Method for improving gasification efficiency through the use of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0021] A 15 cm, down-draft stratified gasifier with an integral tar cracking and hydrocarbon reforming lower chamber was used to convert biomass into syngas. In the upper zone the biomass undergoes the decomposition process commencing with devolatization followed by flaming pyrolysis and finally char gasification. In the lower zone a small amount of air is introduced into the syngas such that a small fraction is further oxidized. The heat liberated by this oxidation allows higher order hydrocarbons and tars to be broken down into carbon monoxide and hydrogen. The result of the thermal treatment is that a syngas which is essentially free of tars and higher order hydrocarbons is produced. The air flow to the gasifier was adjusted such that the maximum bed temperature was 850° C. The syngas produced exiting the system was cooled to 40° C. such that any condensable matter is liquefied. The syngas was filtered using a 5 micron polyester filter, passed through a blower and was then used t...

example 2

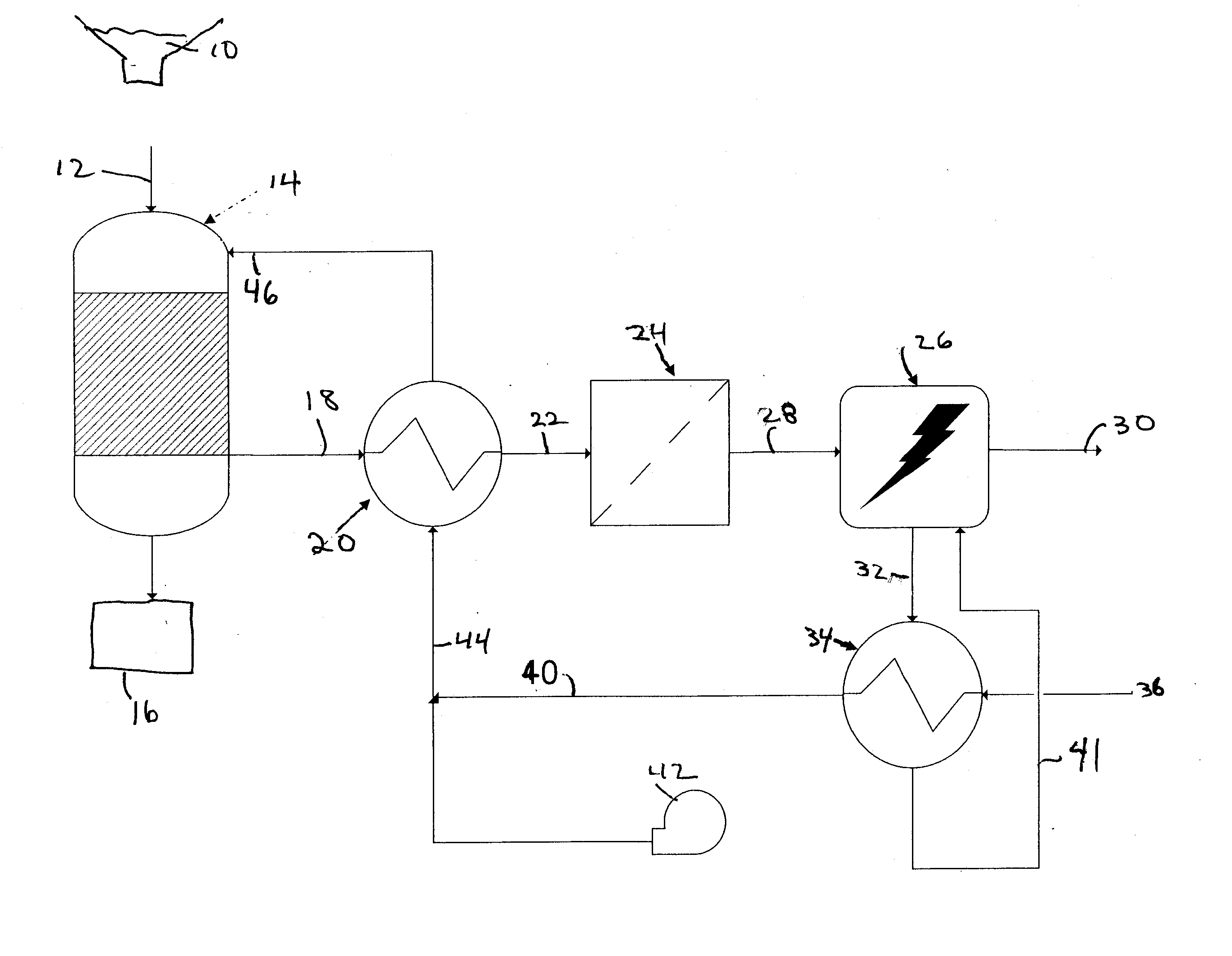

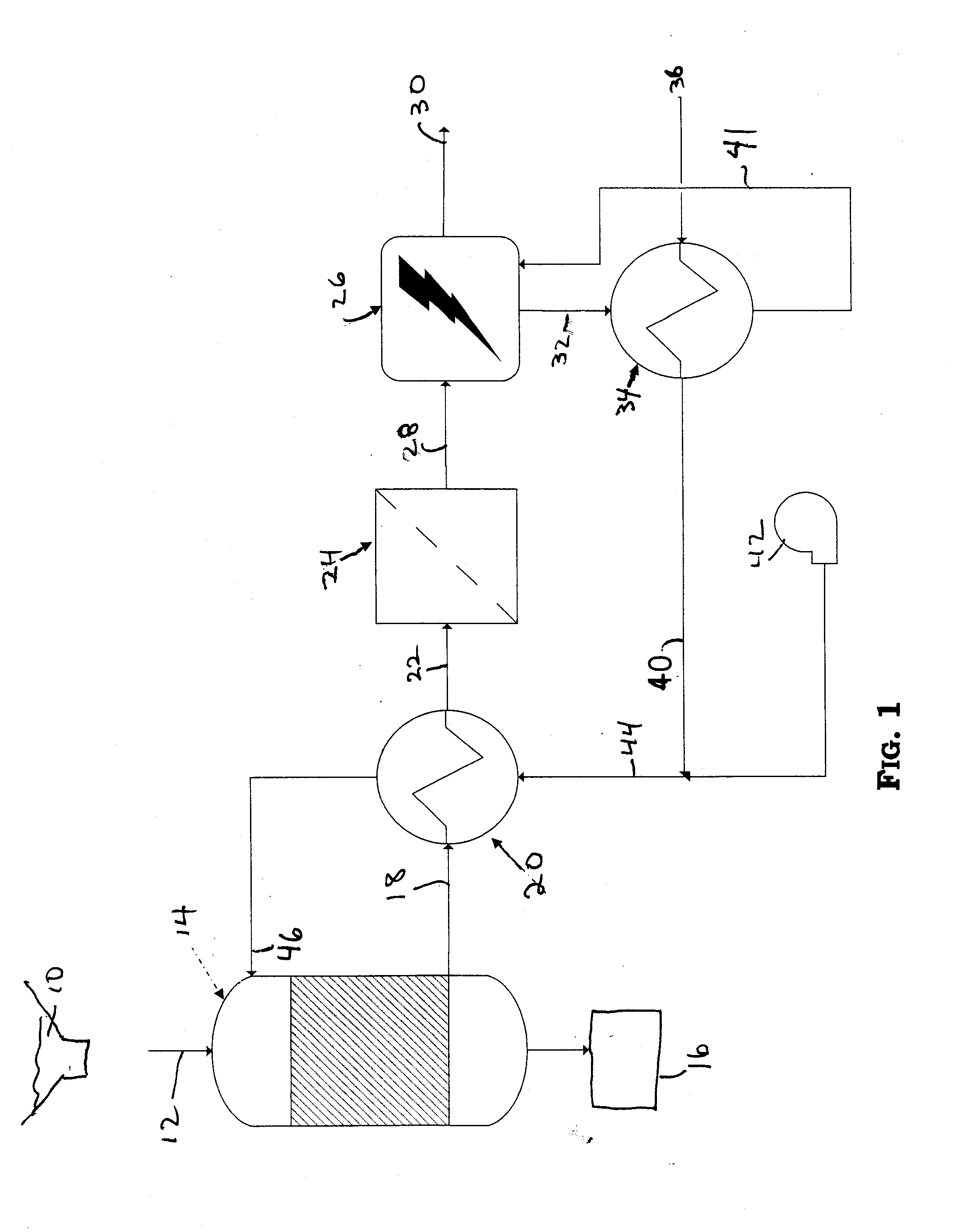

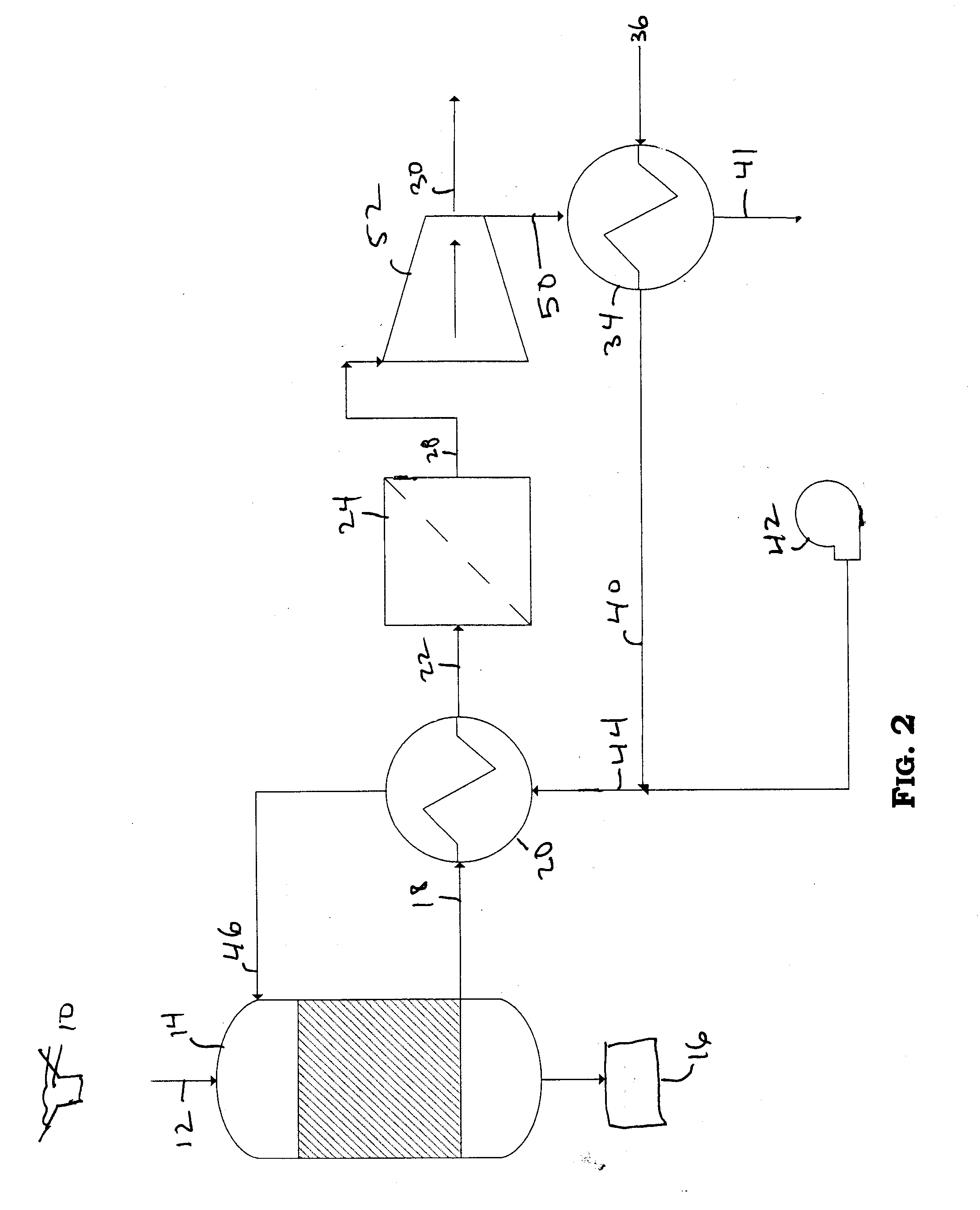

[0024]FIG. 1 illustrates an exemplary, nonlimiting embodiment of a continuous process for recycling waste heat from an electricity generator powered by an internal combustion engine into a gasification system. The result is to both enrich the quality of the gas being produced there and improve the overall thermal efficiency of the gasifier. Biomass 10 is fed via stream 12 into a gasification 14. In the gasifier 14, volatile matter and a good fraction of the fixed carbon is converted into gaseous components. The ash, non-volatiles and any unconverted fixed carbon exit via the ash outlet into a collector 16. The hot syngas stream 18 exits the gasifier 14 and is partially cooled in a booster heat exchanger 20. A number of heat exchangers are suitable for this operation, including, but not limited to, shell and tube, plate duct, welded plate and diffusion bonded plate heat exchangers. It may be advantageous to orientate the exchanger 20 such that the gas stream flows in a vertical plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com