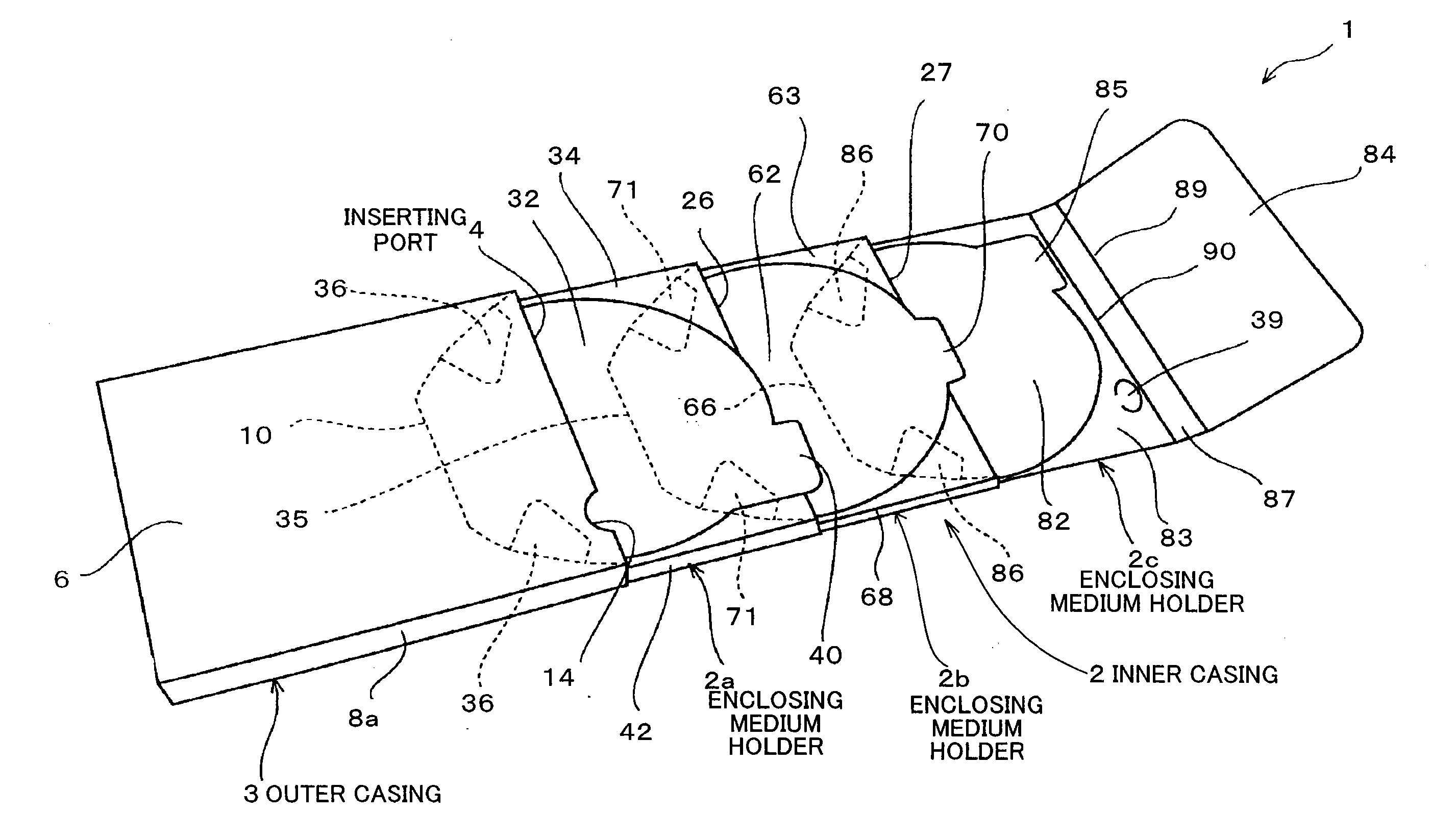

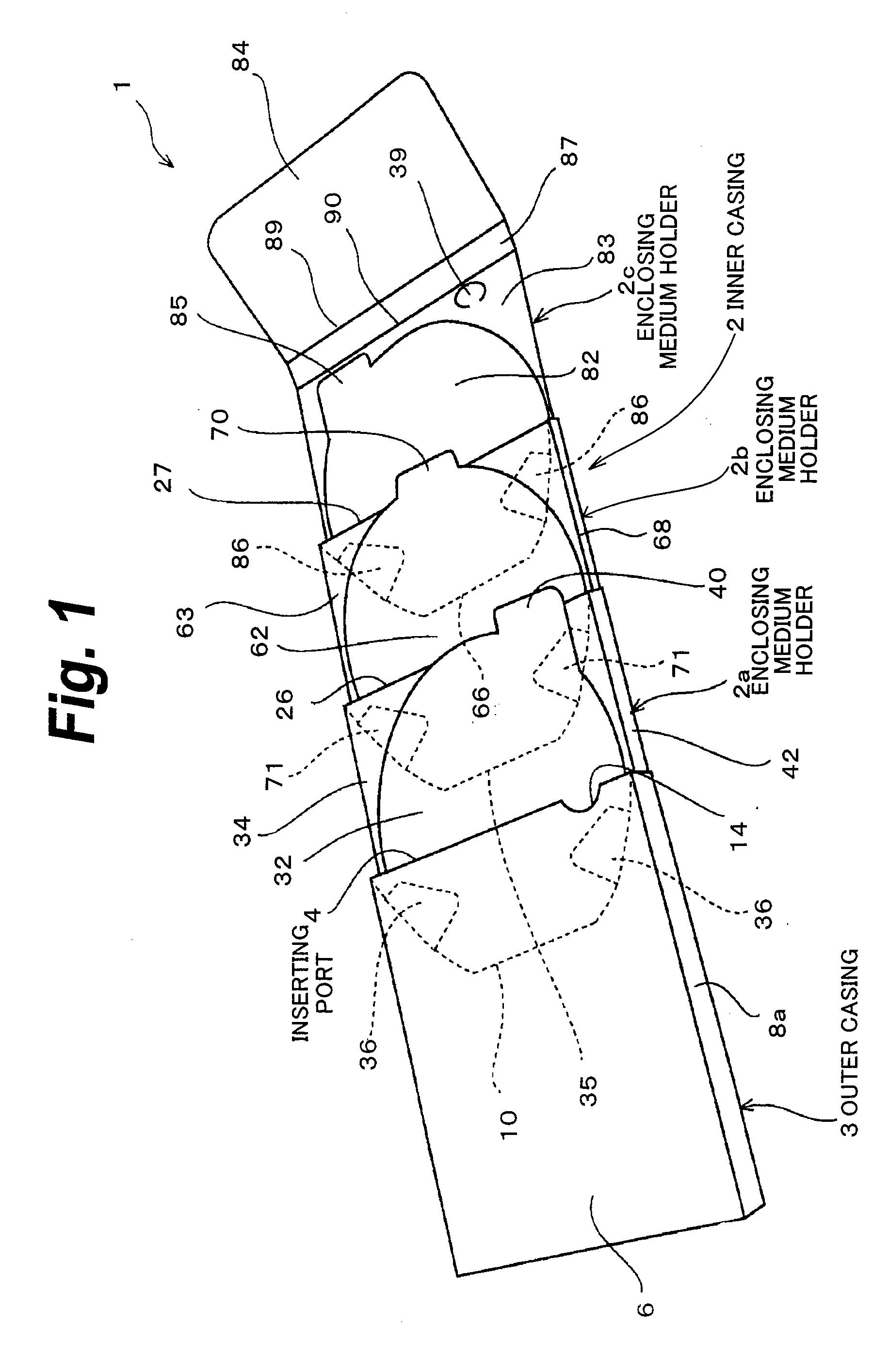

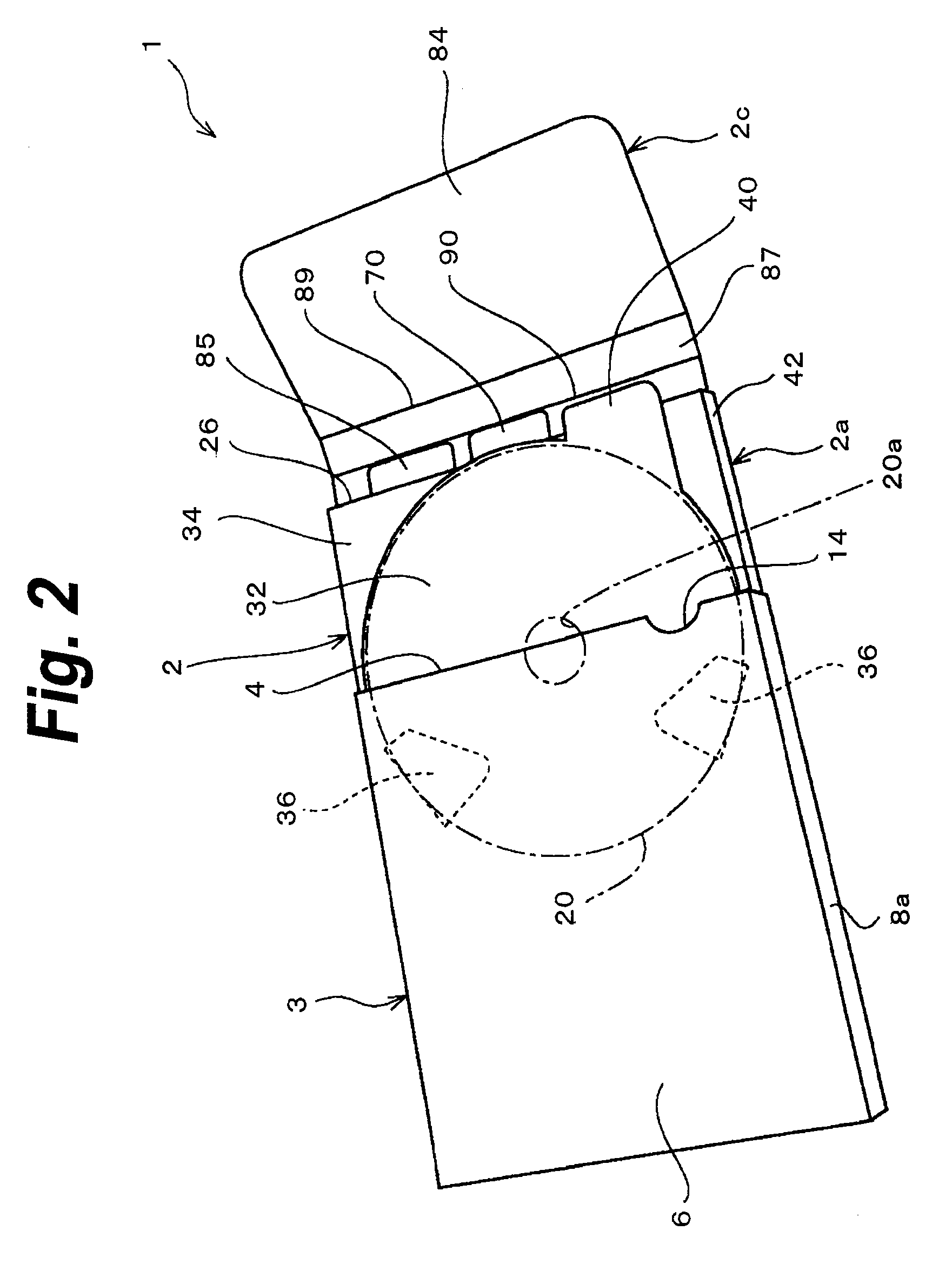

[0003] To solve the above problem, an enclosing casing of the invention is constructed by a combination of an outer casing having an inserting port in one side portion and an inner casing which is inserted and ejected into / from the outer casing through the inserting port, wherein the inner casing is constructed by enclosing medium holders of a plurality of stages which overlap each other so as to be relatively movable. Any one of the enclosing medium holders of the plurality of stages can be enclosed in the outer casing. It is sufficient that the outer casing has such a shape that the enclosing medium holders of the plurality of stages can be collectively enclosed and carried. Although it may have, for example, a shape like a tray, such a shape as to wrap the whole enclosing medium holder is preferable from a viewpoint of protecting the enclosing medium held in the enclosing medium holder against the dust,

sunlight, and the like. For example, it is preferable to use a box-shape having such an internal volume that all of the enclosing medium holders hold the enclosing media and can be enclosed in the outer casing so as to overlap each other. The enclosing medium is held in the enclosing medium holder, inserted and ejected into / from the outer casing together with the enclosing medium holder, and relatively moved to the other enclosing medium holders. In order to prevent the enclosing medium from falling from the enclosing medium holder at the time of the

insertion / ejection or the relative movement, it is desirable that a restricting portion which can maintain the stable holding of the enclosing medium while restricting a positional deviation of the enclosing medium is provided for the enclosing medium holder. If the positional deviation of the enclosing medium in the enclosing medium holder can be restricted, a rub of the enclosing medium to the enclosing medium holder can be also prevented. The enclosing medium holders of the plurality of stages overlap each other so as to be relatively movable. That is, it is possible to freely develop so as to mutually overlap the enclosing medium holders or reduce the overlap portion. If the enclosing medium holders are pulled out of the outer casing and developed, an overlap area of the enclosing media can be decreased. Thus, the user can see the enclosing media in a lump and recognize a desired one of the plurality of enclosing media at a glance. The enclosing medium locating at a lower stage can be easily taken out since the enclosing medium holder locating at an upper stage and the enclosing medium held therein do not become obstacles. By mutually allowing the enclosing medium holders to overlap each other, plane dimensions can be reduced as compared with those in the developed state. If the enclosing medium holders are enclosed in the outer casing in this state, the plane dimensions of the whole enclosing casing can be decreased. Thus, a storing space can be decreased and when the enclosing casing is carried, it can be easily handled because it has a compact size. Hitherto, the operation in the enclosing casing constructed by the combination of the outer casing and the inner casing is only such an operation that one inner casing is inserted and ejected into / from the outer casing. On the other hand, the invention has such unpredictability and interest that the enclosing medium holders of the plurality of stages constructing the inner casing are relatively moved and causes the user to be interested in it. Each of the outer casing and the inner casing is formed by folding a paper material. It is an essence that the paper material is paper as a main material. The paper material is not limited to a material which is manufactured from vegetable

fiber or other

fiber. Naturally, it is possible to use a paper material which is manufactured by mixing one or more kinds of a mechanical pulp and a

chemical pulp which are manufactured from a conifer or a broad-leaved tree and an wastepaper pulp which is obtained by recycling newspaper, wastepaper, and the like. Synthetic paper manufactured by using a synthetic high molecular substance may be used. It is also possible to use any one of a corrugated

cardboard, a material in which one or both of the surfaces are made of nonwoven fabrics, a material in which one or both of the surfaces are coated with an electrostatic inhibitor, and a material in which a

thermoplastic resin layer has been laminated onto one or both of the surfaces. When the enclosing medium holders of a plurality of stages are inserted and ejected into / from the outer casing, if they are reciprocatively moved in almost the same direction, each enclosing medium holder can be individually inserted and ejected into / from the outer casing. Thus, there is no need to pull out all of the enclosing medium holders from the outer casing and develop them and a space necessary to pull out the enclosing medium holders from the outer casing can be reduced. At the time of the relative movement of the enclosing medium holders, if the relative movement is continued in such a direction as to decrease an overlap amount of both of the holders, they are separated and there is a fear of dropout or loss. Therefore, if retaining portions which are mutually hooked so as to

restrict the relative movement in the separating direction of them are provided in the portions where the enclosing medium holders overlap each other, the separation of the enclosing medium holders can be prevented. Since the retaining portions are mutually hooked, in association with the pulling-out operation of a certain enclosing medium holder, a traction operation which can also pull out the other enclosing medium holder is also obtained. In the portions where the outer casing and the enclosing medium holder overlap, retaining portions which are hooked so as to prevent the separation of them may be also provided. If a lid portion which closes the inserting port of the outer casing in the state where all of the enclosing medium holders have been enclosed in the outer casing is provided for the enclosing medium holder or the outer casing, a fly-out of the enclosing medium from the inserting port and the entering of the dust or

moisture from the inserting port can be prevented. The number of parts can be reduced and the loss of the media can be also prevented as compared with the case where the lid portion is provided as a separate member. Particularly, if the lid portion is provided for the enclosing medium holder instead of the outer casing, since the opening / closing operation of the lid portion can be performed simultaneously with the inserting / ejecting operation of the enclosing medium holder into / from the outer casing, the high

usability is obtained. Further, if the lid portion is provided for the enclosing medium holder of the lowest stage and folded so as to wrap the enclosing medium holder of the upper stage side and a

front edge portion of the lid portion is inserted into the inserting port, all of the enclosing medium holders can be shielded from the outside of the outer casing. When the enclosing medium holders are pulled out of the outer casing, since the lid portion is developed at the lowest stage, the other enclosing medium holders are not covered nor hidden. If enclosing medium holders of a plurality of stages are enclosed so as to overlap each other in a telescopic form in which the smaller holders are sequentially fitted into the larger holders, larger mutual contact portions of the enclosing medium holders than those of, for example, tray-shaped enclosing medium holders can be assured and a guide operation adapted to enable the relative movement in a desired direction to be certainly executed is obtained. Particularly, if a gap larger than a thickness of enclosing medium which is held in the inside enclosing medium holder is assured between the outside enclosing medium holder and the inside enclosing medium holder which is fitted therein, a pressing force does not act on the enclosing medium held in the inside enclosing medium holder from the outside enclosing medium holder, so that a damage or deformation of the enclosing medium can be prevented. At the time of the relative movement of the enclosing medium holders, the rub with the outside enclosing medium holder can be prevented and it is possible to prevent the enclosing medium from being scratched. In the case where a tab is provided for an edge portion of the enclosing medium holder which faces the inserting port in the state where the enclosing medium holder has been enclosed in the outer casing, the tab can be made to function as a knob for enabling the enclosing medium holder to be easily pulled out. Further, if the contents of the enclosing medium are displayed on the tab, the tab can be also made to function as a

label for identifying the enclosing medium. According to the enclosing casing of the invention, since the inner casing is constructed by enclosing medium holders of a plurality of stages which overlap each other so as to be relatively movable, the overlapped enclosing medium holders can be shifted and the enclosing media held in the respective enclosing medium holders can be seen in a lump. Even the enclosing medium locating at the lower stage can be easily taken out since the enclosing medium holder at the upper stage and the enclosing media held therein do not become obstacles. Thus, the

usability of the user can be improved.

Login to View More

Login to View More  Login to View More

Login to View More