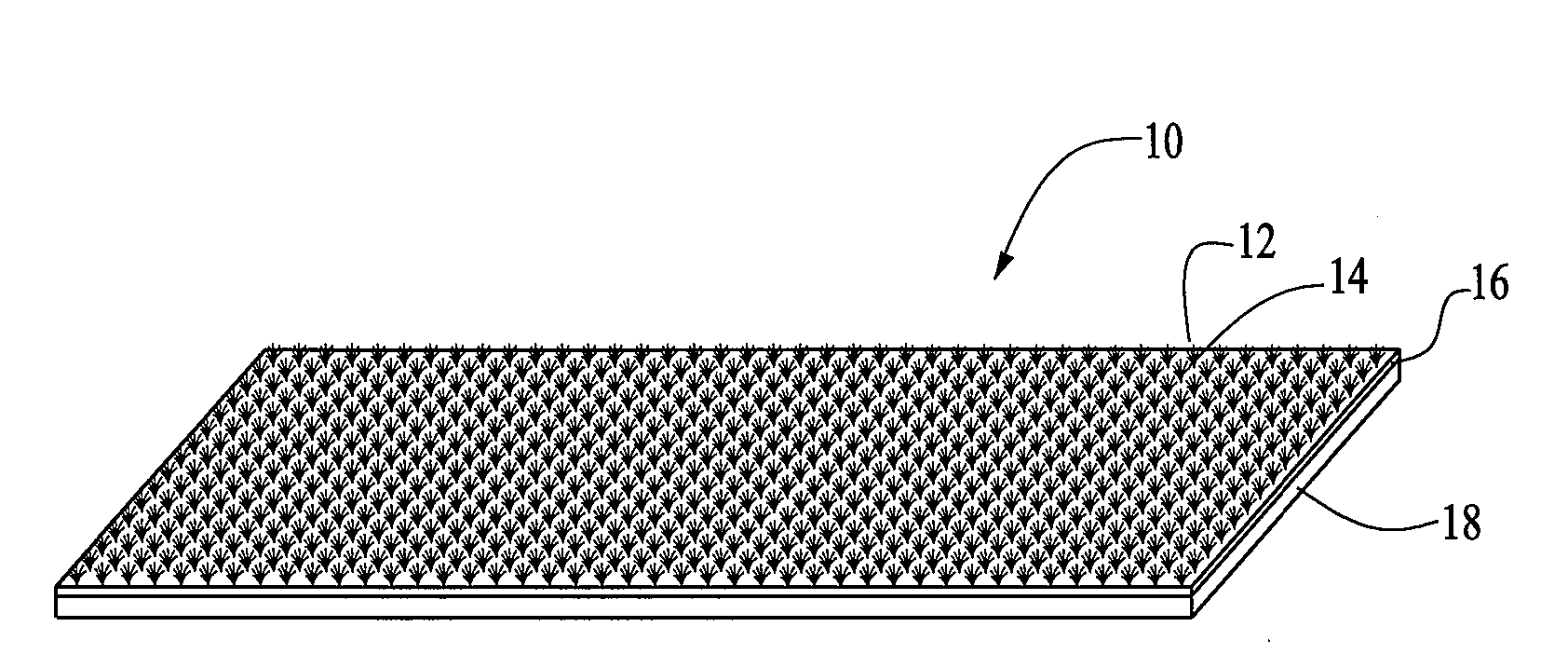

Golf Practice Mat

a golf practice and mat technology, applied in the field of improved golf practice mats, can solve the problems of not being overly successful, not being able to simulate the resistance in give of hitting down and through natural grass, and being easily damaged by repeated hitting of balls during practice, etc., to achieve the effect of low friction coefficient, exceptional feel and low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

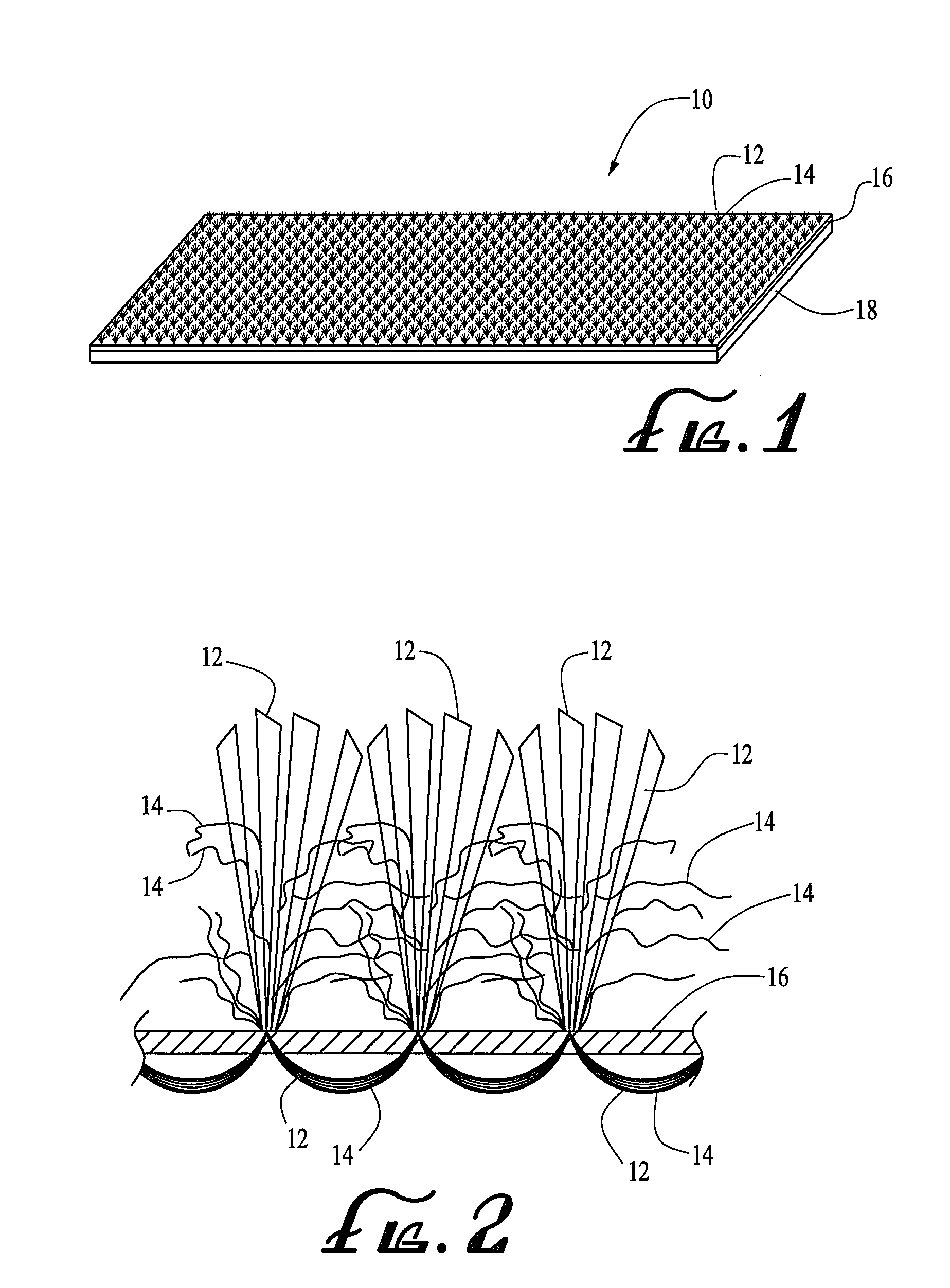

first embodiment

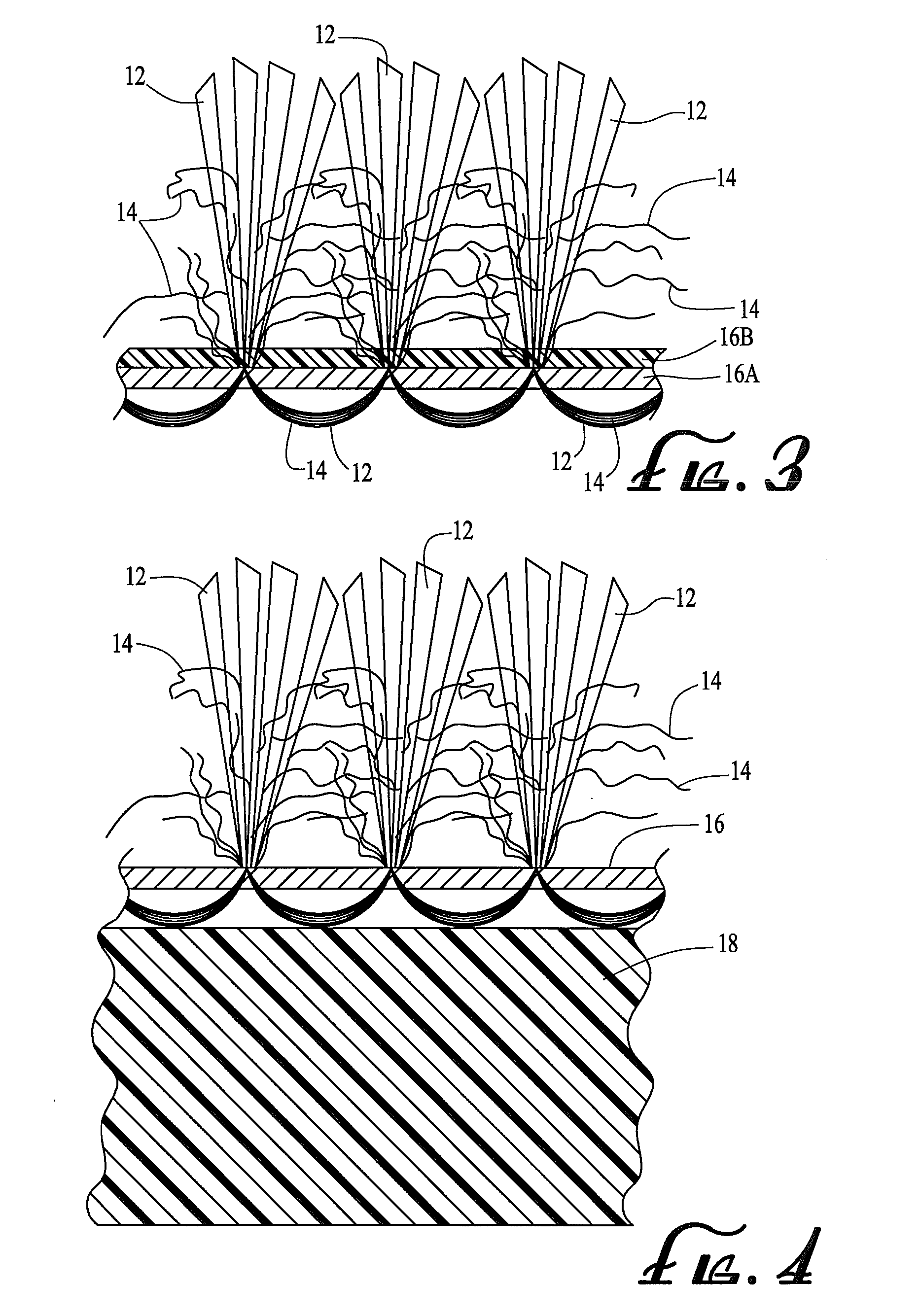

[0021]In the above-described first embodiment of backing 16, the primary backing 16A is formed of a material that provides a dimensionally stable foundation for superior tuftability and pattern definition. It also combines strength with moisture and mildew resistance along with easy handling and long term durability, while offering highly versatile characteristics throughout the manufacturing and installation process. A woven polypropylene material marketed by Propex Fabrics in Dalton, Ga. under the registered trademark POLYBAC® has proved to provide these desired characteristics. This material is of an open weave configuration and has a pick count of 13 (number of weaves per inch). A pick count of about 11-22 would be acceptable to provide the desired flexibility.

[0022]In addition to being made of a denser material so as to prevent adhesive from seeking therethrough, the second or upper backing layer 16B should also provide mechanical stability for the fibers 12 and 14, be tear res...

second embodiment

[0029]In a second and preferred embodiment of the present invention, the backing 16 is of a single layer construction and formed of a durable and mildew resistant and relatively open material to relieve tension in the pile such that when the fibers 12 and 14 are stitched thereon, it will allow the turf to lay flat without curling. In the preferred construction of this second embodiment of the invention, the backing 16 is formed of the same POLYBAC open-weave polypropylene textile material used in the lower layer 16A of the prior embodiment. To avoid seepage of the adhesive through the backing during fabrication, the backing 16 with the fibers 12 and 14 stitched thereon by tufting machine is adhesively bonded to the shock absorbing pad 18 by a process in which the adhesive is applied directly to the upper surface of 18′ of the foam pad 18.

[0030]An example of such a process is schematically illustrated in FIG. 6. As seen therein, a roll 60 of the foam pad material is directed, via a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com