Array substrate, display panel and preparation method of array substrate

A technology of array substrates and substrate substrates, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as AMOLED yield decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

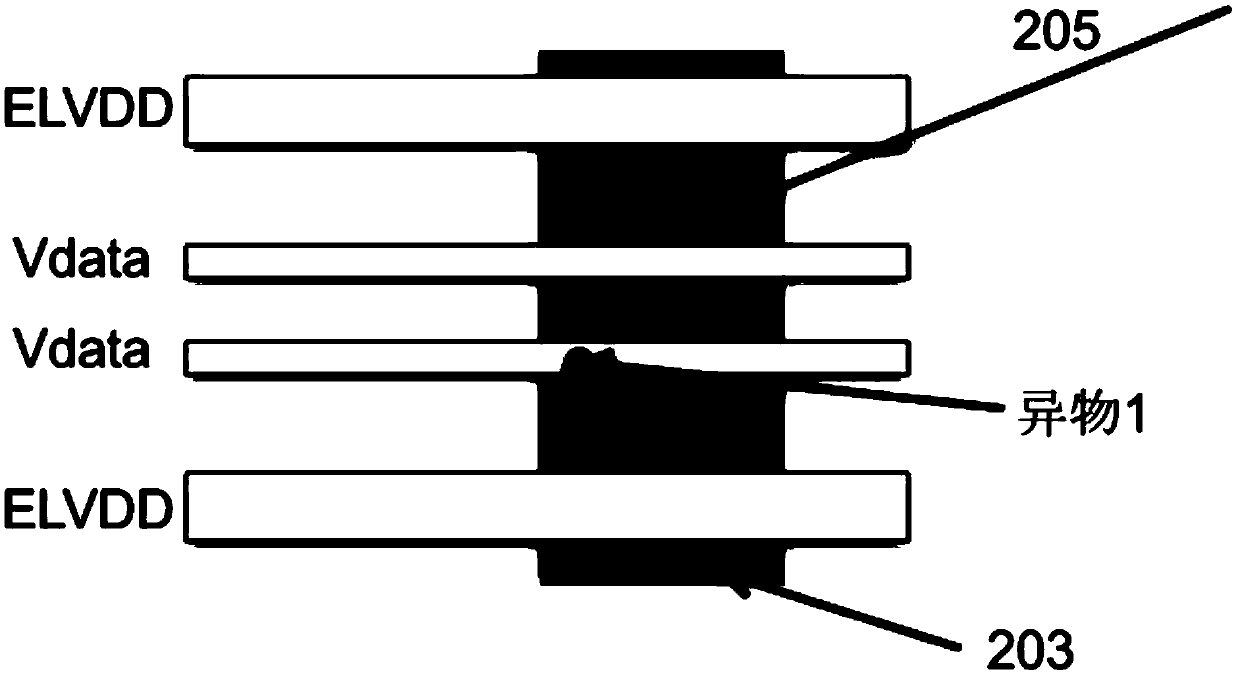

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

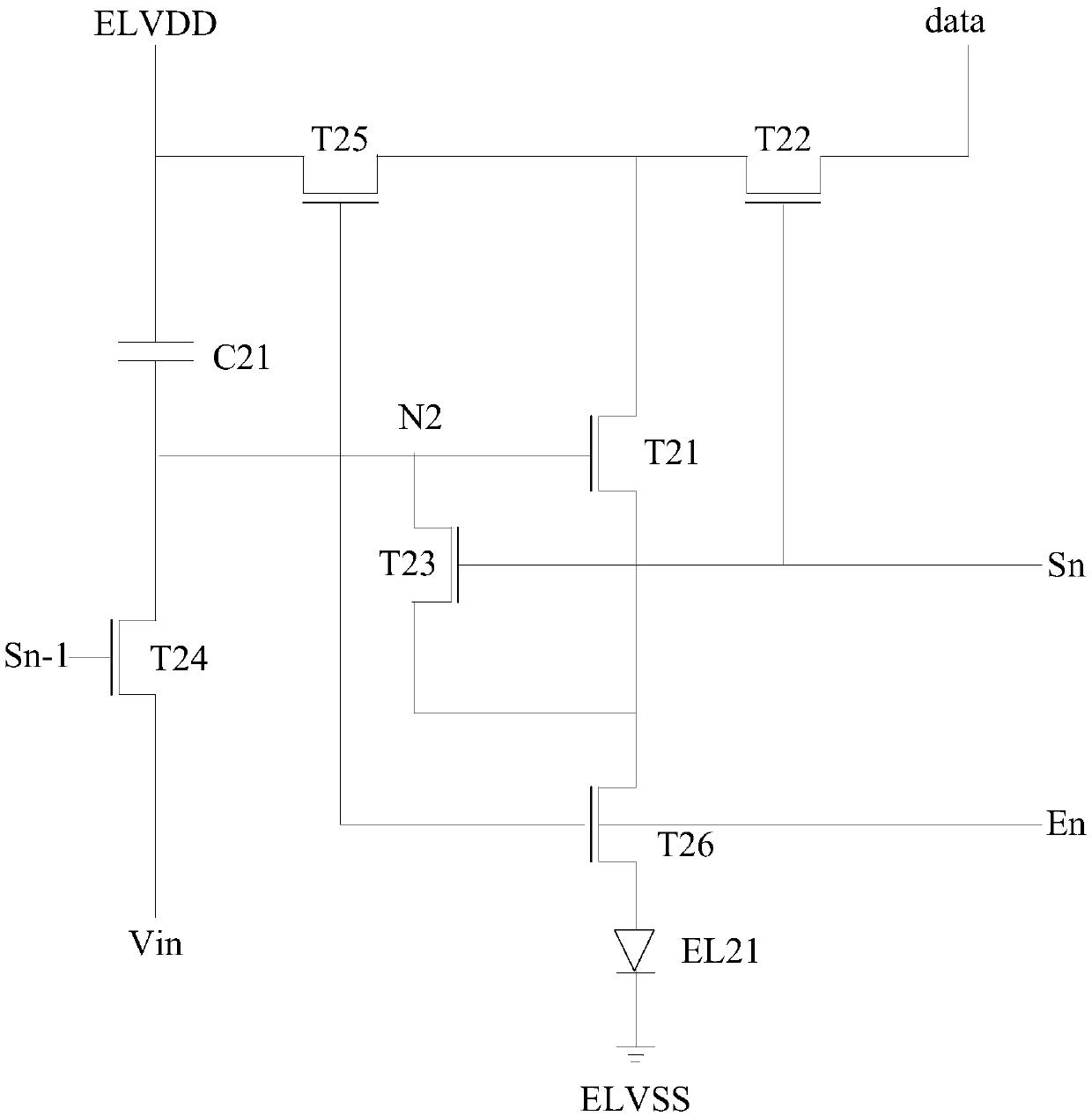

[0032] In the prior art, what AMOLED adopts is a thin film transistor (Thin Film Transistor, TFT) array, and polysilicon TFTs such as CMOS, PMOS, NMOS are prepared on the glass substrate first, and the light-emitting layer is prepared on the TFT, and the driving circuit is used to provide Controlled current to drive OLED, and continue to provide current after driving to ensure that each light-emitting pixel emits light continuously. The production process of AMOLED mainly includes: the production process of TFT and the production process of OLED; among them, the production process of TFT is mainly used to produce OLED drive circuit, TFT circuit is prepared on glass substrate; OLED production process is used to produce OLED pixels that emit light, which is mainly realized by evaporation.

[0033] TFT is divided into polysilicon and amorphous silicon. Among them, low temperature polysilicon (LTPS) is widely used due to its low temperature formation, large area, good space selecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com