Wafer holder, heater unit having the wafer holder, and wafer prober having the heater unit

a heater unit and wafer technology, applied in the direction of instruments, basic electric elements, measurement devices, etc., can solve the problems of long time between the increase and decrease temperature of the heater, the contact failure between the wafer and the probe pin, and the improvement of the throughput, so as to effectively prevent the contact failure and improve the heat-insulating effect, the effect of less susceptible to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1a

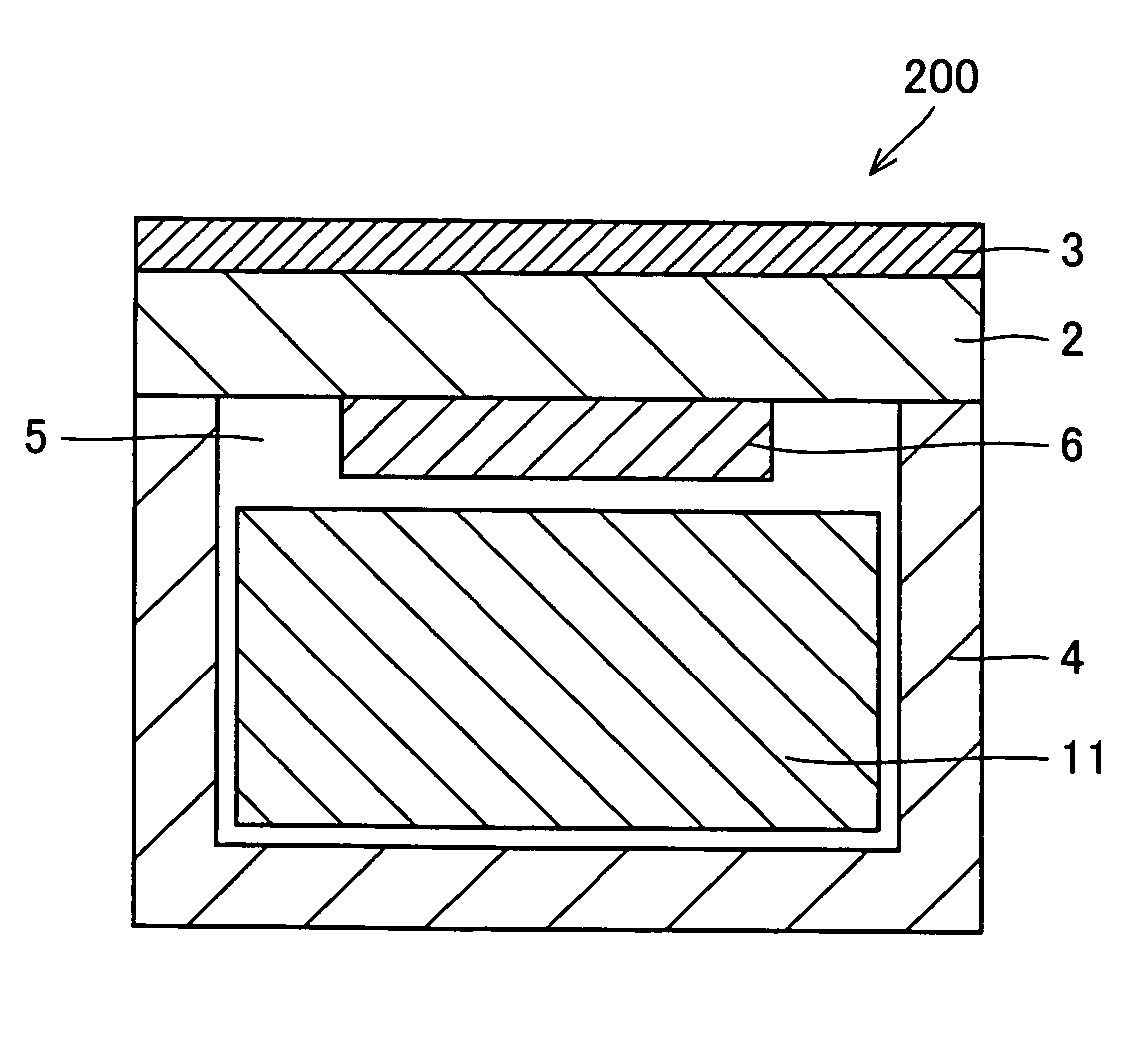

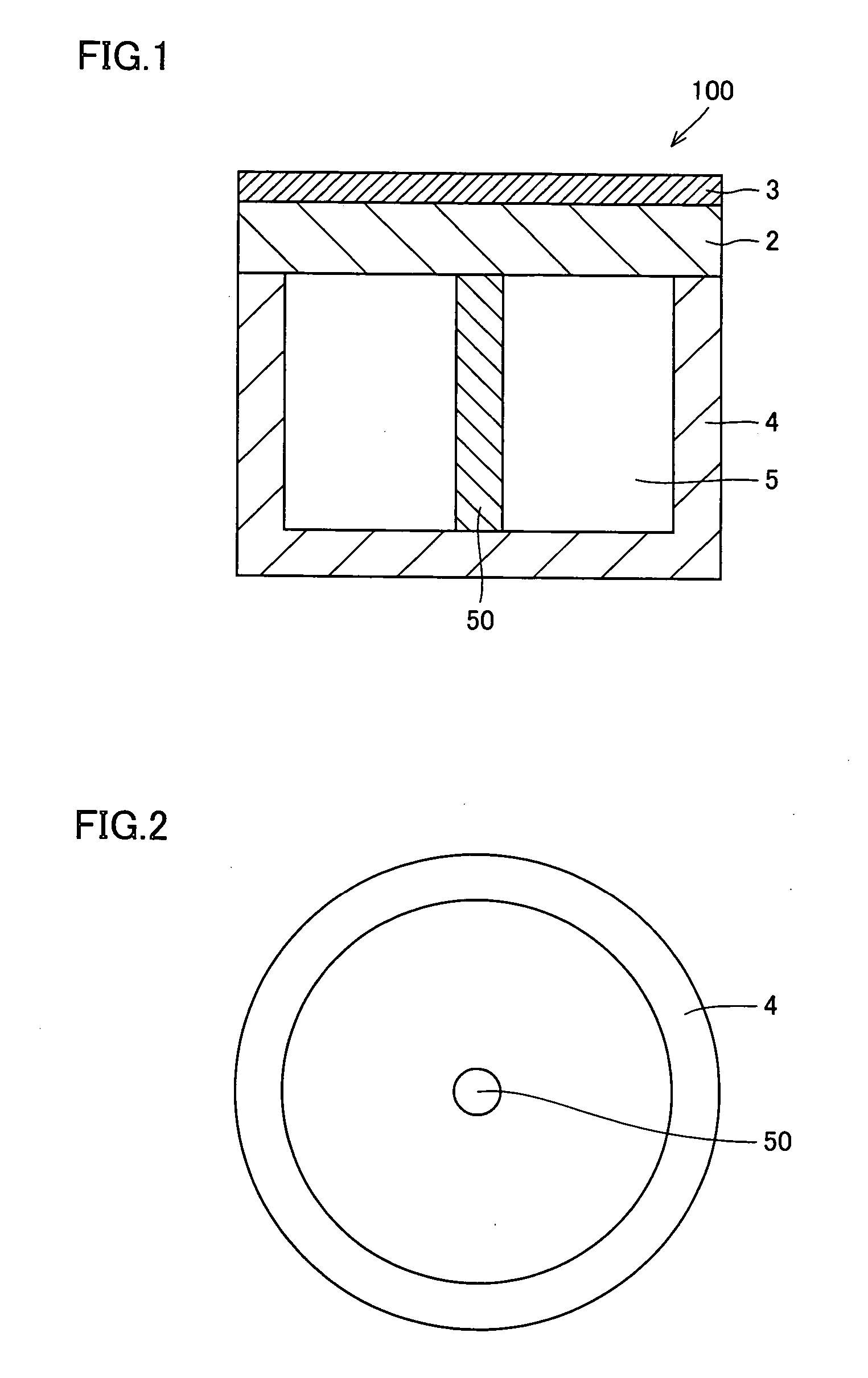

[0118] Wafer holder 100 shown in FIG. 1 was fabricated. An Si—SiC substrate having the diameter of 310 mm and the thickness of 15 mm was prepared. On one surface of the substrate, a concentric trench and through holes for vacuum chucking a wafer were formed, and nickel plating was applied as the chuck top conductive layer 3, to provide a wafer-mounting surface. Thereafter, the wafer-mounting surface was polished and finished to have the overall warp amount of 10 μm and the surface roughness Ra of 0.02 μm, and chuck top 2 was completed.

[0119] Thereafter, a mullite-alumina composite body of a pillar shape having the diameter of 310 mm and thickness of 40 mm was prepared as supporter 4. The surface of supporter 4 in contact with the chuck top and the bottom surface are finished to the flatness of 0.09 mm, and the surface on the side of chuck top 2 was counter-bored to have the inner diameter of 290 mm and the depth of 20 mm, to provide the space for mounting heater body 6 shown in FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com