Method of and apparatus for conveying molten metals while providing heat thereto

a technology of conveying apparatus and molten metals, which is applied in the direction of casting apparatus, chemical/physical processes, domestic heating, etc., can solve the problems of slow flow of molten metal through the trough, increased risk of metal solidification (or undue cooling) in the trough, and accelerated oxidation of metal at the surface, so as to prevent oxidation and increase heat conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

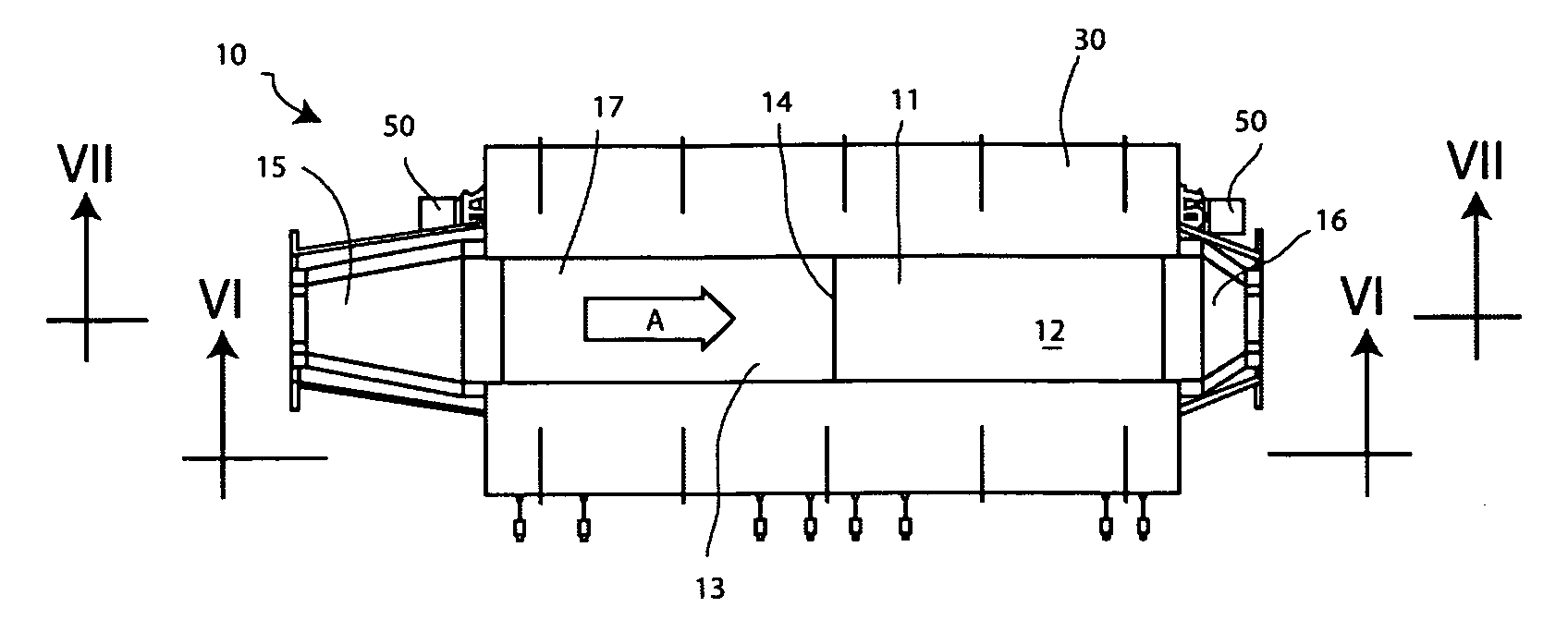

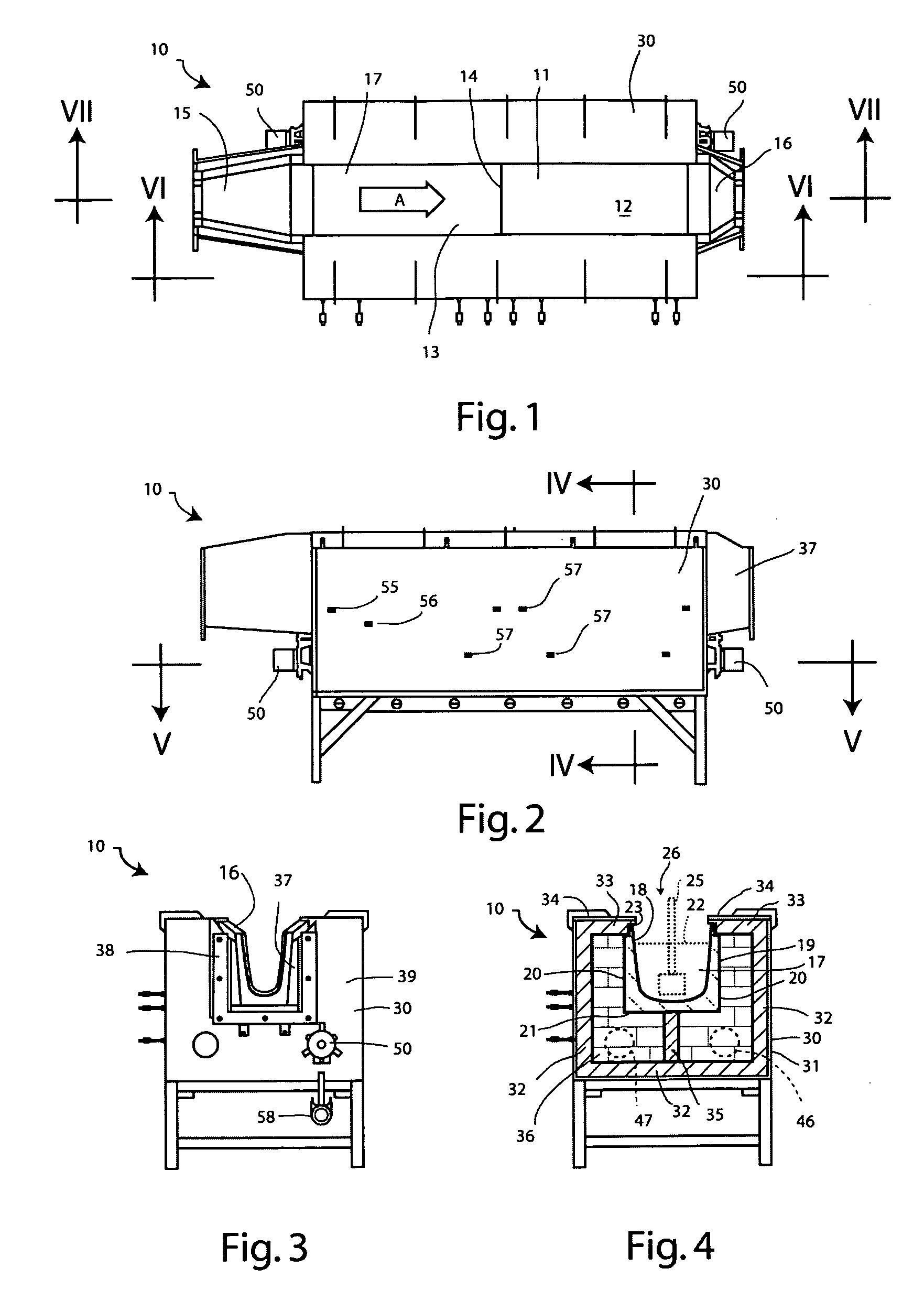

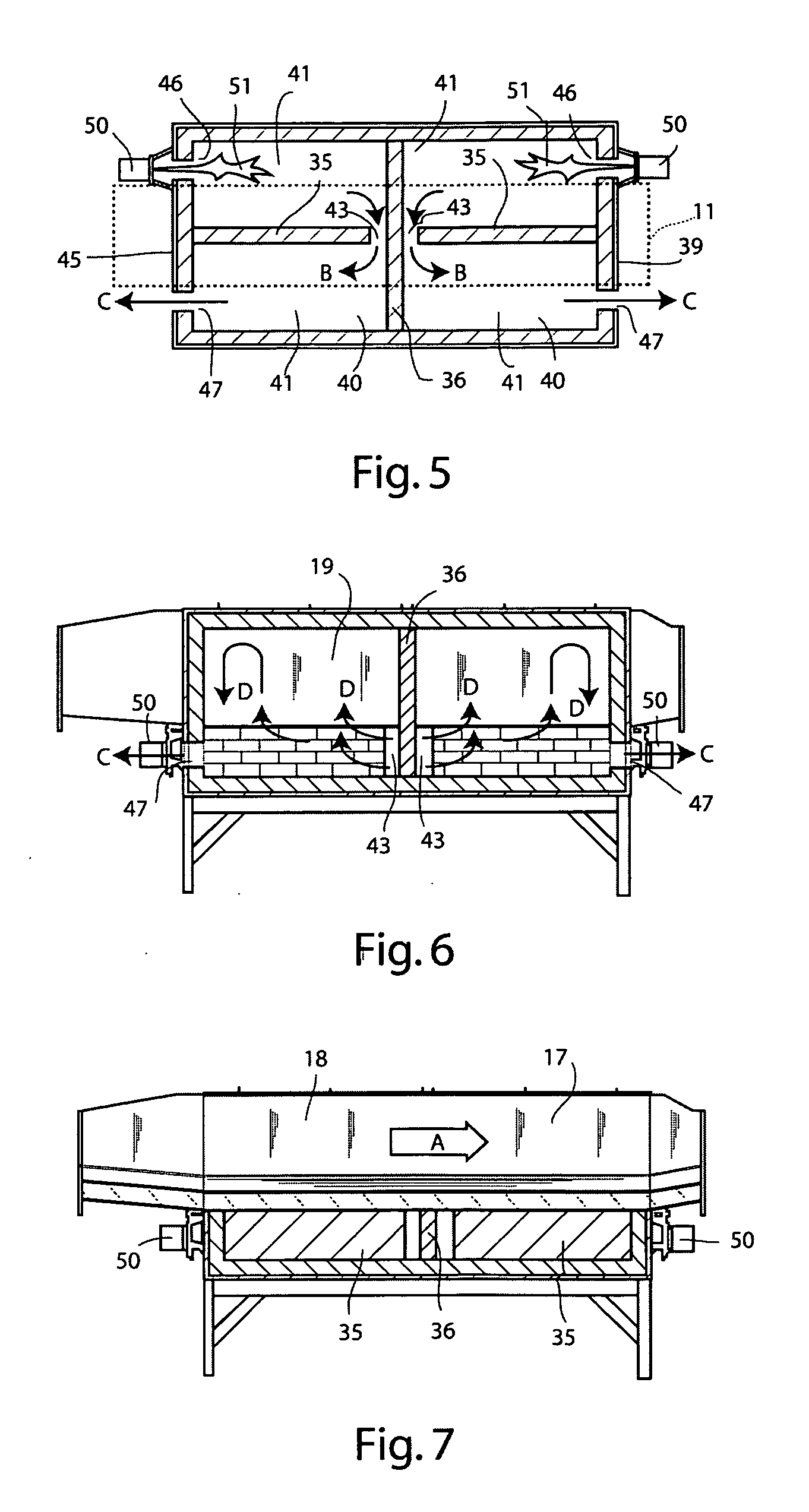

[0031]A first exemplary embodiment of a molten metal conveying apparatus is shown in FIGS. 1 to 7 of the accompanying drawings. This particular embodiment is intended for use with metal degasser nozzles intended for use with molten aluminum or aluminum alloys, thereby forming a compact in-line metal degasser unit which may, for example, be incorporated into a conventional trough or launder leading from a metal melting furnace to a casting apparatus. Other exemplary embodiments may be intended for use with other molten metals.

[0032]The apparatus is indicated generally by reference numeral 10 and includes a section 11 of metal-conveying trough made up of two trough parts 12 and 13 abutting each other at a junction 14. The trough section 11 acts as an elongated channel-forming element that conveys molten metal through the apparatus. Butting up to the trough section 11 at an upstream end is a trough inlet member 15, and butting up to the trough section 11 at a downstream end is a trough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com