Device and method for hob peeling internally geared wheels and related peeling wheel

A technology for planing and wheel blanks, which is applied to gear tooth manufacturing devices, gear cutting tools, and components with teeth, etc., and can solve problems such as reducing cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

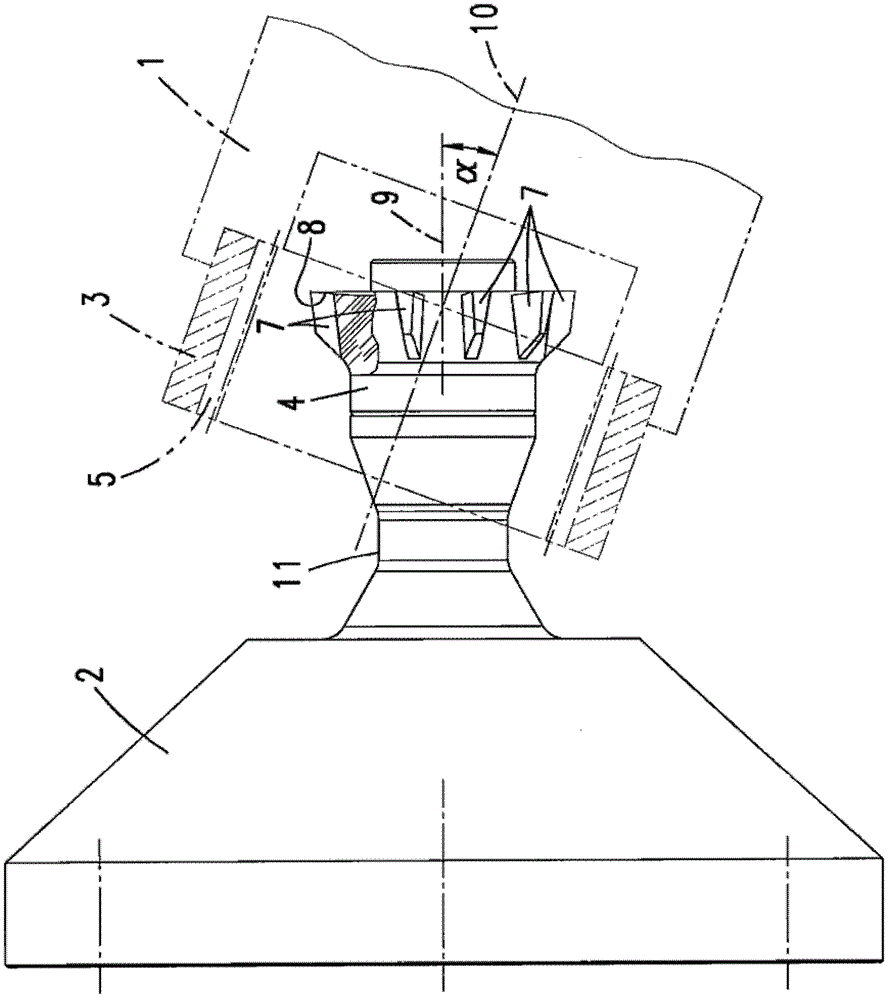

[0015] exist figure 1 In this case, the teeth 7 of the planing wheel 4 are in engagement with the teeth 5 of the wheel blank 3 . Here, the skiving wheel 4 has its deepest axial penetration position. The tool spindle 2 only needs to be reduced slightly in the neck area 11 in order to avoid a collision with the edge of the wheel blank 3 .

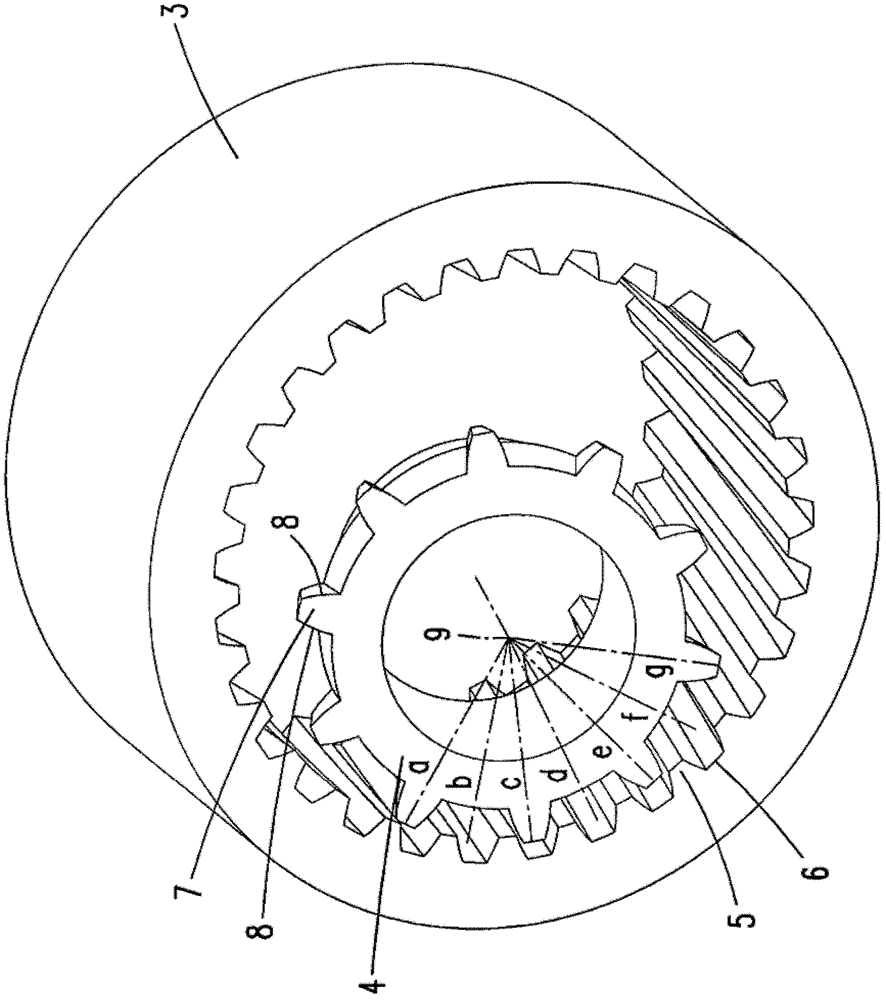

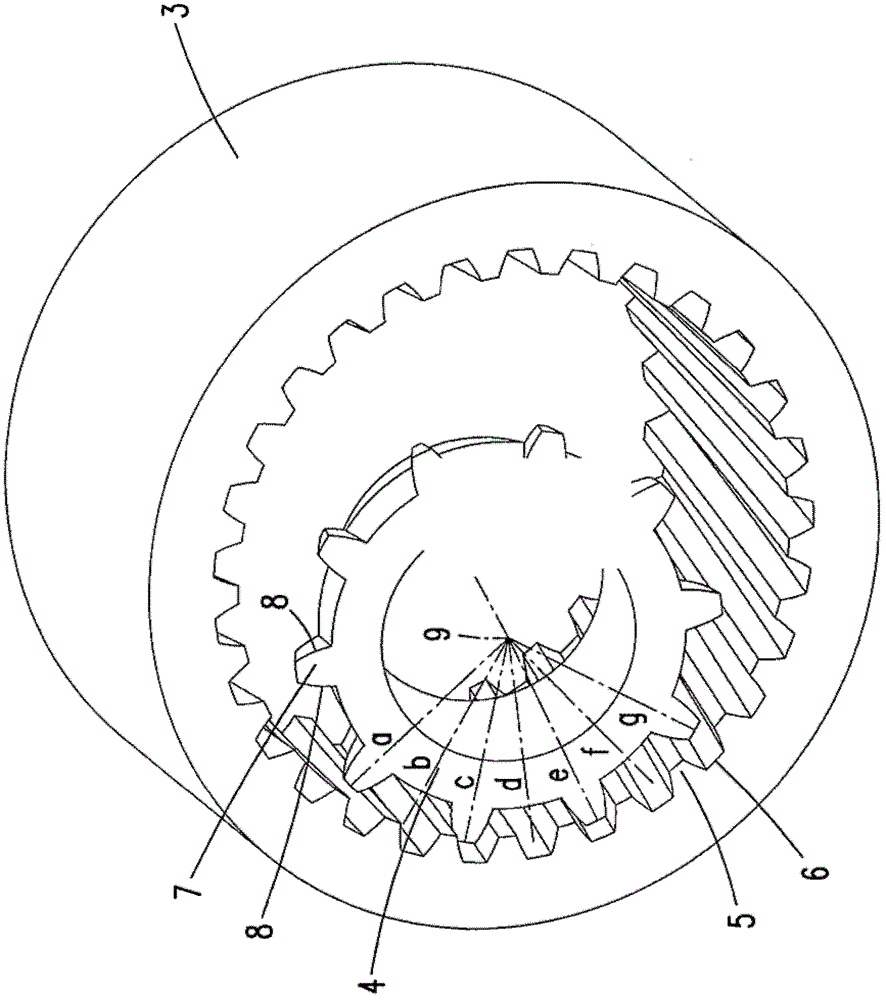

[0016] Depend on figure 2 with 3 It can be seen that the skiving teeth 7 of the skiving wheel 4 always engage in the tooth gap 6 between the two teeth 5 of the wheel blank 3 . exist figure 2 In the position shown, the teeth 7 of the skiving wheel 4 in positions c and e are in the engaged position. exist image 3 , the skiving tooth 7 arranged at position e is located in the deepest engagement position in the tooth gap 6 of the wheel blank 3 . In contrast to the prior art, the number of simultaneously engaged teeth 7 , 5 is reduced.

[0017] Although each tooth gap 6 is only machined every second revolution of the wheel blank 3 , a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com