Multi-Edge Working Surfaces for Polycrystalline Diamond Cutting Elements

a cutting element and working surface technology, applied in the field of superhard polycrystalline material elements, can solve the problems of imposing a limit on the maximum useful operating temperature of the element, assembly is subjected to very high temperature and pressure, and the element may be subject to thermal degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

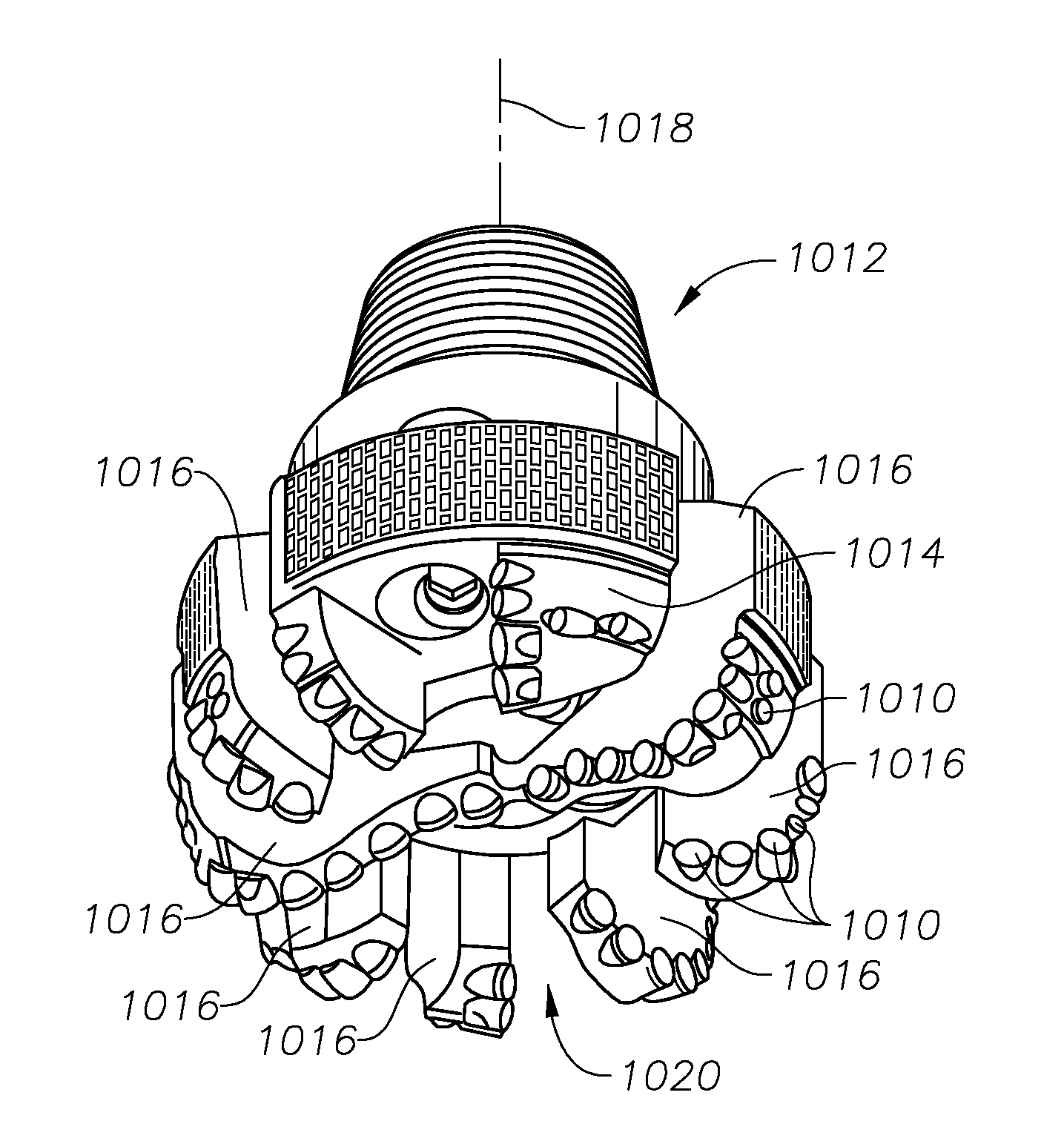

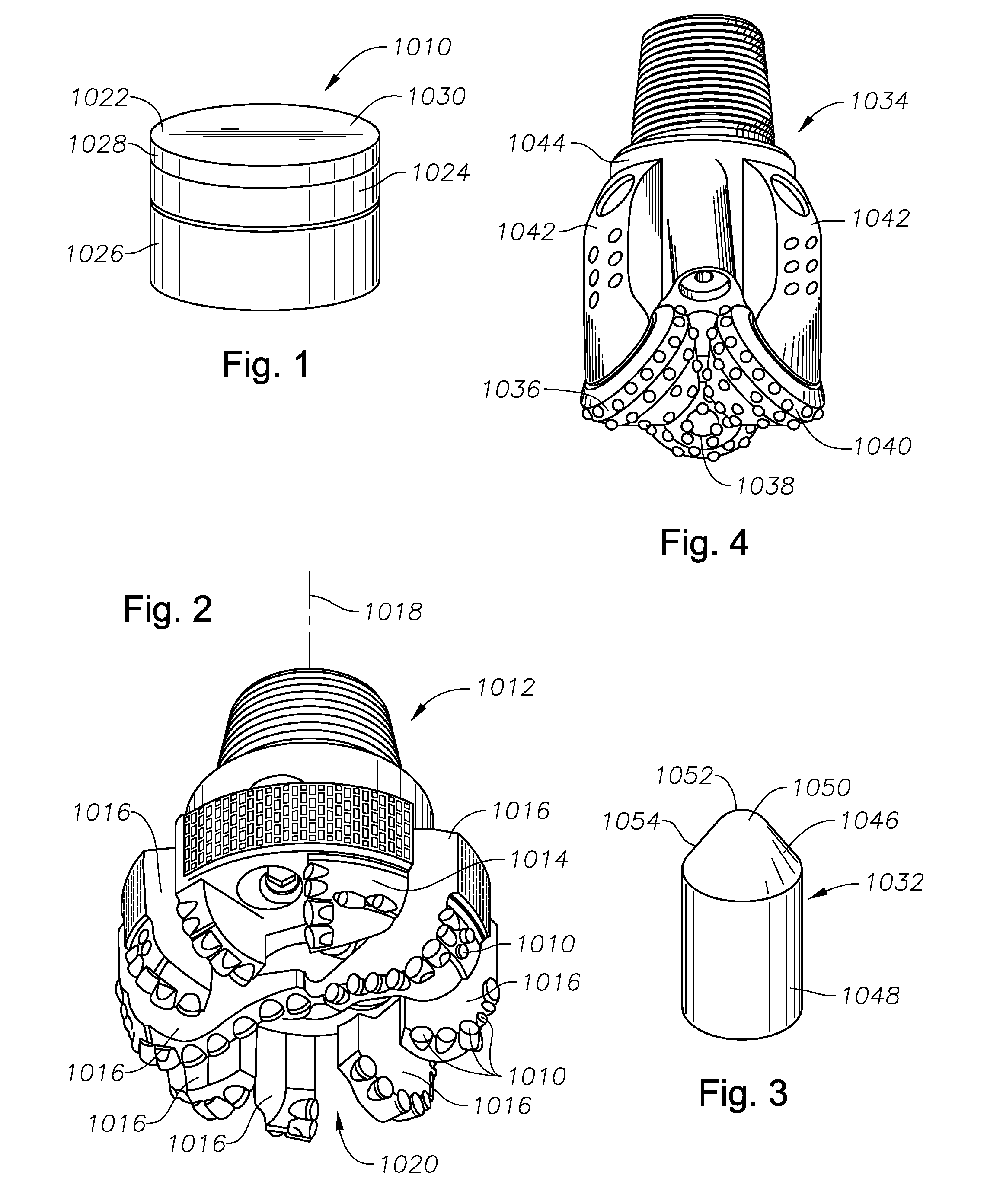

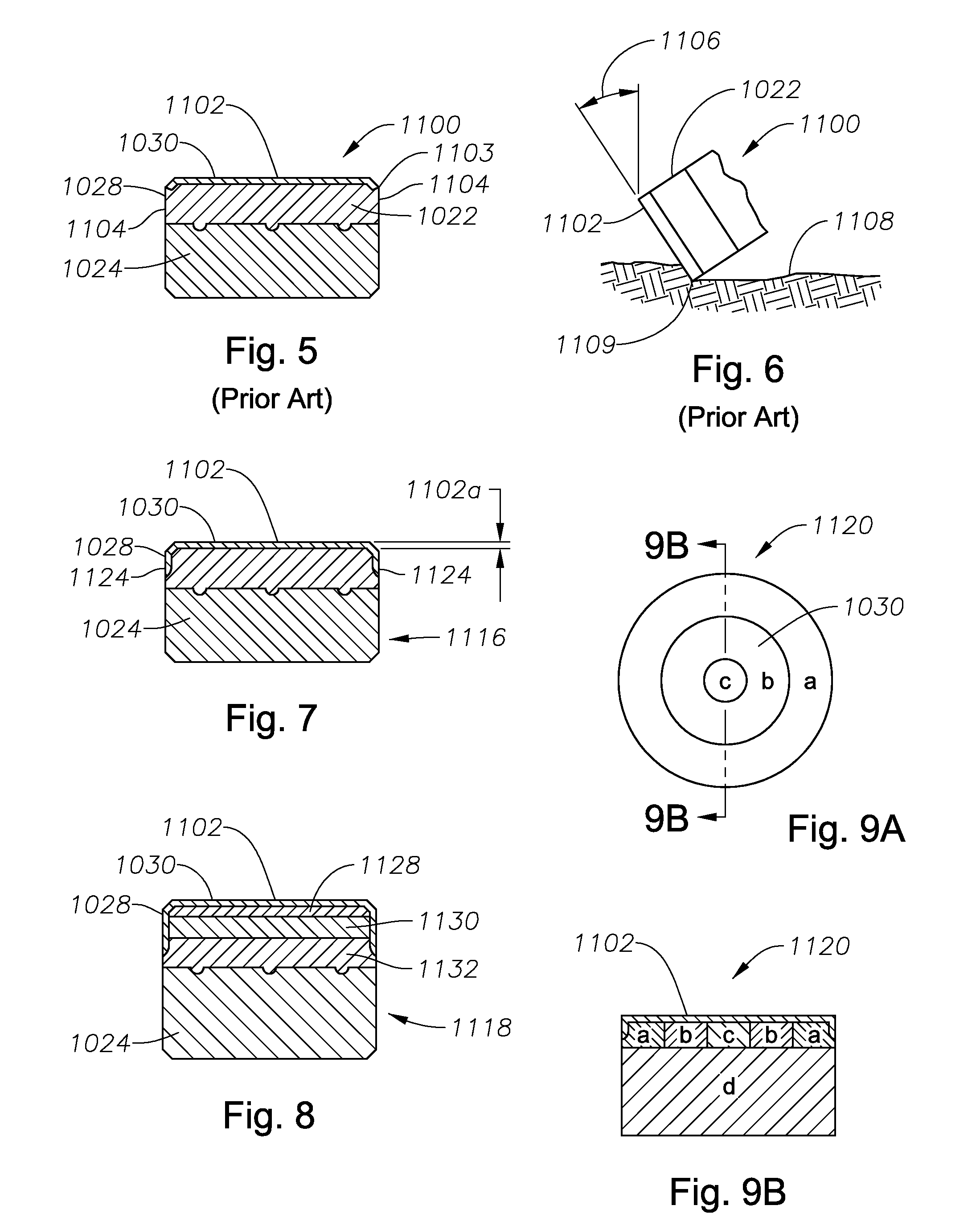

[0040]Referring now to FIGS. 1-4, the polycrystalline diamond and polycrystalline diamond-like (PCD) element 1010 of the present invention may be a preform cutting element 1010 for a fixed cutter rotary drill bit 1012 (as shown in FIG. 1). The bit body 1014 of the drill bit is formed with a plurality of blades 1016 extending generally outwardly away from the central longitudinal axis of rotation 1018 of the drill bit. Spaced apart side-by-side along the leading face 1020 of each blade is a plurality of the PCD cutting elements 1010 of the present invention.

[0041]Typically, the PCD cutting element 1010 has a body in the form of a circular tablet having a thin front facing table 1022 of diamond or diamond-like (PCD) superhard material, bonded in a high-pressure high-temperature press to a substrate 1024 of less hard material such as cemented tungsten carbide or other metallic material. The cutting element 1010 is preformed and then typically bonded on a generally cylindrical carrier 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com