Flooring system and method of installing same

a technology of floor panels, applied in the field of floor coverings, can solve the problems of gaps between floor strips or planks, gaps can become filled with dirt and grime, and expand or shrink,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

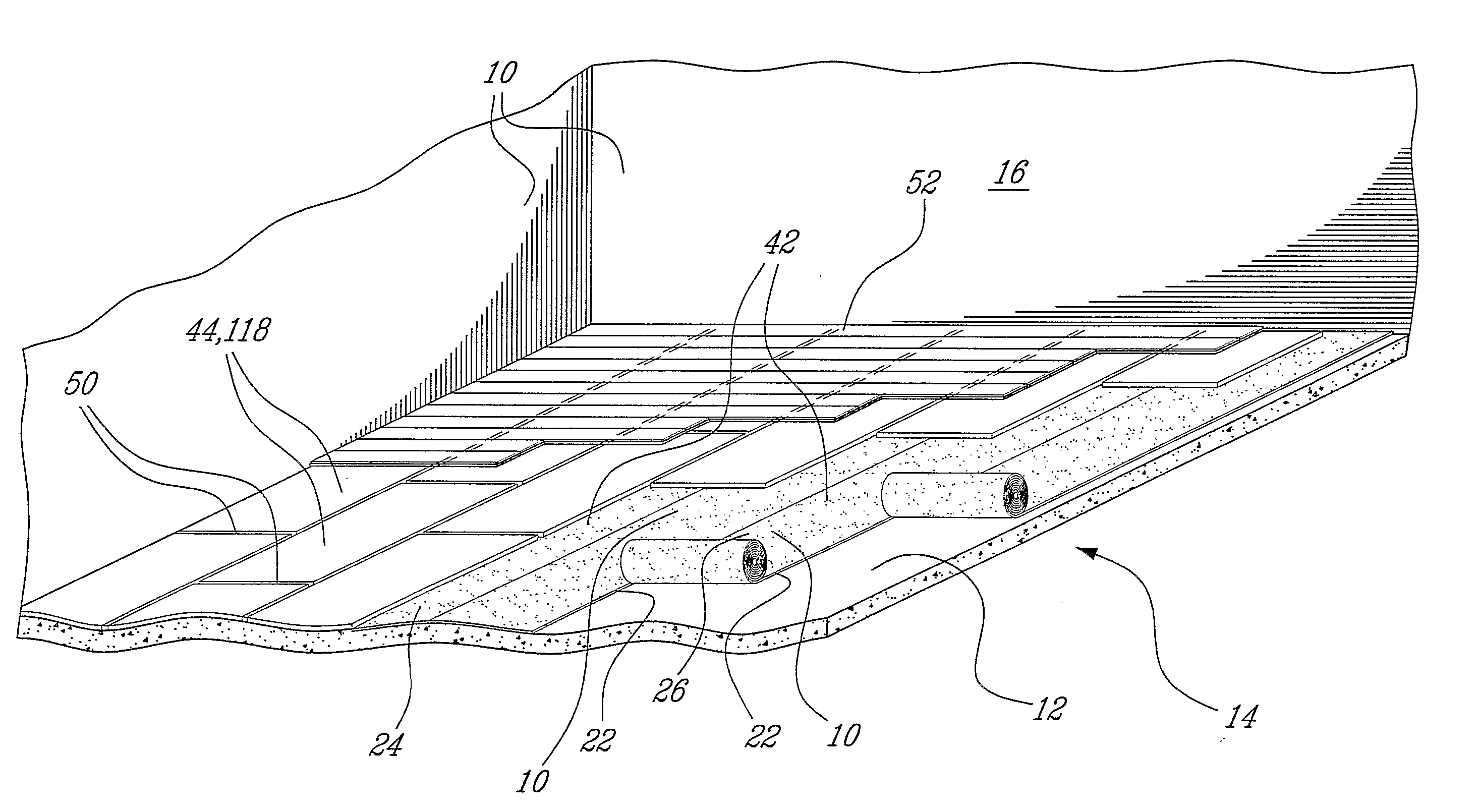

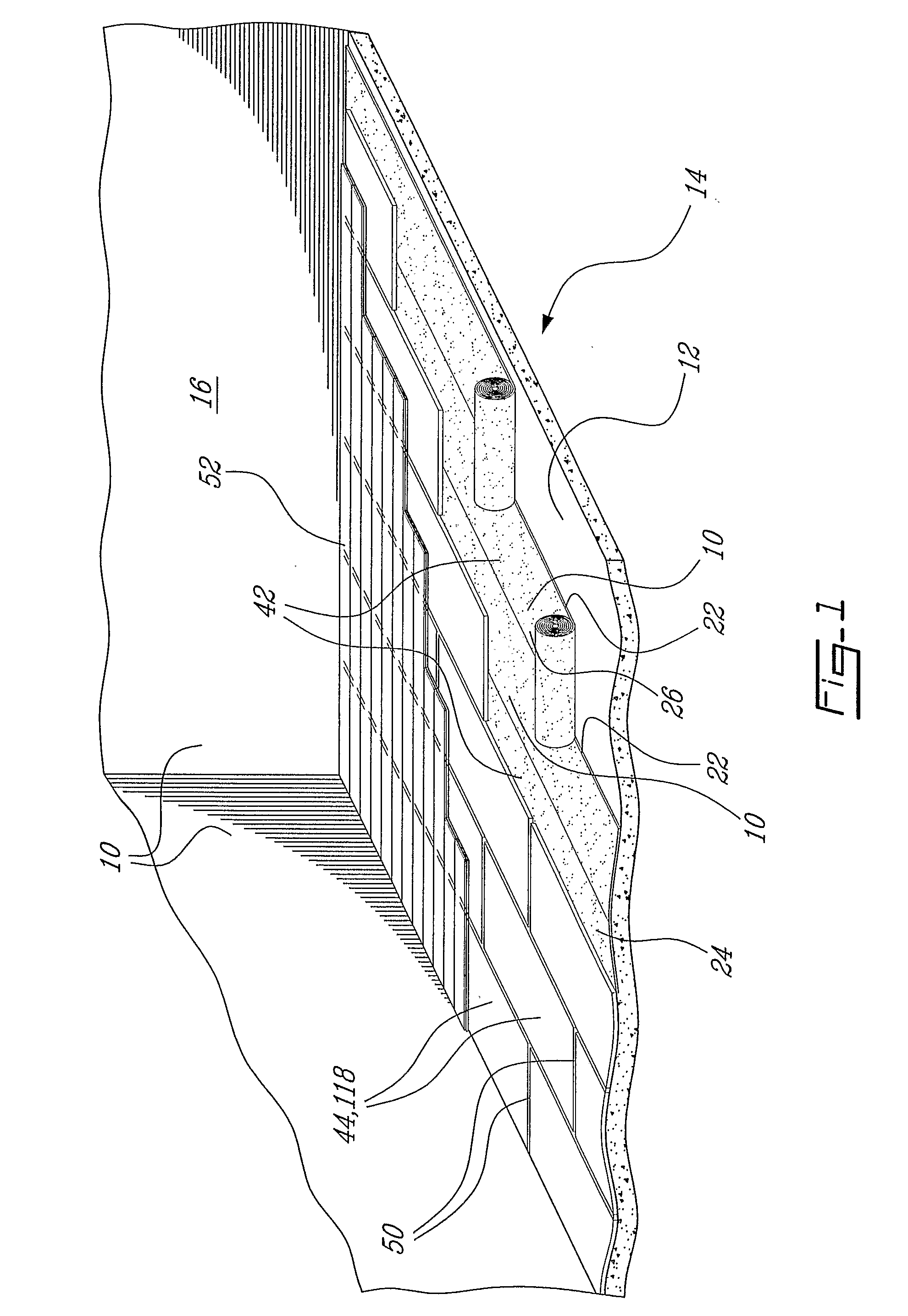

[0027]FIG. 1 is a perspective view of a floor assembly;

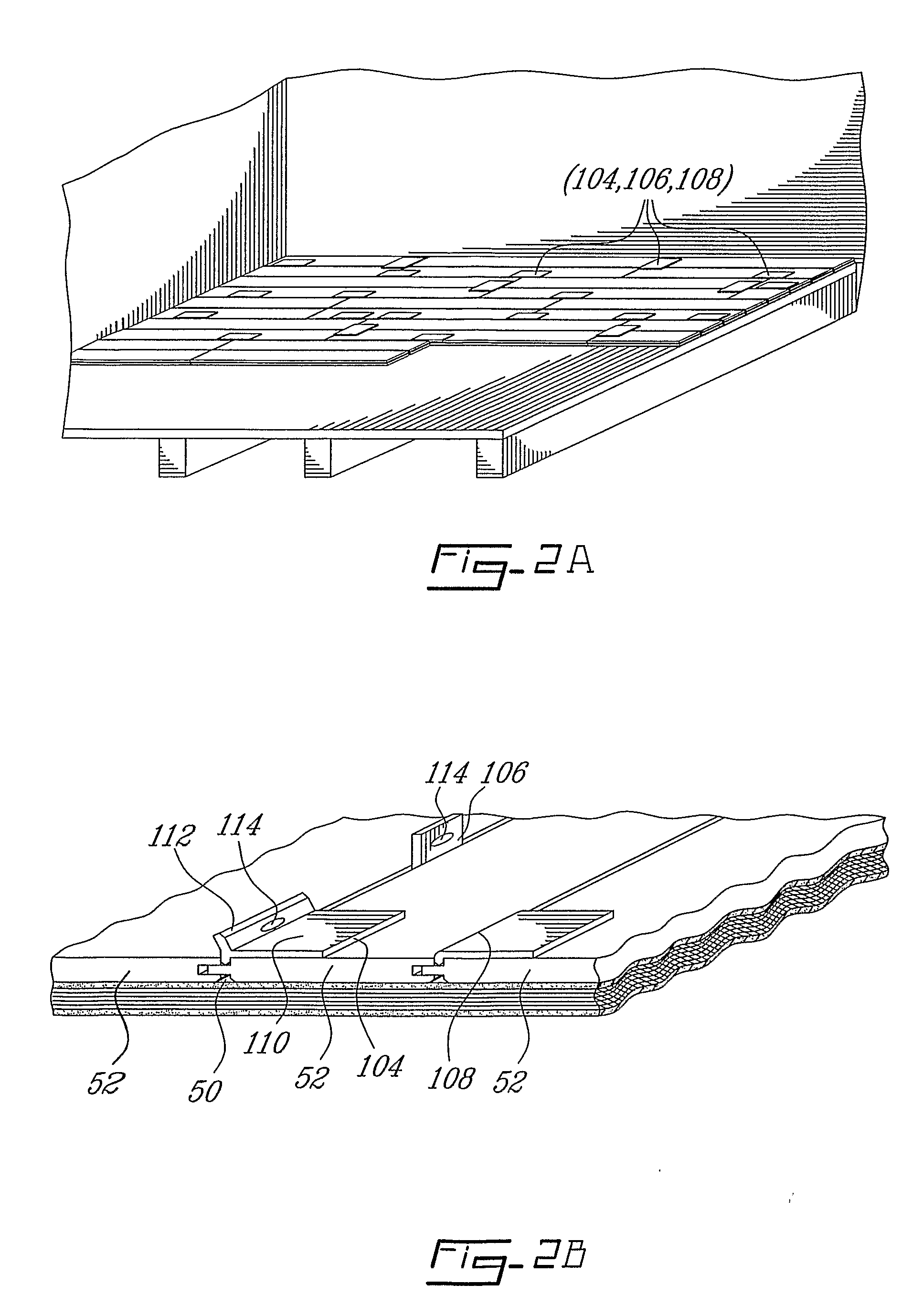

[0028]FIGS. 2ab are perspective views showing the laying of a floor using inter-plank spacing with spacers;

[0029]FIG. 3a is a perspective view of groove and groove profile, hardwood, with two types of splines;

[0030]FIG. 3b is a perspective view of groove and groove profile, multi-ply, with two types of splines;

[0031]FIG. 3c is a perspective view of groove and groove profile, MDF / HDF with two types of splines;

[0032]FIG. 3d is a perspective view of a floating key lock joint and filler;

[0033]FIG. 3e is a perspective view of a floating key lock joint and filler when compressed as a result of plank expansion;

[0034]FIG. 3f is a perspective view of a key lock joint of the prior art;

[0035]FIGS. 4ab are perspective view of prior art regarding pushing out of nailing;

[0036]FIGS. 5ab are perspective view of prior art hardwood floor;

[0037]FIGS. 6ab are perspective view of a multi-groove system;

[0038]FIGS. 7, 8ab illustrate variati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com