Whole house conveyance machine

a whole-house conveyancing machine and conveyancing technology, applied in special buildings, transportation and packaging, small buildings, etc., can solve the problems of large dimensional constraints imposed by public road shipping on what can be built in a factory, infringing dimensions, and limiting the use of transportation devices for delivery in the homebuilding industry, so as to facilitate the connection of the machine and ensure structural integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

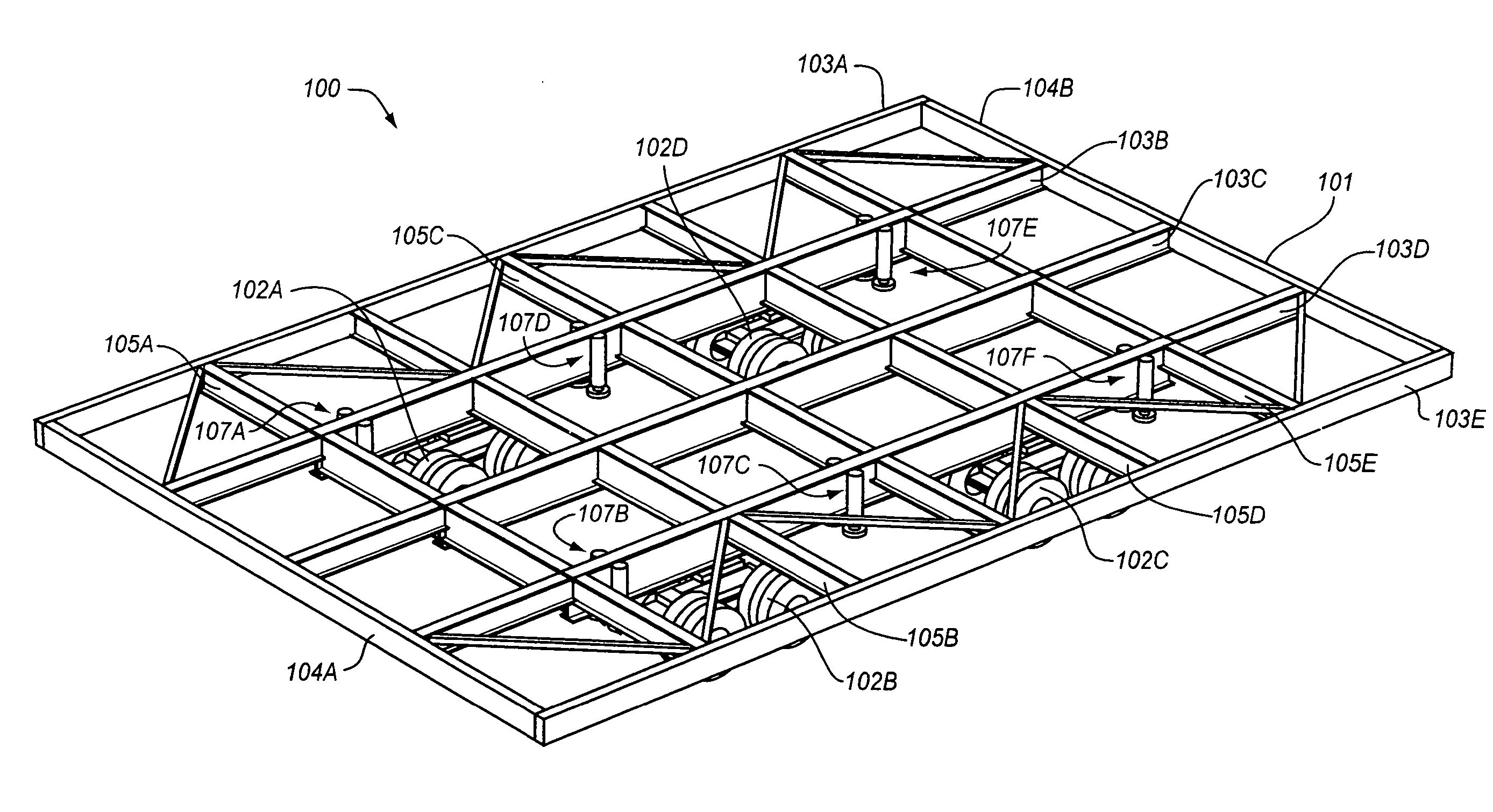

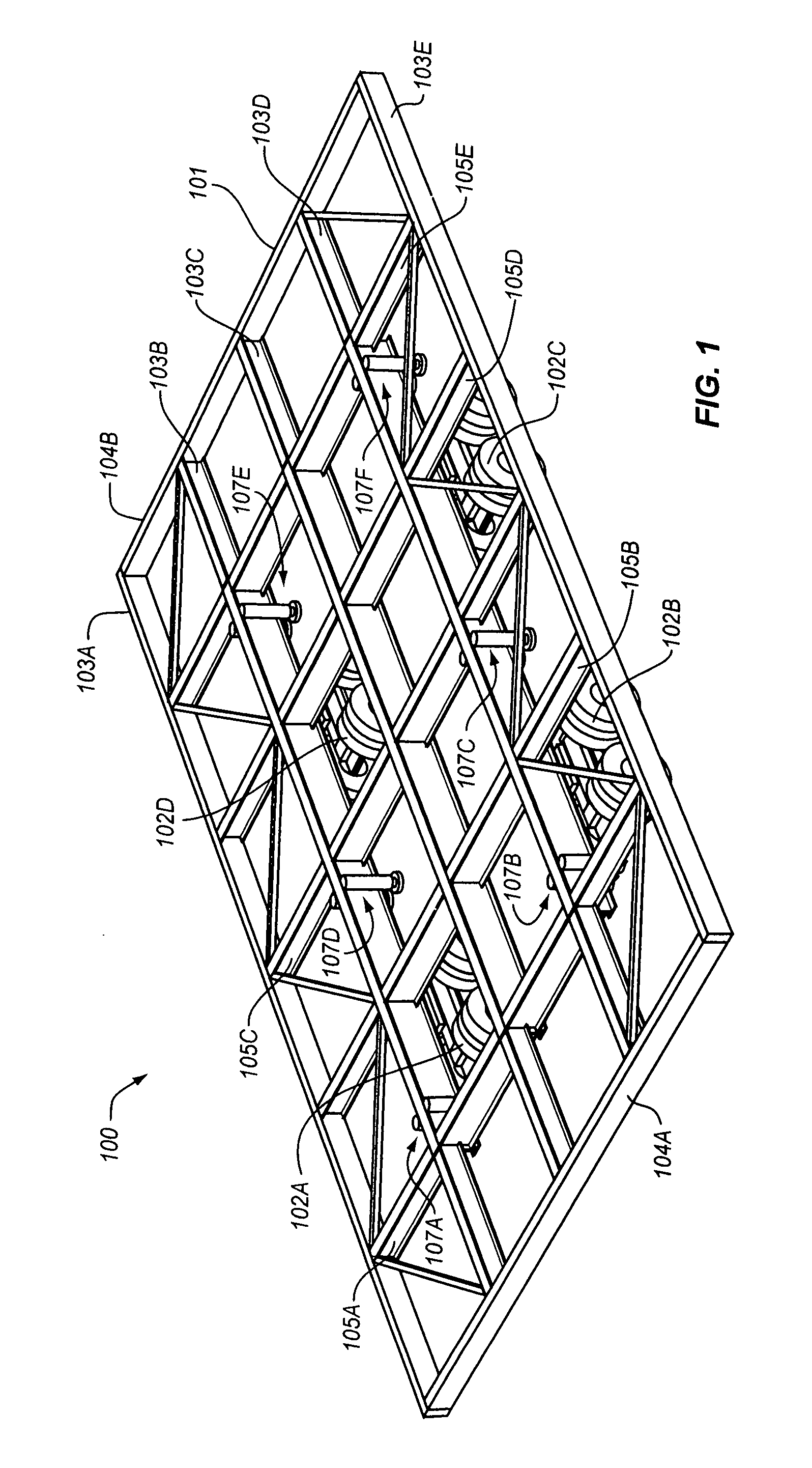

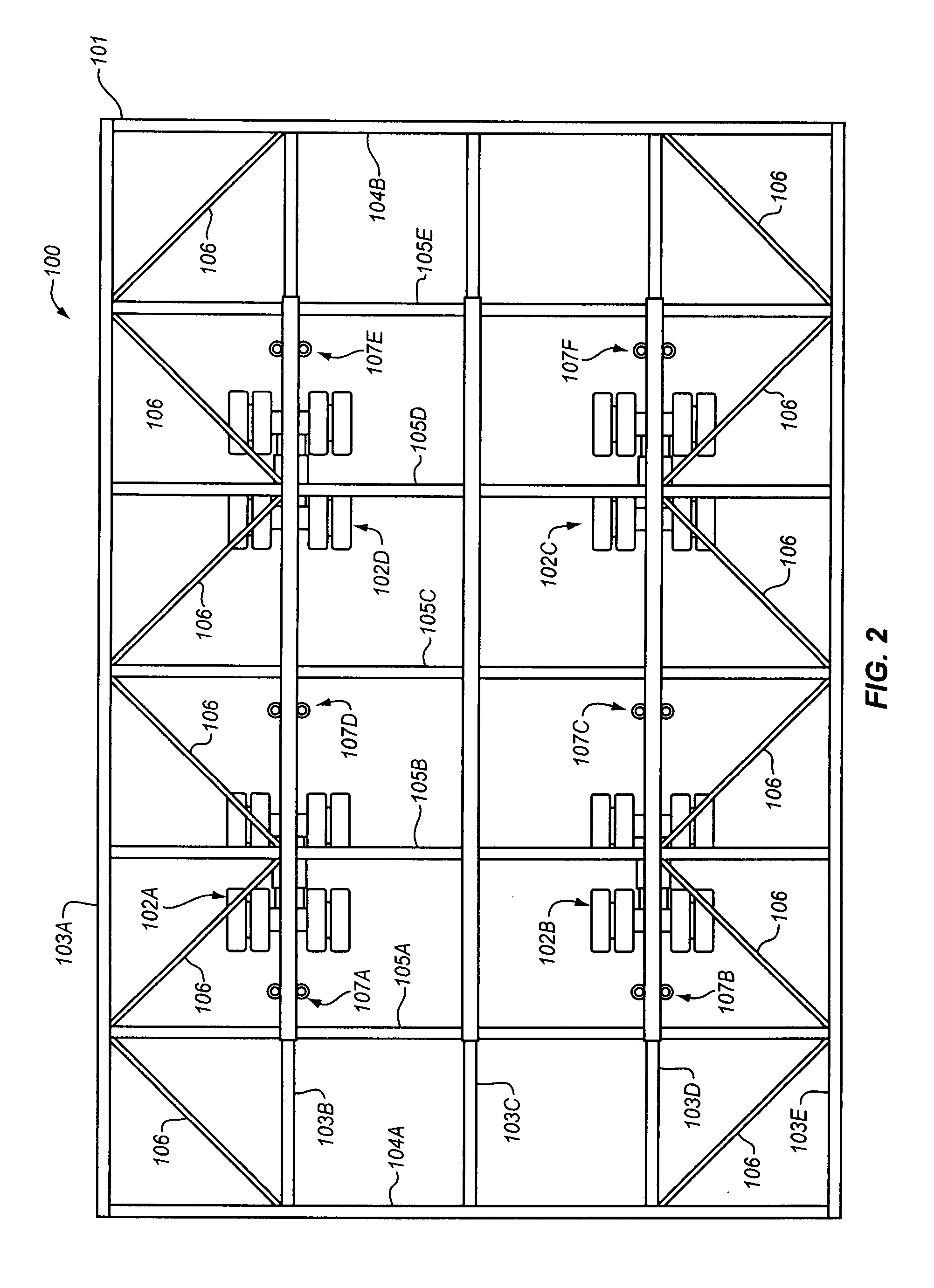

[0016] As described in U.S. Pat. No. 6,253,504, titled “Manufacturing Facility For Production Of Standard Size Dwellings” and U.S. Pat. No. 6,000,192, titled “Method Of Production Of Standard Size Dwellings,” a manufacturing facility can be used to bring standard size home building comprehensively within a controlled environment. The main structure of the standard size home building manufacturing facility is sufficiently tall enough to allow assembly and movement of standard size homes within. Materials and supplies can be efficiently purchased and handled in bulk for use within the standard size home building manufacturing facility. At least two production lines exist within the standard size home building manufacturing facility, each building and assembling different components for the finished housing product. All finishes, cabinets, appliances, roofs, paint, etc., can be installed in the partially completed dwellings prior to houses leaving the production floor. The standard siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com