Air-cooled condenser

a technology of air-cooled condensers and condensers, which is applied in the direction of steam/vapor condensers, stationary conduit assemblies, lighting and heating apparatuses, etc., can solve the problems of large installation height, large substructure, and the inability of air-cooled condensers to achieve uniform distribution, etc., to achieve cost-effective design, large cooling capacity, and small space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

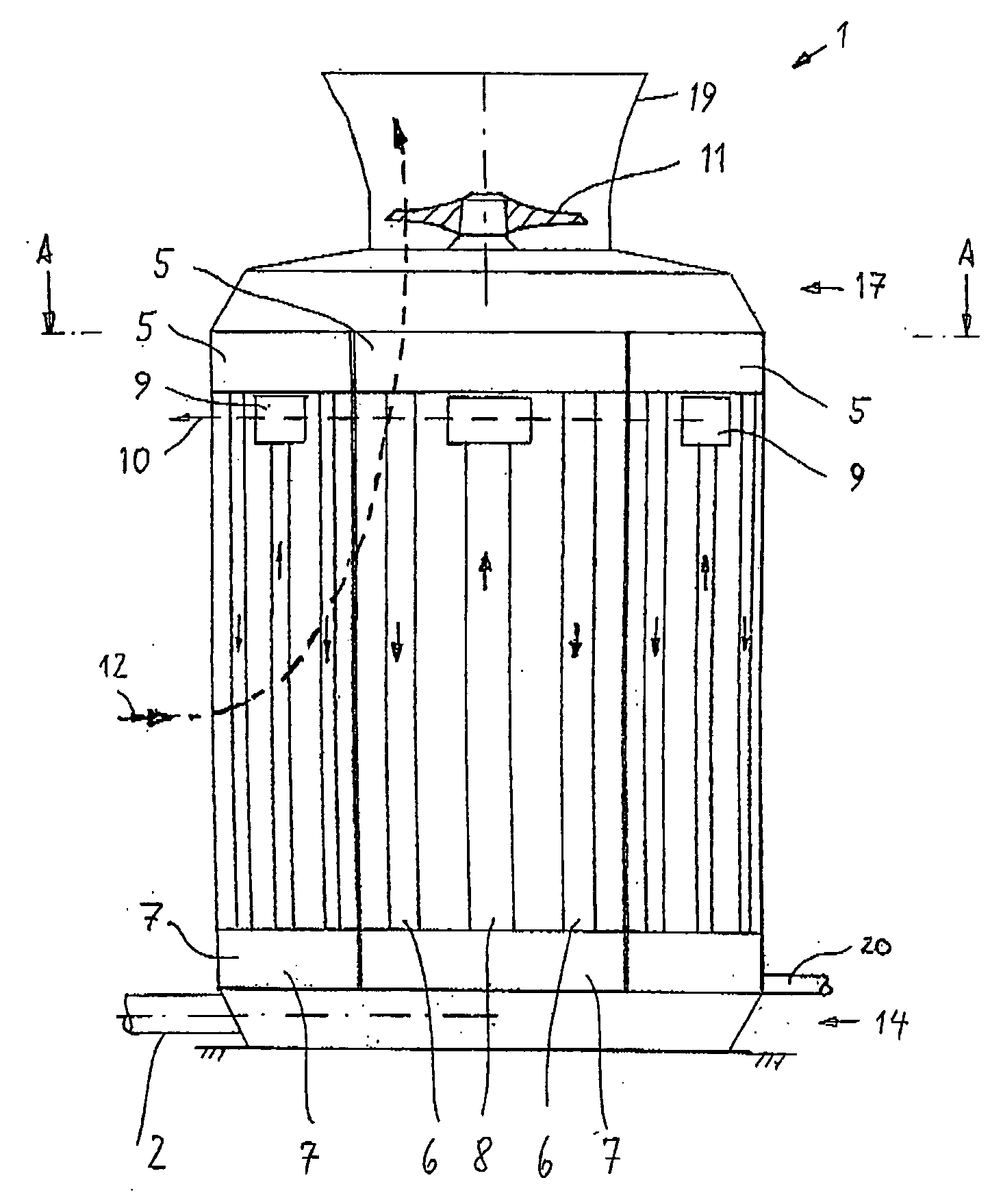

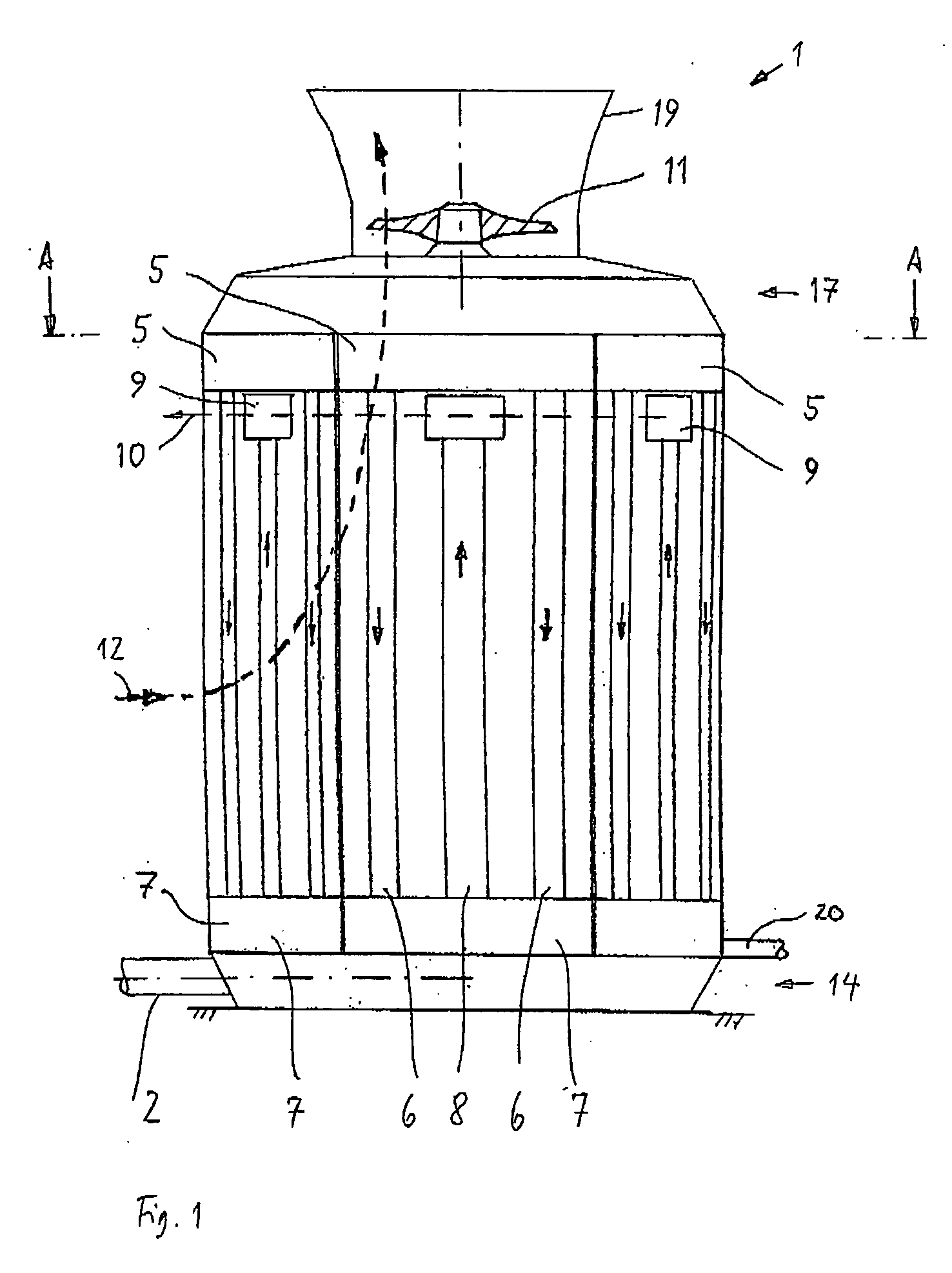

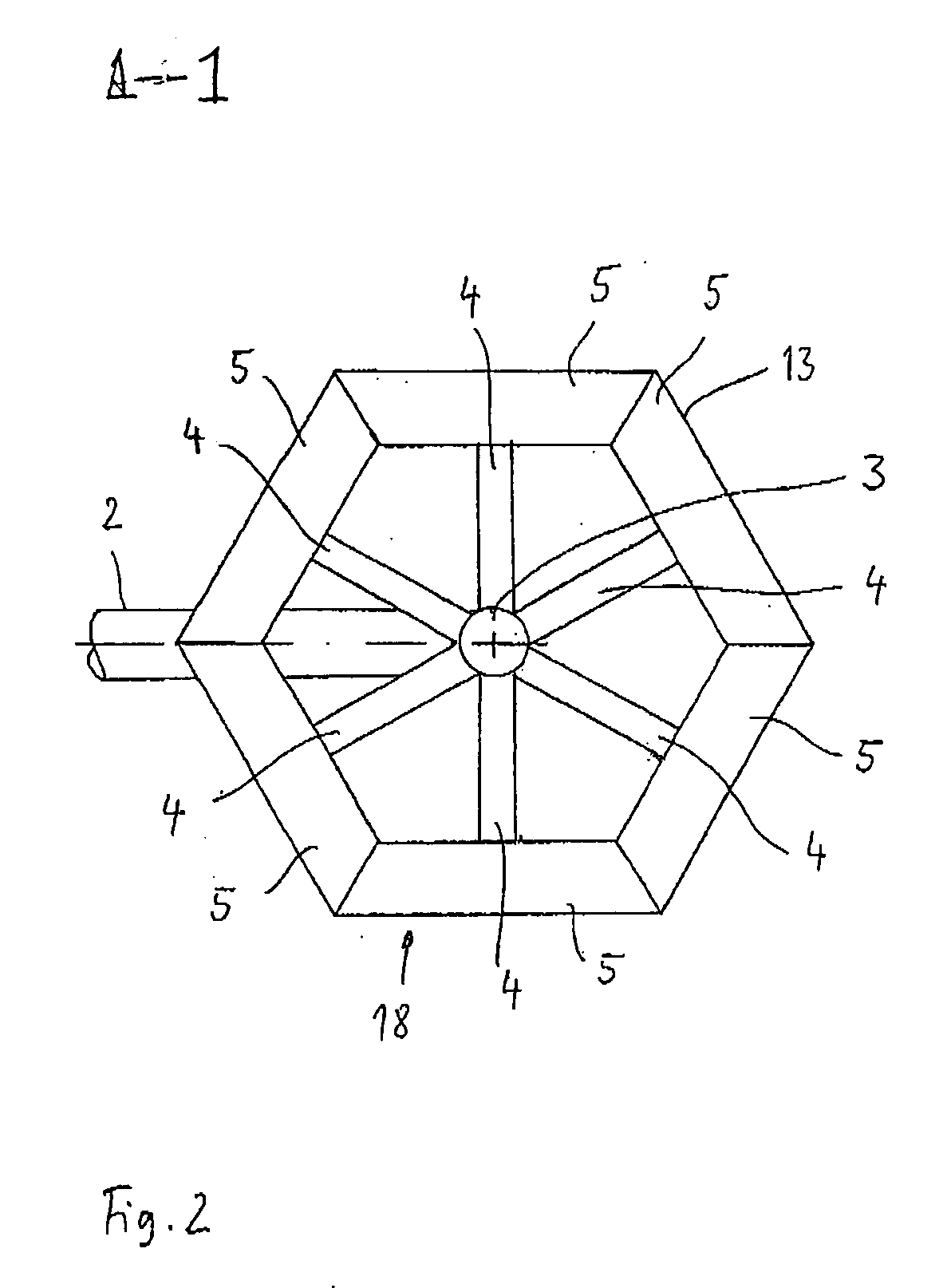

[0022] As is apparent from FIG. 1 and FIG. 2, steam is supplied to the inventive air-cooled condenser 1 using a supply line 2. The steam thereby flows upwards by means of one or more riser ducts 3 and is distributed using distribution lines 4 into a respective distribution chamber 5. It should be pointed out that only one riser duct is illustrated in FIG. 2. The distribution lines are indicated only schematically in FIG. 2; they can be further expanded or divided into several lines toward the distribution chamber 5.

[0023] The distribution chambers 5 are arranged in the upper region of the air-cooled condenser. Below the distribution chambers 5, pipe bundles are arranged, which are indicated schematically using the reference numeral 6. 1, 2 or more pipe bundles can be provided to each sidewall 18 corresponding to the diameter of the fan. The hot steam in the pipe bundles condenses due to the heat exchange with the air flowing past the pipes.

[0024] The liquid condensed in the pipe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com