Fabrication methods of a patterned sapphire substrate and a light-emitting diode

a technology of patterned sapphire and substrate, which is applied in the direction of semiconductor devices, electrical equipment, basic electric elements, etc., can solve the problems of increasing current leakage, reducing the power of light and lifetime, and high density of threading dislocations of gan crystals, so as to reduce the cost of etching process, increase the etching speed, and simplify the process of fabricating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

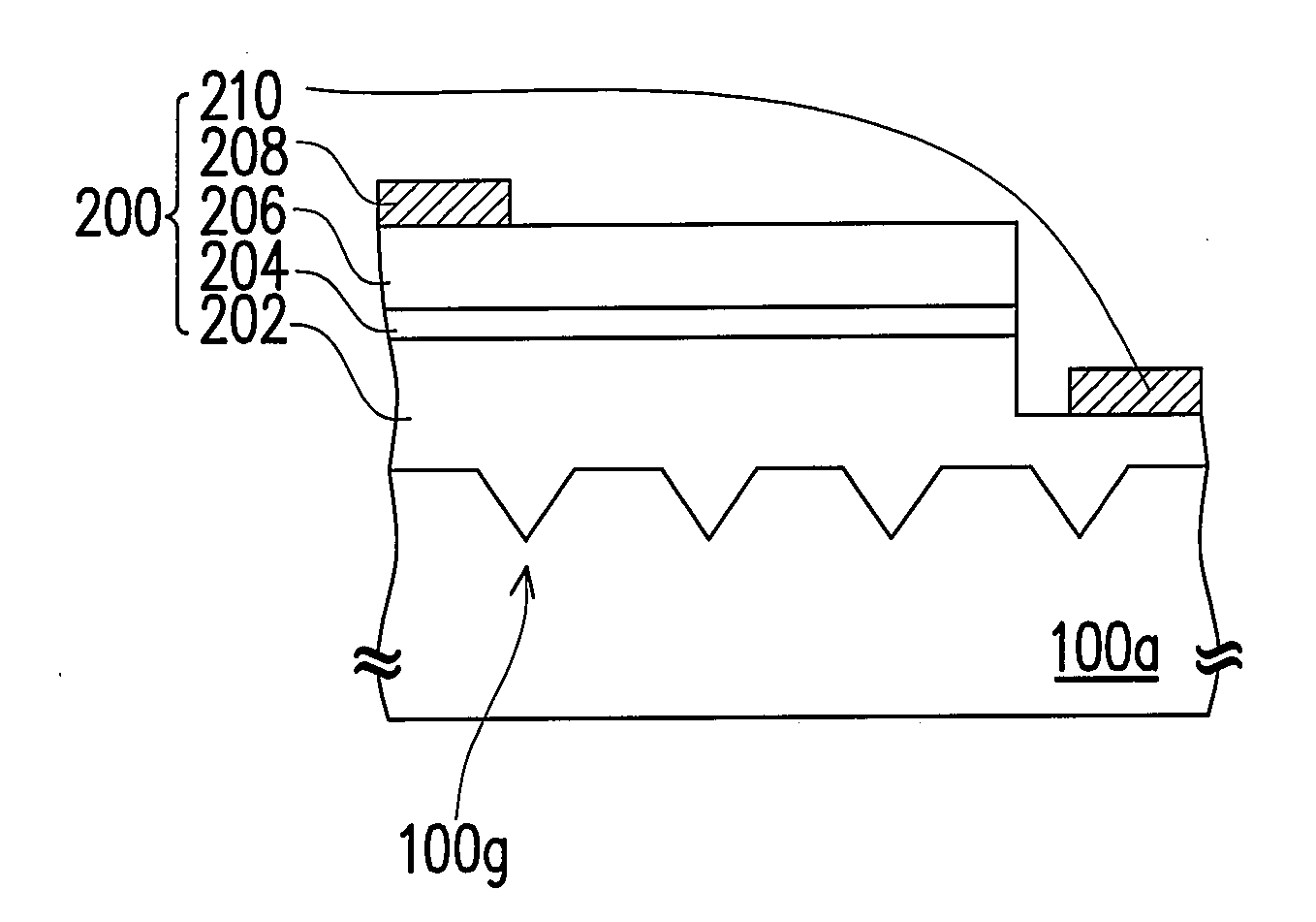

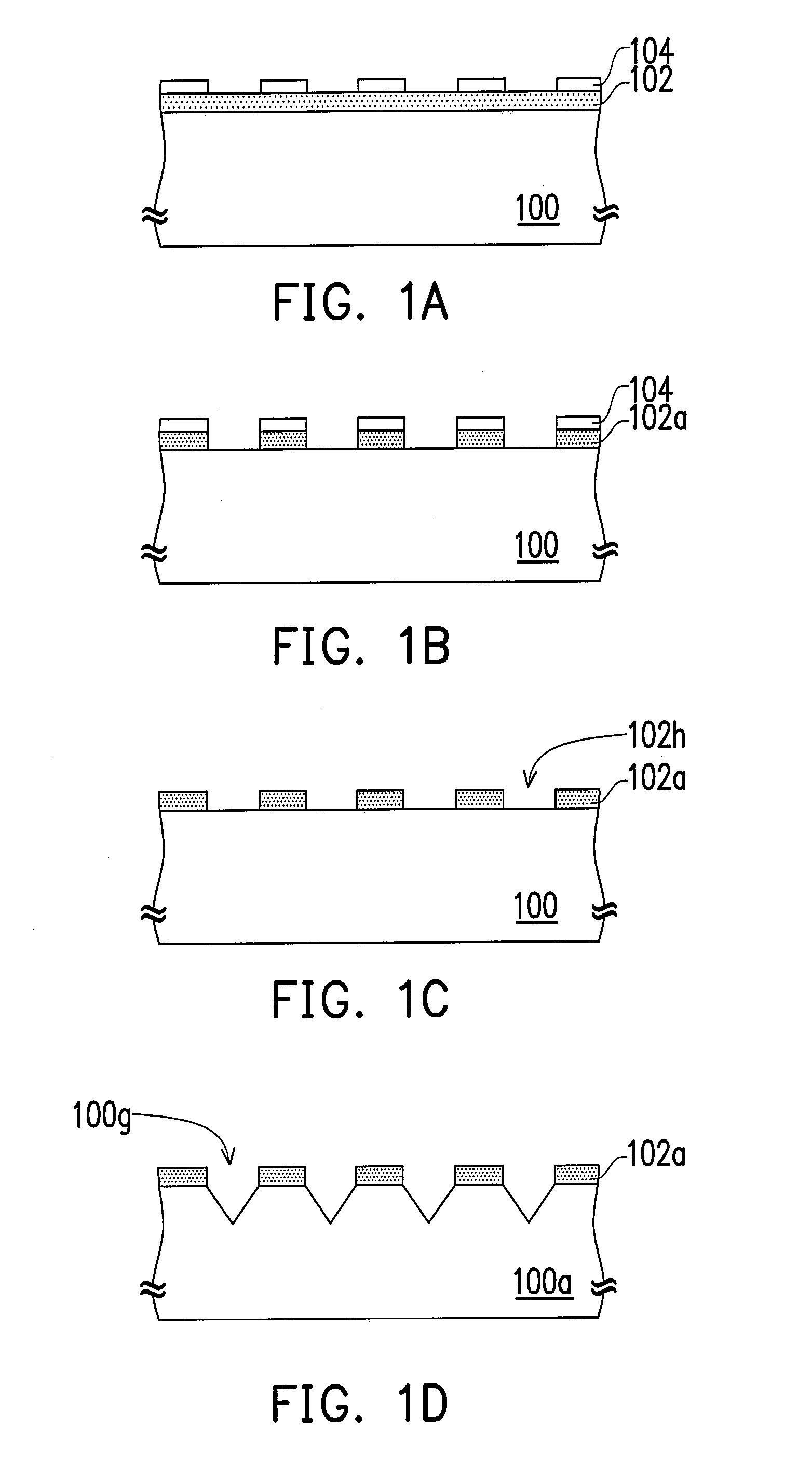

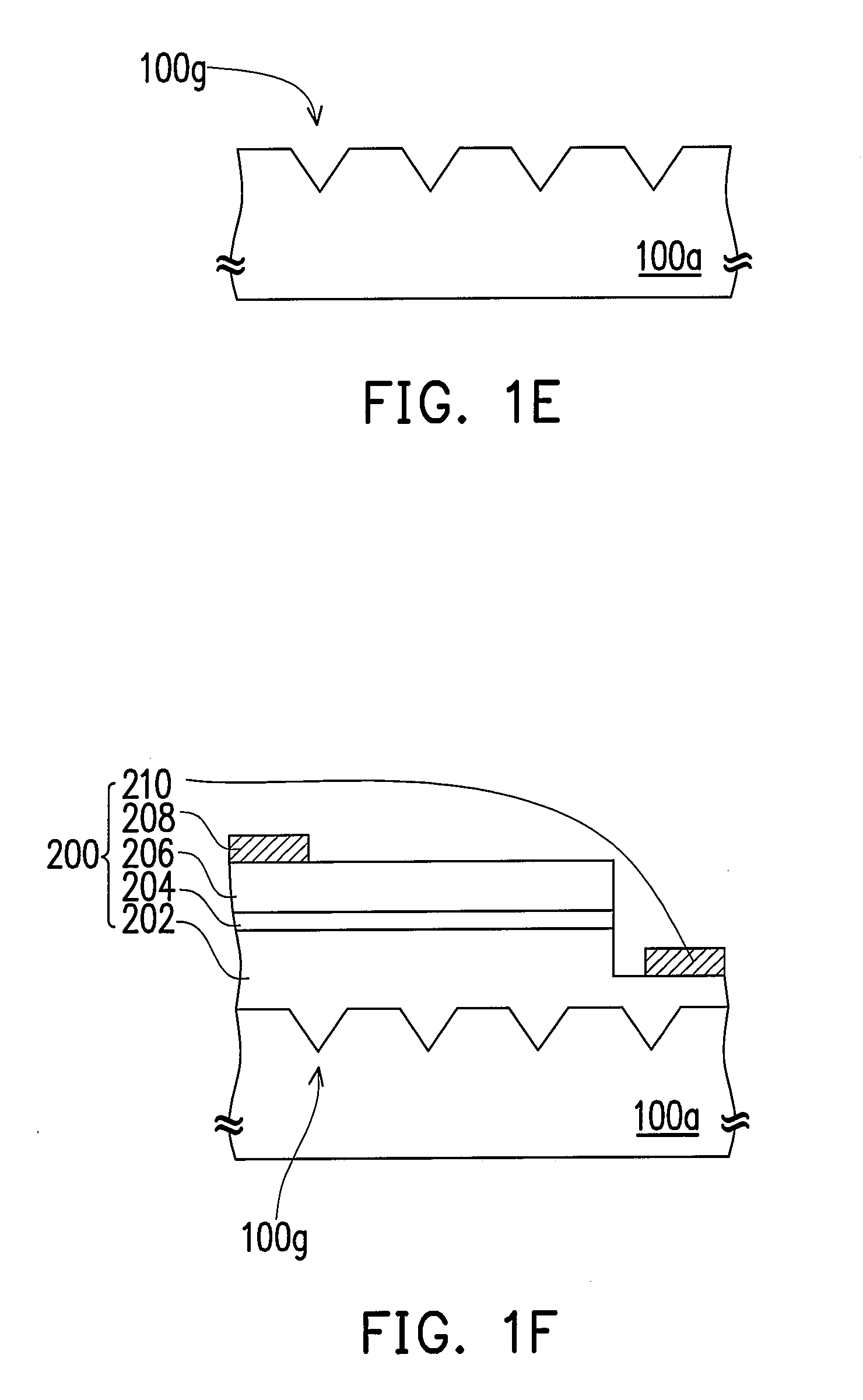

[0023]In order to simplify an etching process for a sapphire substrate, reduce the cost of the etching process, and increase the etching speed, the present invention provides a method using a wet etching process to fabricate a patterned sapphire substrate. In the following specification, the foresaid wet etching process is named “the first wet etching process” to distinguish from other wet etching processes. The pure sulfuric acid or the mixture containing sulfuric acid and phosphoric acid is used as an etchant in the first wet etching process. The mechanism of using sulfuric acid (H2SO4) and phosphoric acid (H3PO4) as the etchant to etch the sapphire substrate (Al2O3) is shown respectively as the following formula (1) and (2).

Al2O3+3H2SO4→Al2(SO4)3+3H2O (1)

Al2O3+2H3PO4→2AlPO4+3H2O (2)

[0024]In this embodiment, if the etchant is the mixture of sulfuric acid and phosphoric acid, rather than the pure sulfuric acid, it is preferable that the composition ratio of sulfuric acid is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com