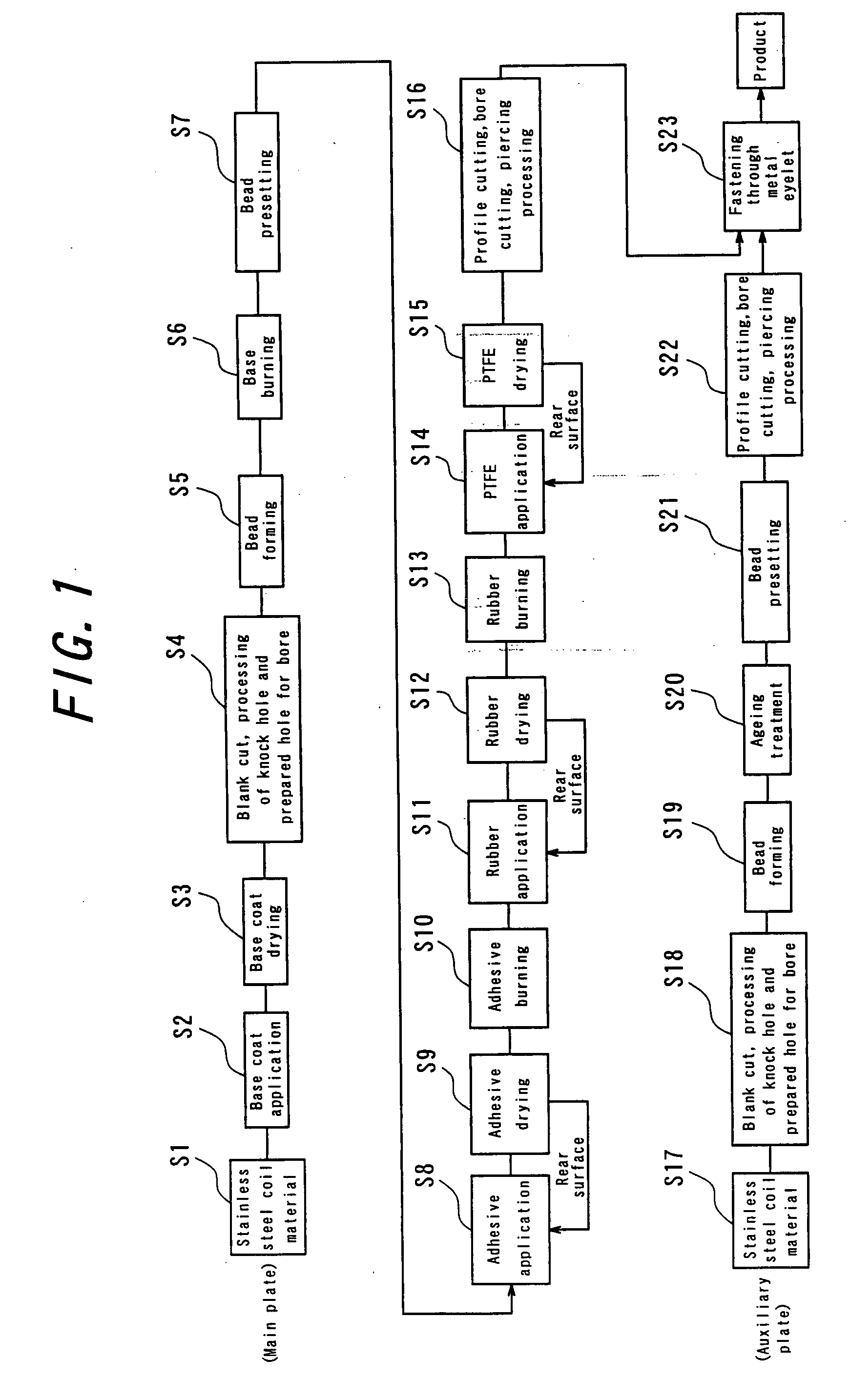

[0010] According to the metal gasket manufacturing method of the present invention, the metal plate having the low-temperature age-hardening characteristics is used as the metal plate of the base plate formed by providing the rubber

coating layer on the surface of the metal plate with the base coat and the

adhesive interposed therebetween. The base coat is applied to the metal plate of the base plate, and the base coat is fixed to some extent by

drying at the temperature lower than the low aging temperature of the metal plate. Subsequently, after press-working of the circular beads is performed on the metal plate, the metal plate is age-hardened while burning the base coat at the low aging temperature of the metal plate of the base plate. Thus, since the press-working of the circular beads is performed on the metal plate in the state where the

hardness is still low, even if the rise angle of the circular beads is increased, it is possible to effectively prevent occurrence of cracks and roughness in hem portions of the circular beads. Moreover, the

hardness is increased by age-hardening the metal plate in conjunction with the subsequent base coat burning. Thus, it is possible to realize the metal gasket having the circular beads which are hardly broken even when crushed.

[0011] Moreover, according to the metal gasket manufacturing method of the present invention, by use of the metal plate having the low-temperature age-hardening characteristics, aging treatment is performed by base coat burning which can lower the temperature compared with heating of the rubber coating layer. Thus, it is possible to realize the metal gasket which can prevent occurrence of coarse deposits leading to fatigue fracture and has an excellent durability.

[0012] Furthermore, if there is already a convex portion of the circular bead in the metal plate when the base coat is applied, the base coat before

drying is likely to flow along a slope of the convex portion. Accordingly, the base coat is likely to be accumulated around a bottom of the convex portion. Thus, the state of the base coat applied tends to be varied. On the other hand, according to the metal gasket manufacturing method of the present invention, after the base coat is applied to the flat metal plate and is fixed to some extent by

drying, the press-working of the circular beads is performed on the metal plate. Accordingly, there is no dripping or accumulation of the base coat compared with the case where the base coat is applied after the press-working of the circular beads is performed on the metal plate. Thus, there is no variation in the state of the base coat applied. Consequently,

adhesive strength of the rubber coating layer can always be set stable.

[0013] Note that, in the metal gasket manufacturing method of the present invention, it is preferable that presetting of the circular beads be performed after the metal plate is age-hardened while burning the base coat at the low aging temperature of the metal plate of the base plate. Accordingly, burning of the base coat is done before presetting in which the circular beads, which are press-formed in the blank plate, are pressed once by use of a press die and are returned by

repulsion force of those beads. Thus, it is possible to prevent peeling of the base coat due to

rubbing against the press die in the presetting.

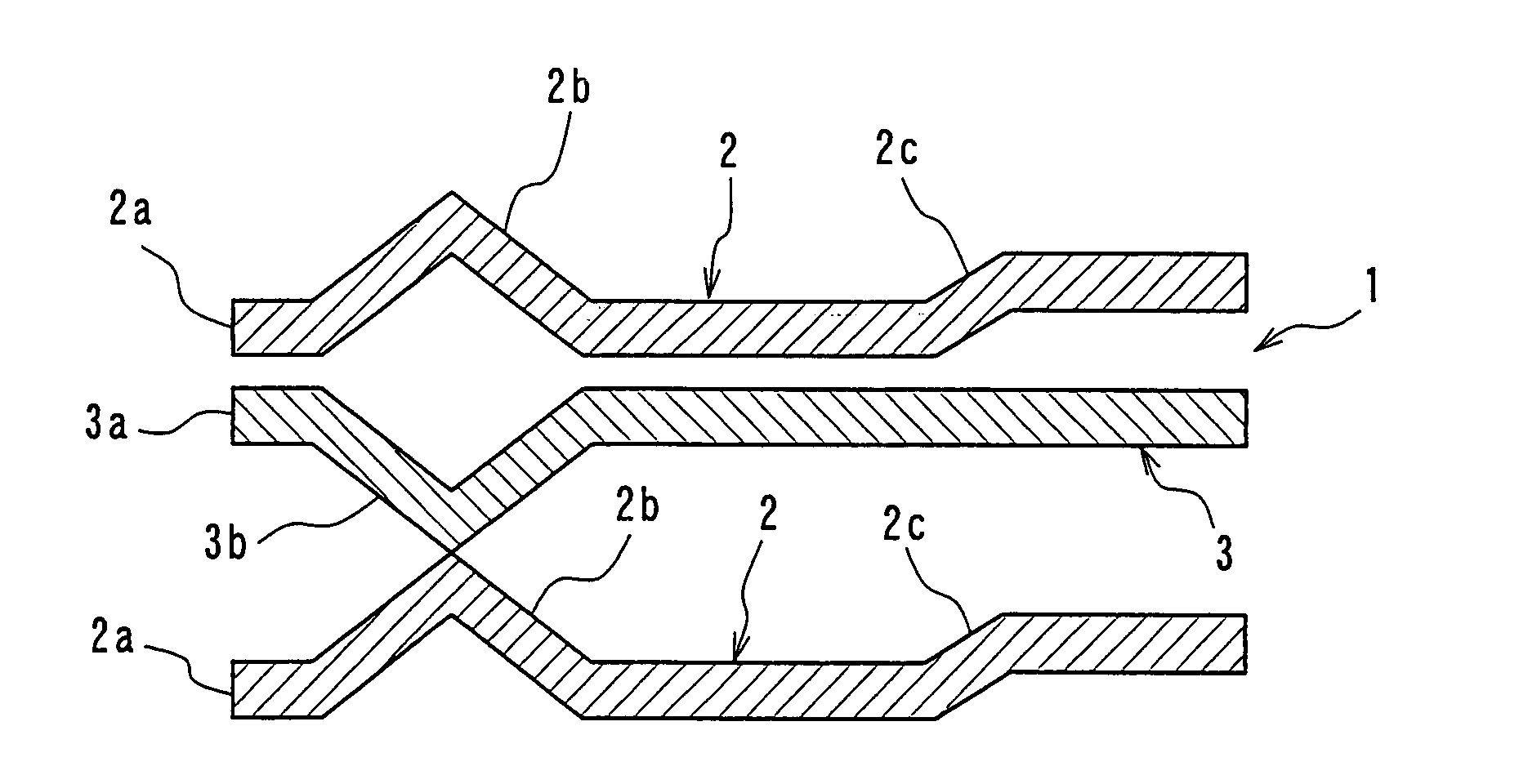

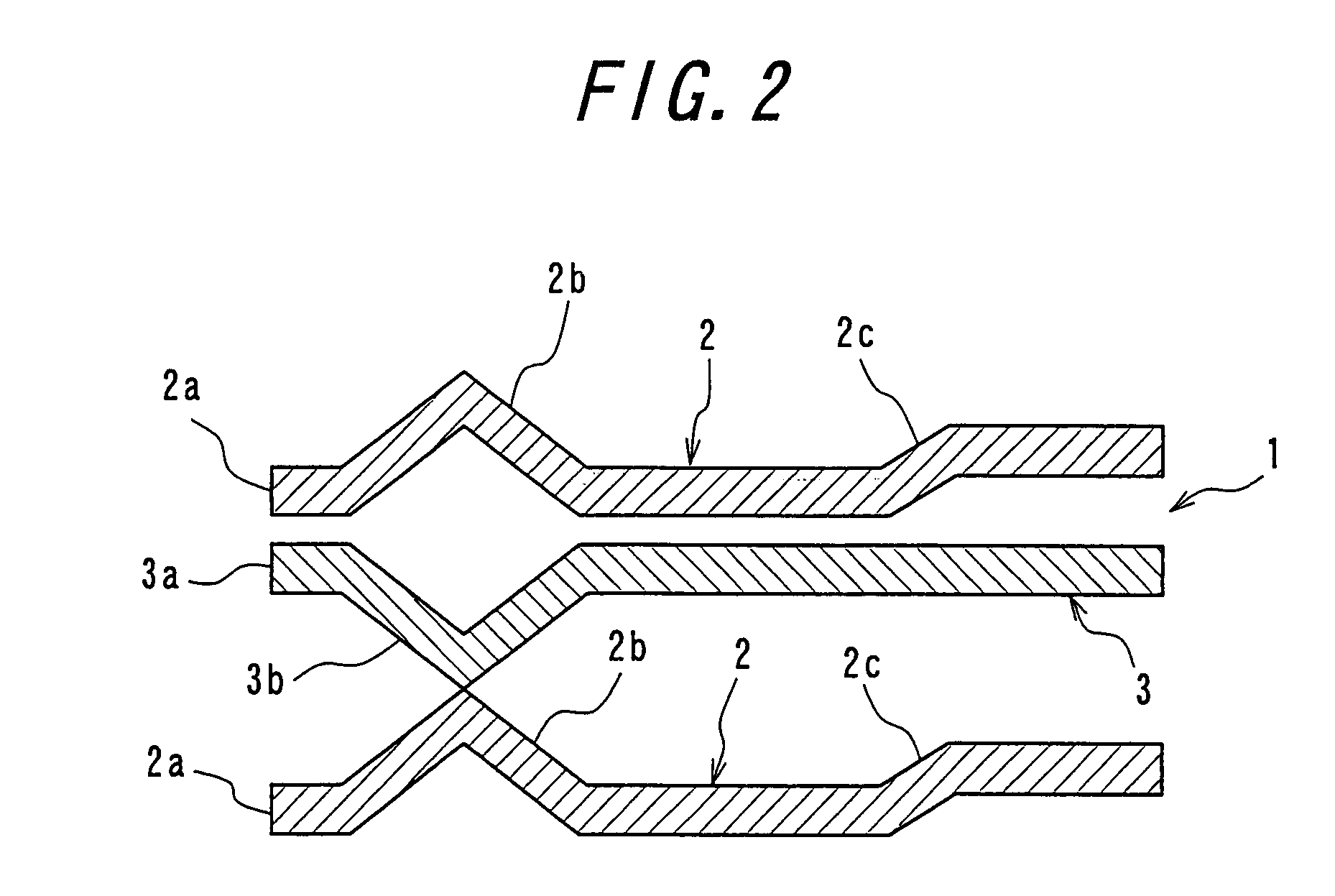

[0014] Moreover, in the metal gasket manufacturing method of the present invention, it is preferable that, in the case where the metal gasket further includes an auxiliary plate which is made of a metal plate having no rubber coating layer and has at least fluid passage holes and circular beads surrounding the fluid passage holes, the metal plate having the low-temperature age-hardening characteristics be used as the metal plate of the auxiliary plate, and the metal plate be age-hardened at the low aging temperature of the metal plate of the auxiliary plate after press-working of the circular beads on the metal plate of the auxiliary plate. Accordingly, stacking of the circular beads of the base plate on the circular beads of the auxiliary plate makes it possible to increase an amount of elastic crushing in a circular bead portion of the gasket without increasing much rise angles of the respective circular beads of the base plate and the auxiliary plate. Moreover, even if a gap between gasket mounting planes is increased by

high pressure in the fluid passage holes, linear pressure of the circular beads can be maintained to achieve high sealing performance.

[0015] Furthermore, in the metal gasket manufacturing method of the present invention, it is preferable that, as conditions of aging treatment for the metal plate having the low-temperature age-hardening characteristics, the temperature be set to not less than 200° C. and less than 250° C., and the length of time be set to 1 to 5 minutes. Accordingly, the aging treatment is performed by base coat burning using a temperature lower than that of heating of the rubber coating layer. Thus, it is possible to realize a metal gasket which can prevent occurrence of coarse deposits leading to fatigue fracture and has an excellent durability.

Login to View More

Login to View More