Extrusion coating compositions and method

a technology of coating composition and composition, applied in the field of extrusion coating composition, can solve the problems of corrosion of untreated metal substrate, high cost of thick coating, limited thickness, adhesive properties and flexibility of coating applied to metal substrate, etc., and achieve good retortability, good film tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] An extrusion coating composition of the present invention, after application to a metal substrate, provides an extruded coating composition that effectively inhibits the corrosion of metal substrates, such as, but not limited to, aluminum, iron, steel and copper. An extruded coating composition also demonstrates excellent adhesion to the metal substrate, excellent chemical resistance and scratch resistance, and excellent flexibility. An extruded coating composition does not impart a taste to foods or beverages that contact the extruded coating composition.

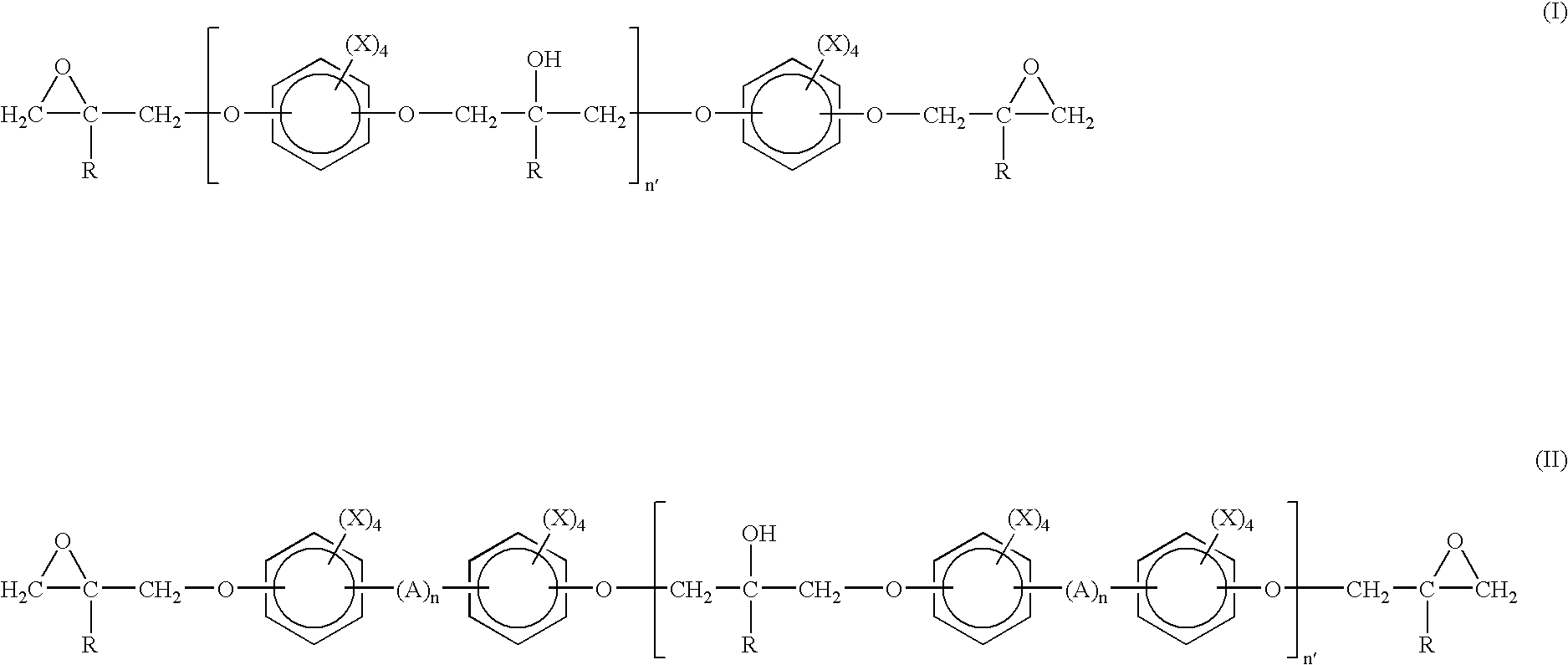

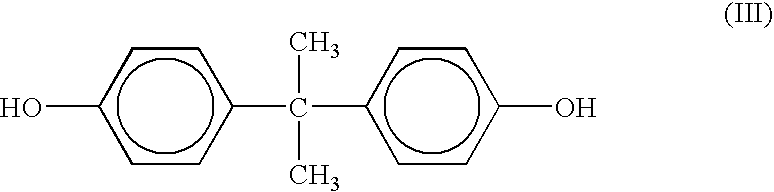

[0029] In general, a present extrusion coating composition comprises: (a) polyester, or a mixture of polyesters, having an Mw of about 10,000 to about 50,000. The extrusion coating composition is a solid and is free of organic solvents. An extrusion coating composition optionally can further include: (b) a modifying resin, such as an epoxy or phenoxy resin having an EEW of about 500 to about 15,000, and / or (c) a filler and / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight average molecular weight | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com