A method for operating a valve

A technology of valve operation and components, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve problems such as inconvenient and slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

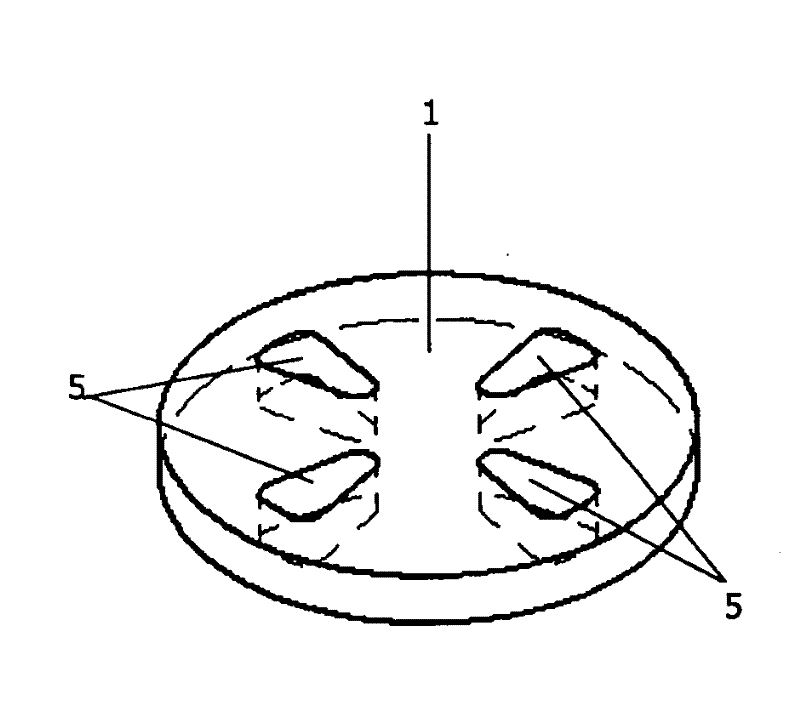

[0041] Figure 1a A first valve part 1 for a valve suitable for carrying out the method according to an embodiment of the invention is shown. The first valve member 1 is in the form of a substantially disc, and it has four openings 2, each of substantially circular cross-section, formed therein as a trough-going bore extending through the disc .

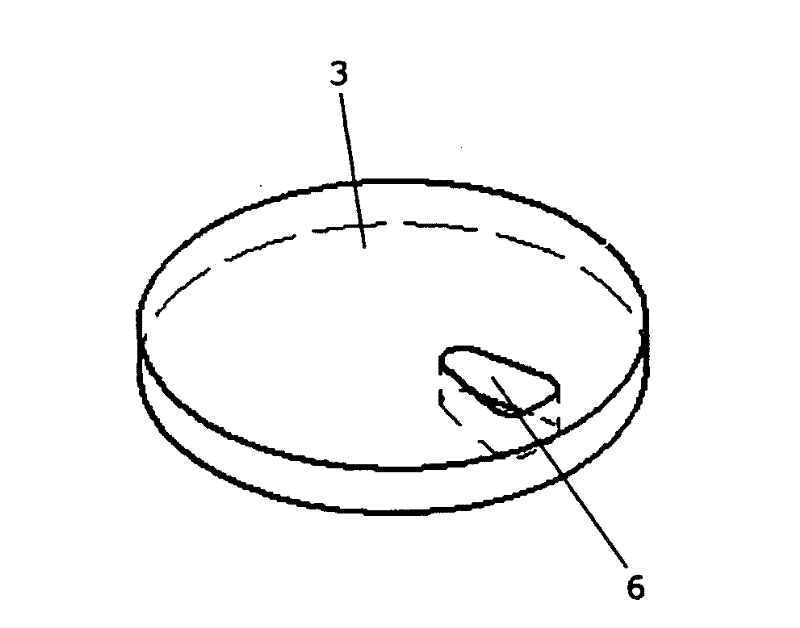

[0042] Figure 1b A second valve part 3 for a valve suitable for carrying out the method according to an embodiment of the invention is shown. The second valve member 3 is in the form of a substantially circular disk having a diameter substantially equal to Figure 1a The diameter of the first valve part 1. therefore, Figure 1a The first valve part 1 and Figure 1b The second valve part 3 is adapted to form the part of the same valve and cooperates in defining the opening of the valve. This will be referenced below Figure 2a-2f is described in more detail.

[0043] The second valve part 3 is provided with an opening 4 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com