[0023] In the CMP-apparatus retainer ring according to claim 2, the portion to be held of the back surface is held, so that the retainer ring can be held without deforming the pressure surface. Therefore, polishing is conducted with held in this state, thus helping make the pressure surface's

surface roughness extremely fine.

[0024] In the CMP-apparatus retainer-ring manufacturing method according to claim 3, after the shaped surface other than the pressure surface is wrought so as to have a predetermined measurement, the pressure surface is machined and polished (lapped). Therefore, the pressure surface which has undergone

machining or the like is not deformed in the following working. Furthermore, it is subjected to

machining or the like in a state where the retainer ring is held without given an external-circumference pressure and an internal-circumference pressure. This prevents such a hold from deforming the pressure surface. Moreover, through

machining (such as

cutting and

grinding), the pressure surface's flatness and

surface roughness reach a specific measurement (level), and thereafter, polishing is conducted. This helps conduct such polishing desirably. As a result, the pressure surface can be finished off so as to have a high flatness and an extremely-low surface roughness.

[0025] In the CMP-apparatus retainer-ring manufacturing method according to claim 4, in accordance with the material or size of the retainer ring, the kind of

slurry (

abrasive) or the like, the pressure or the rotational speed by the pressing means, or the

slurry supply, is regulated. Therefore, the retainer ring's pressure surface can be polished to a high flatness and an extremely-low surface roughness.

[0026] In the CMP-apparatus retainer-ring manufacturing method according to claim 5, break-in working is conducted, so that the polish pad (such as a cloth) of the polishing apparatus is suited (flattened and fined down) and stabilized. Therefore, in the following polishing, the retainer ring's pressure surface can be wrought well (so as to have a high flatness and an extremely-low surface roughness).

[0027] In the CMP-apparatus retainer-ring manufacturing method according to claim 6, the machining and the polishing are conducted with holding only the side of the back surface of the retainer ring. Therefore, this hold can be prevented from deforming the pressure surface, thus working the pressure surface desirably.

[0028] In the CMP-apparatus retainer-ring manufacturing method according to claim 7, the portion to be held which is formed in the back surface of the retainer ring is held, and in this state, the pressure surface is machined. Therefore, the retainer ring's hold can be prevented from deforming the pressure surface, thus machining the pressure surface desirably.

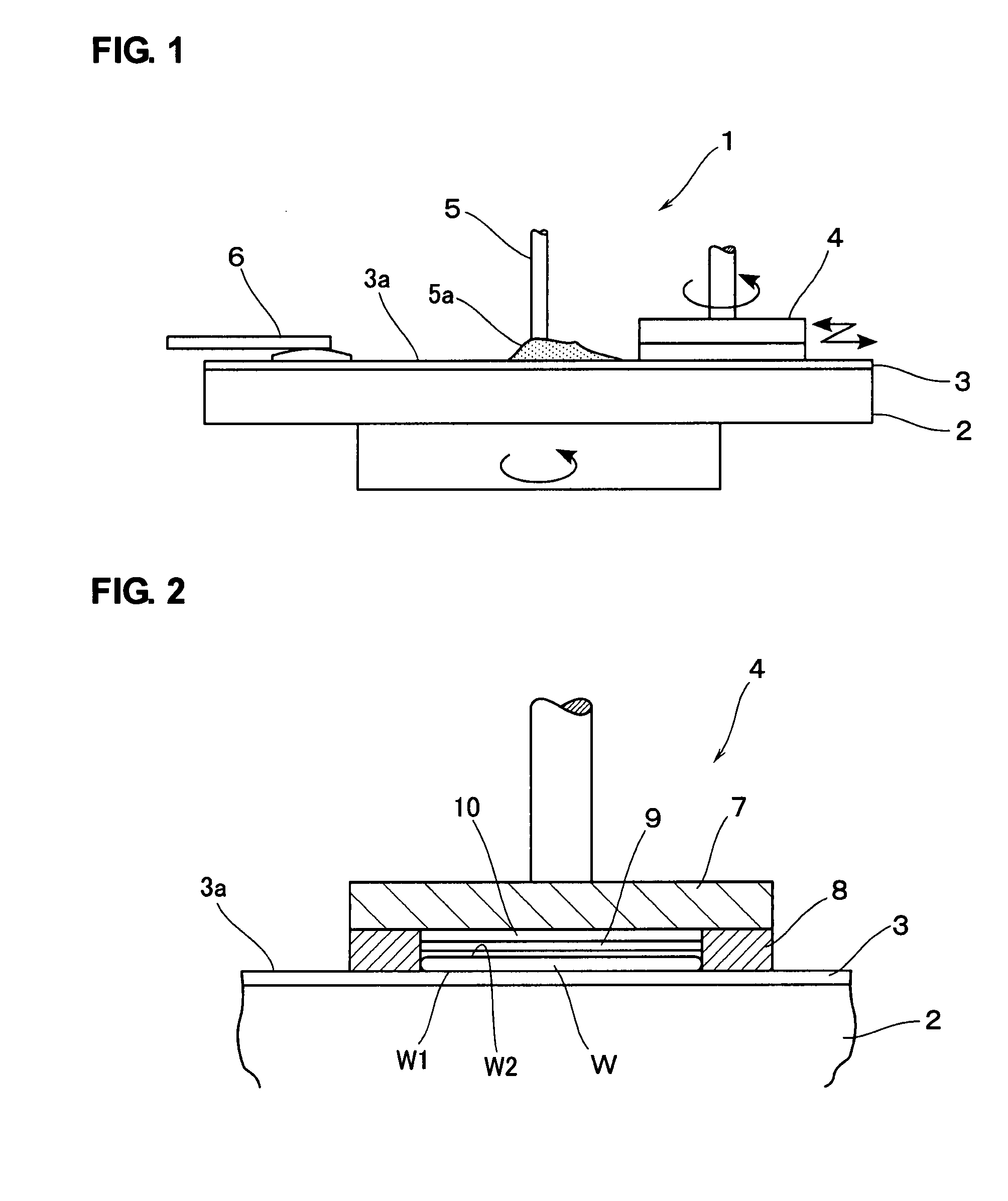

[0029] In the CMP-apparatus retainer-ring manufacturing method according to claim 8, the side of the back surface of the machining jig which holds the retainer ring is supported by the polishing jig. Therefore, this support can be prevented from deforming the retainer ring's pressure surface. Besides, the polishing can be conducted in a state where the retainer ring is held on the machining jig. In other words, the machining and the polishing can be continuously conducted without removing the retainer ring from the machining jig. This helps maintain the machining jig's holding accuracy and holding stability. As a result, the pressure surface can be properly polished.

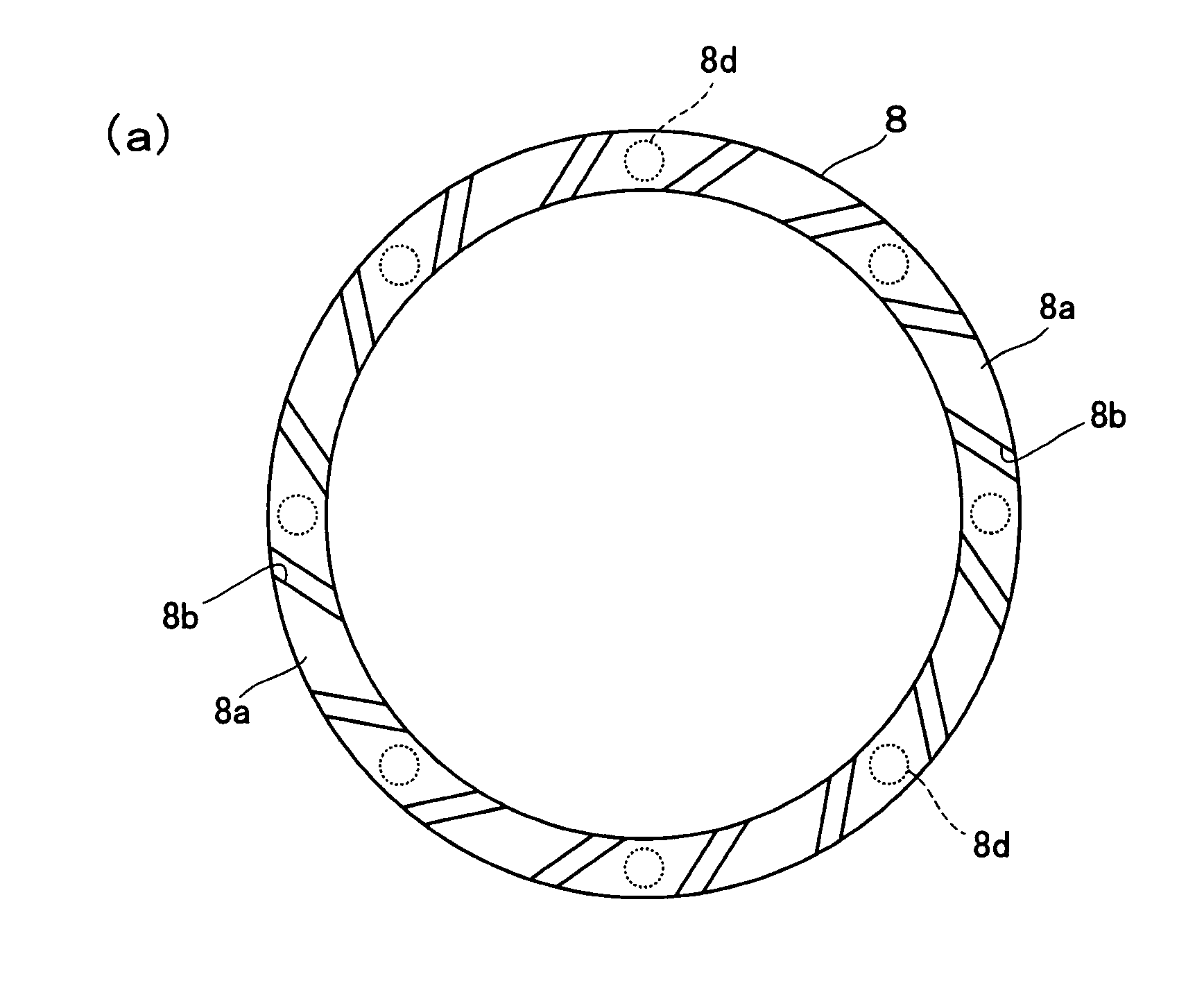

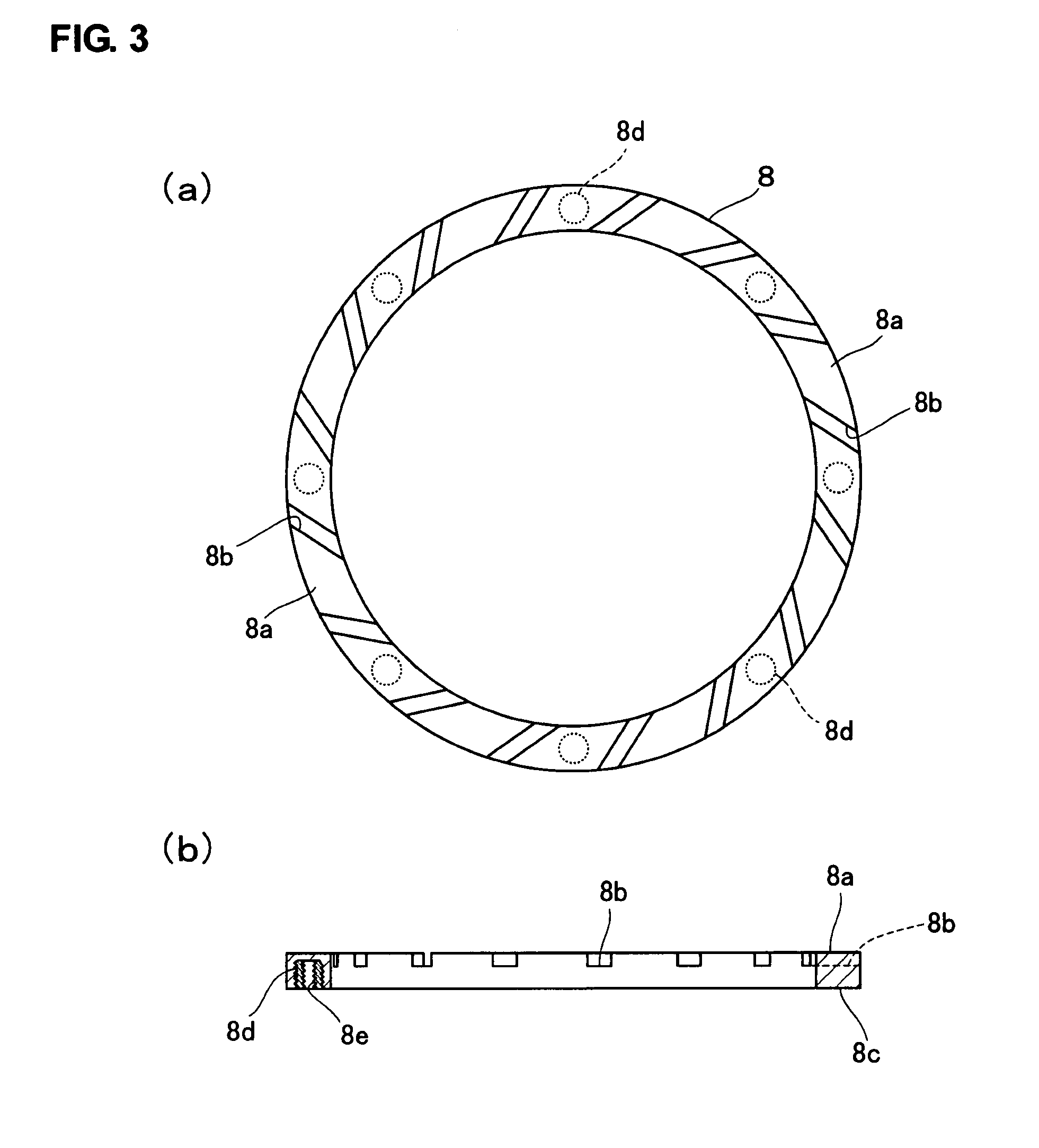

[0030] In the CMP-apparatus retainer-ring machining jig according to claim 9, the portion to be held which is formed in the back surface of the retainer ring is held by the machining jig. Therefore, this hold can be prevented from deforming the retainer ring's pressure surface. In addition, the back surface of the retainer ring comes into surface contact with the attachment surface of the machining jig, and in this state, the retainer ring is held on the machining jig. Consequently, at the time of machining, the retainer ring's pressure surface becomes more stable. As a result, the pressure surface can be appropriately machined.

[0031] In the CMP-apparatus retainer-ring polishing jig according to claim 10, the side of the back surface of the machining jig which holds the retainer ring is supported by the polishing jig. Therefore, this support can be prevented from deforming the retainer ring's pressure surface. Besides, the polishing can be conducted in a state where the retainer ring is held on the machining jig. Besides, the supporting portion is fitted to the

peripheral surface of the machining jig, so that the machining jig (the retainer ring) can be prevented from shifting sideward. Simultaneously, it supports the back surface of the machining jig (the back surface of the retainer ring), so that a working force applied to the retainer ring's pressure surface is properly supported. This helps stabilize the pressure surface at the time of polishing. As a result, the pressure surface can be suitably polished.

[0032] In the CMP apparatus according to claim 11, in terms of the retainer ring, its pressure surface's surface roughness is set to a center-line average roughness of 0.01 μm or below. Therefore, in practice, the time taken for a break-in polish can be effectively restrained to the minimum. Specifically, in this retainer ring, the pressure surface's surface roughness indicates an extremely small value of 0.01 μm or below. Thereby, from immediately after the retainer ring has been attached to the holding head, the polish pad's polish surface is flattened and fined down desirably with the pressure surface. This helps obtain a suitable polishing performance, without giving any break-in polish or only by giving a short-time break-in polish. As a result, the time and labor taken for such a break-in polish can be kept down to the minimum. Effectively in practice, this makes it possible to enhance the production availability of wafers.

Login to View More

Login to View More  Login to View More

Login to View More