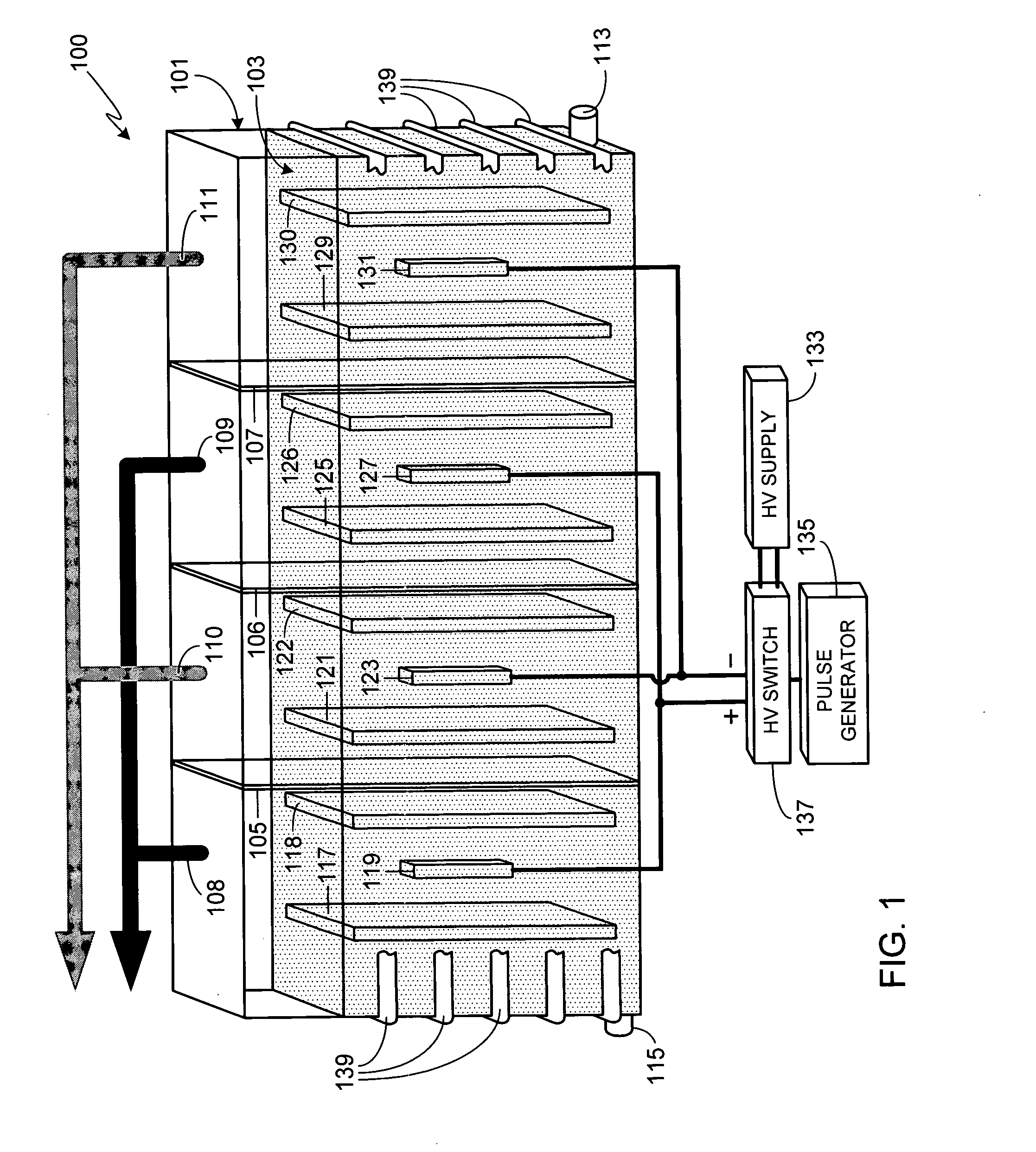

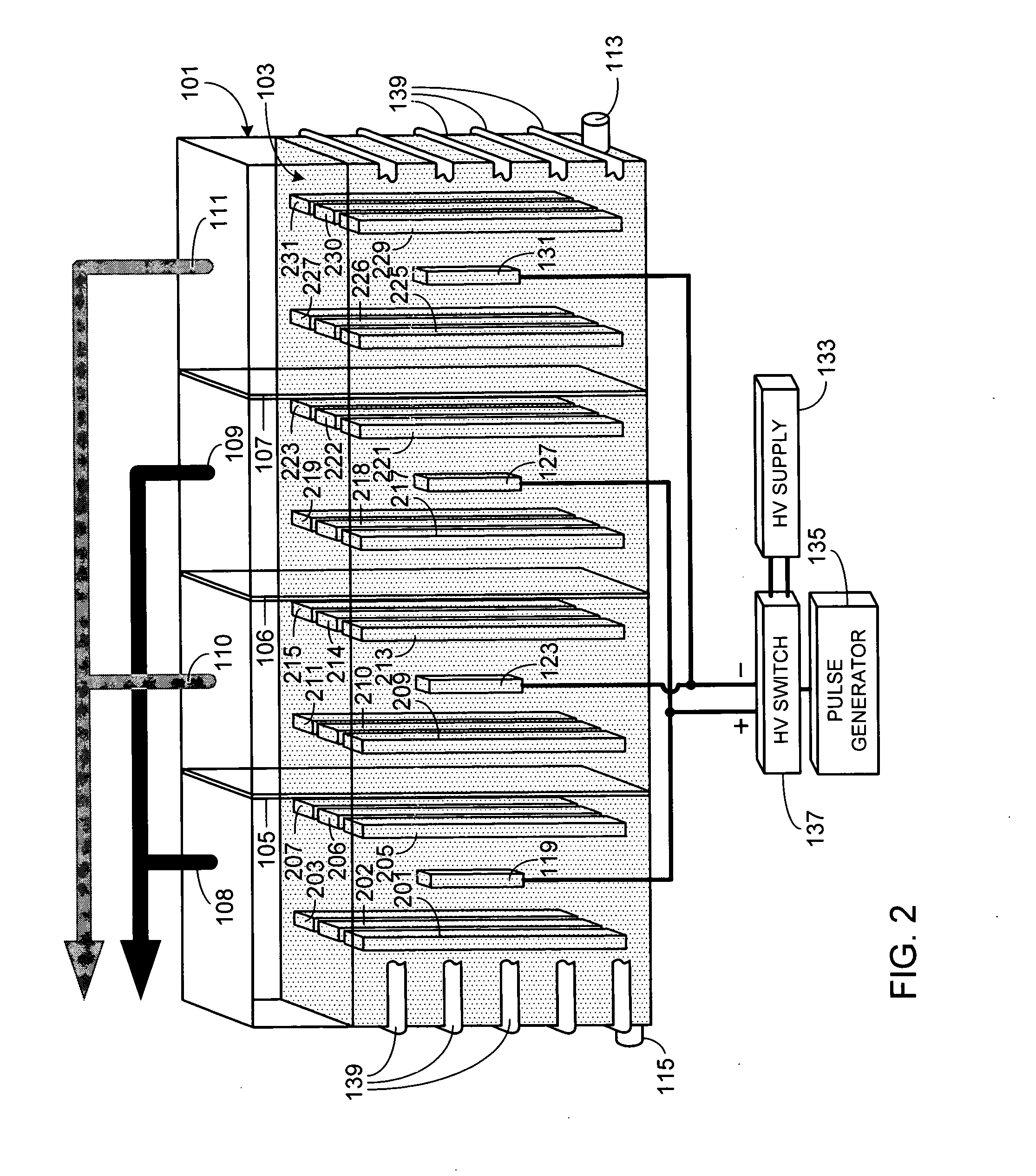

[0027]FIG. 1 is an illustration of an exemplary, and preferred, embodiment of the invention which can be used, for example, as a heat generator. Electrolysis system 100 includes a tank 101 comprised of a non-conductive material, the size of the tank depending primarily upon the desired output level for the system, for example the desired heat production. Although tank 101 is shown as having a rectangular shape, it will be appreciated that the invention is not so limited and that tank 101 can utilize other shapes, for example cylindrical, square, irregularly-shaped, etc. Tank 101 is substantially filled with liquid 103. In at least one preferred embodiment, liquid 103 is comprised of water with an electrolyte, the electrolyte being either an acid electrolyte or a base electrolyte. Exemplary electrolytes include potassium hydroxide and sodium hydroxide. The term “water” as used herein refers to water (H2O), deuterated water (deuterium oxide or D2O), tritiated water (tritium oxide or T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com