Compound semiconductor-on-silicon wafer with a thermally soft insulator

a technology of semiconductors and insulators, applied in the field of composite semiconductors on silicon wafers with thermally soft insulators, can solve the problems of high substrate cost, drive fabrication cost, and lattice mismatch between si and gan, and achieve the effect of avoiding wafer deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

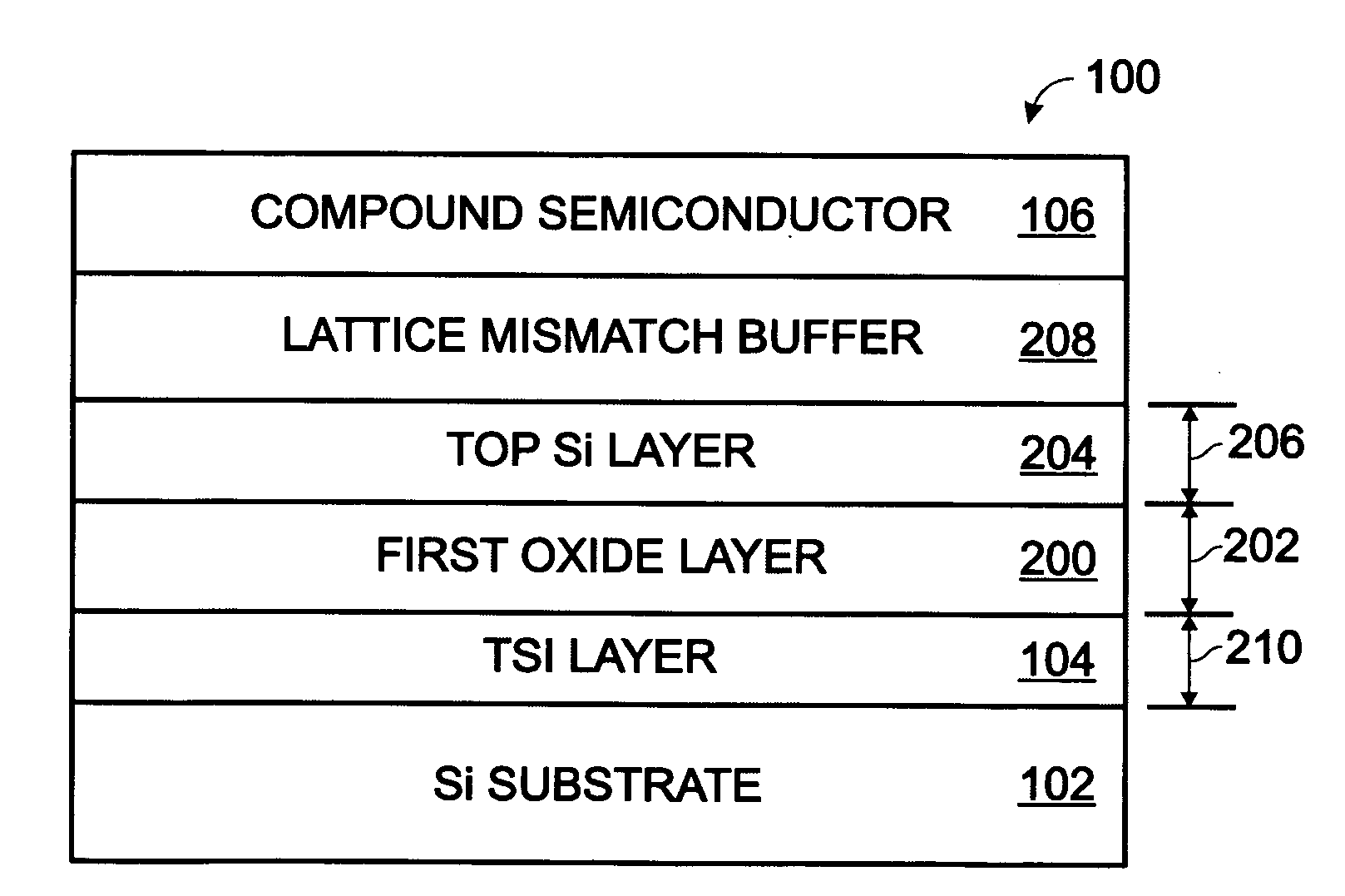

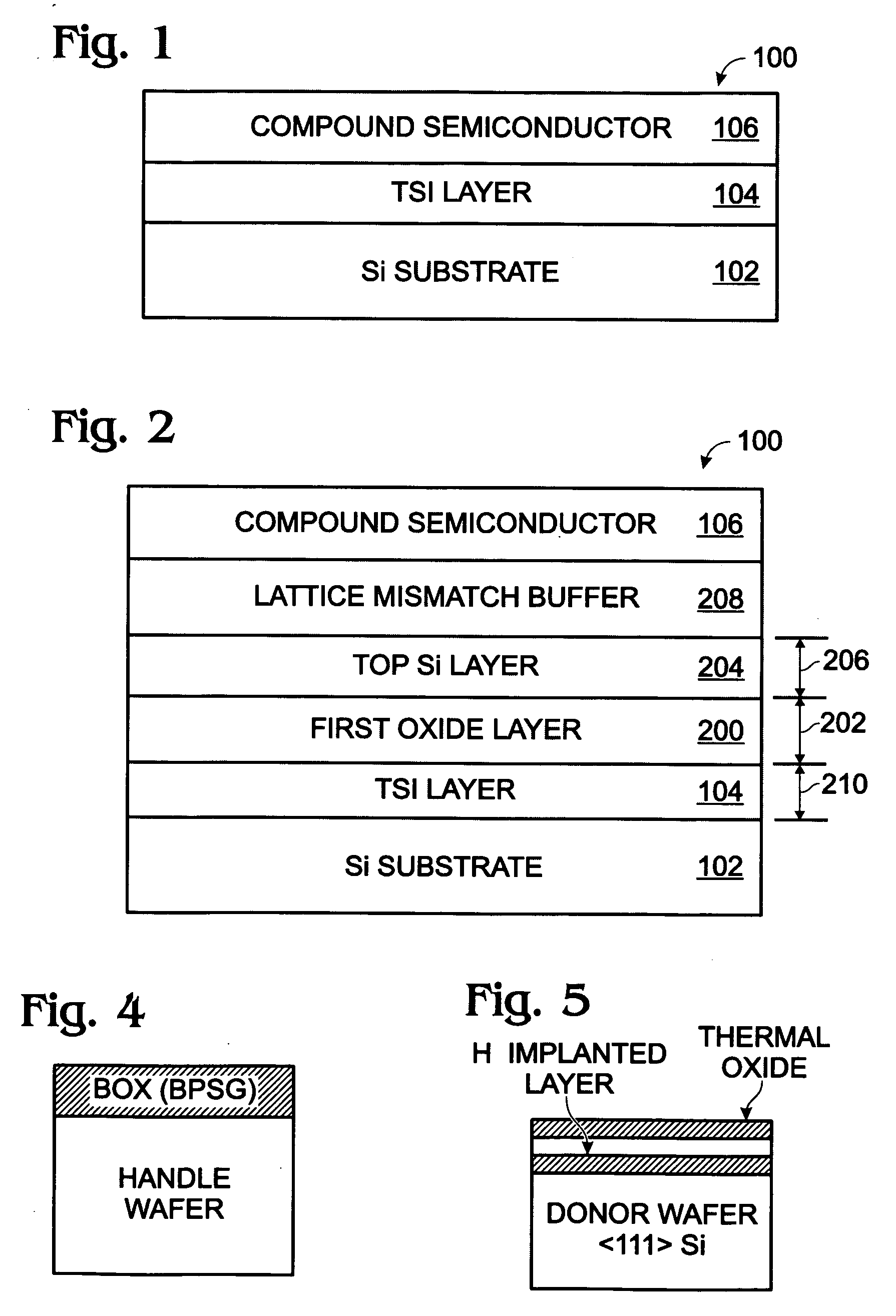

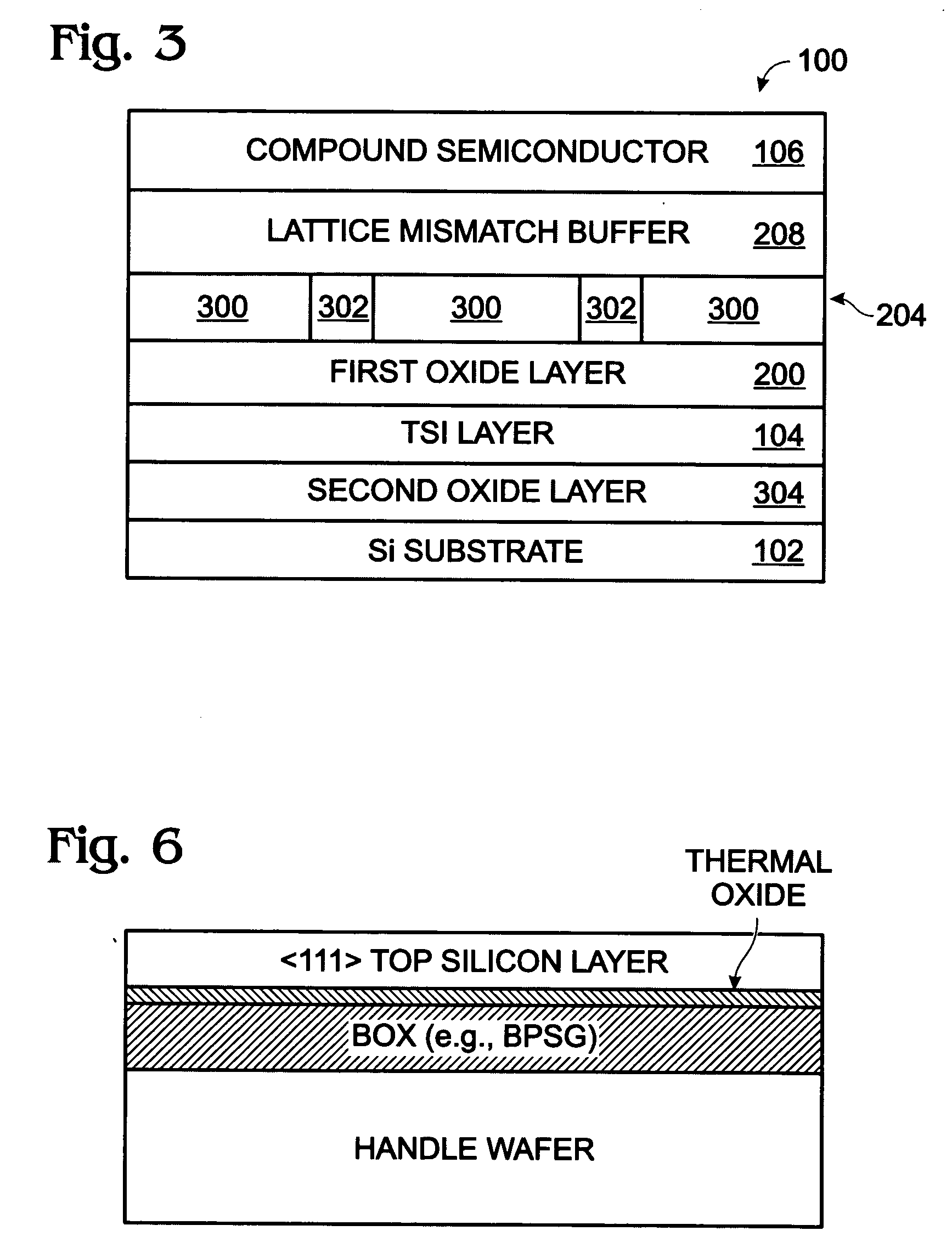

[0019]FIG. 1 is a partial cross-sectional view of a compound semiconductor-on-silicon (Si) wafer with a thermally soft insulator. In a simple aspect, the thermally soft insulated (TSI) wafer 100 comprises a Si substrate 102, a thermally soft insulator layer 104 overlying the Si substrate 102, and a compound semiconductor layer 106 overlying the thermally soft insulator layer 104. The thermally soft insulator 104 has a liquid phase temperature lower than the liquid phase temperatures of Si 102 or the compound semiconductor 106.

[0020]The thermally soft insulator (TSI) layer 104 has a flow temperature in the range of about 500° C. to 900° C., where the flow temperature is greater than the solid phase temperature and less than the liquid phase temperature. The TSI insulator layer 104 may be considered to be mechanically soft at the flow temperature, soft enough to isolate any differences in thermal expansion between the Si substrate 102 and the compound semiconductor 106. That is, the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com