Magnetic disk drive with air bearing surface design for data area expansion

a magnetic disk drive and data area technology, applied in the field of magnetic disk drives, can solve the problems of affecting the flying characteristics of small sliders such as femto sliders, and affecting the flying characteristics of small sliders, so as to suppress the degradation of flying characteristics of magnetic head sliders, and suppress the effect of reducing the recording area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following description is given to illustrate the embodiment of the present invention, and the present invention is not restrictive to the following embodiment. For those skilled in the art, the components of the following embodiment may be easily modified, added, and changed without departing from the scope of the invention. Note that, in the drawings, any identical components share the same reference numeral, and any same description is not made again if appropriate.

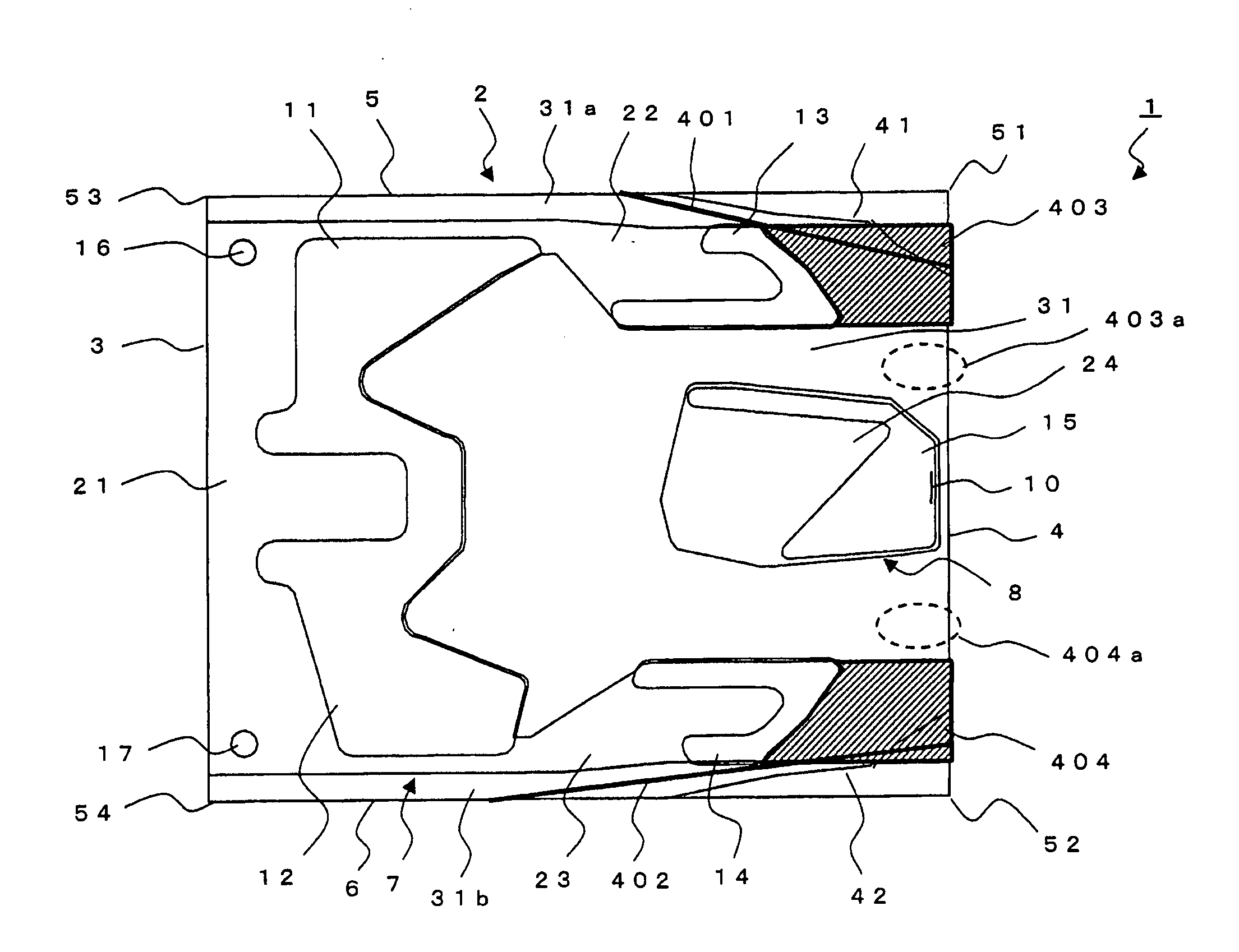

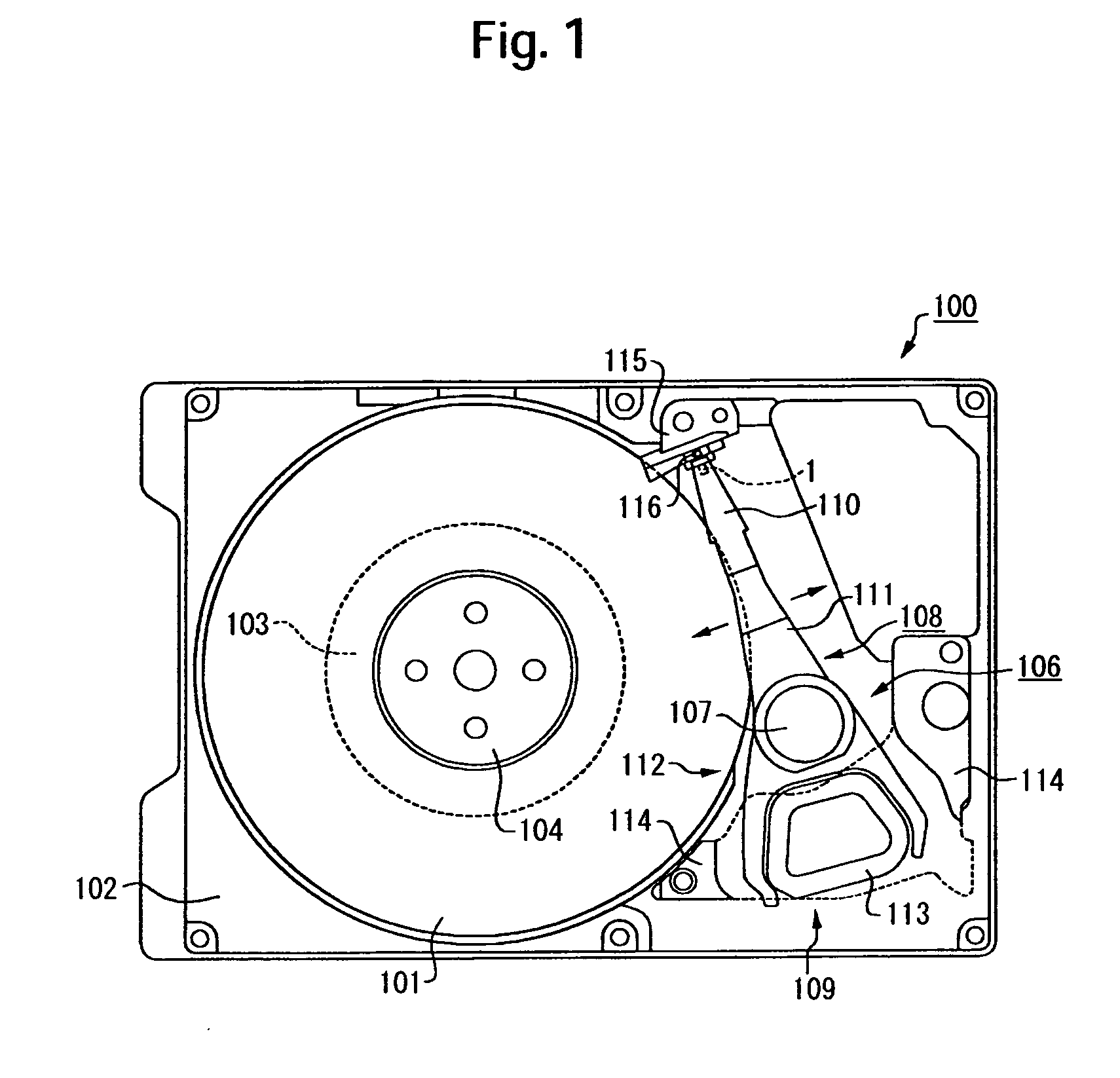

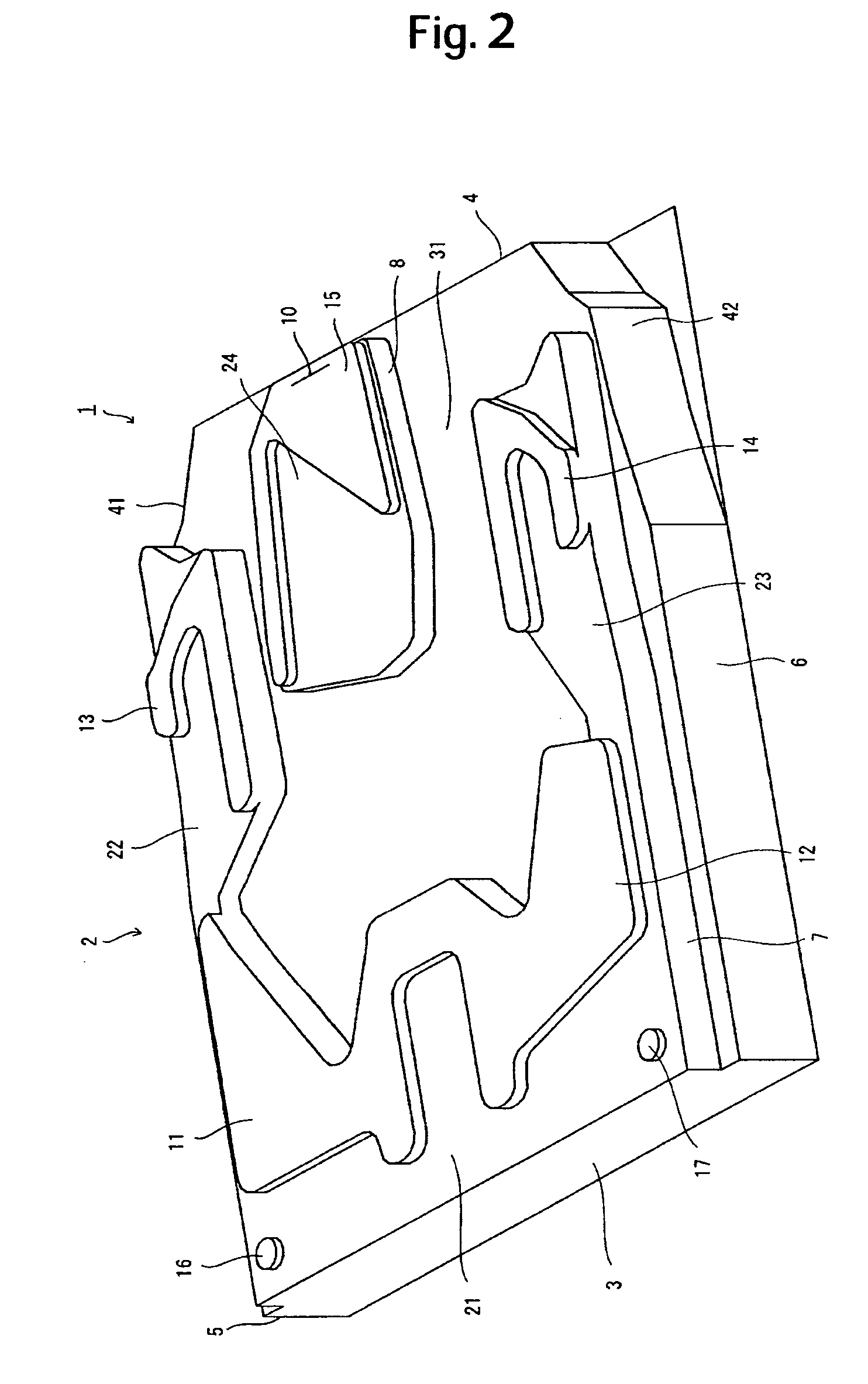

[0037]FIG. 1 is a drawing showing the schematic configuration of a hard disk drive (HDD) 100 according to this embodiment. FIG. 1 shows the state of the HDD 100 when an actuator is disposed at the position when it is stopped (not in operation). A magnetic disk 101 is a medium for recording of data, and is a nonvolatile recording disk that becomes available for recording of data through magnetization of a magnetic layer. A base 102 is fixed to a cover (not shown) that blocks the upper aperture of the base 102...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com