Patterns of electrically conducting polymers and their application as electrodes or electrical contacts

a technology of electrical conductors and polymers, applied in the direction of non-metal conductors, instruments, and semiconductor/solid-state device details, etc., can solve the problems of cumbersome process and expensive tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

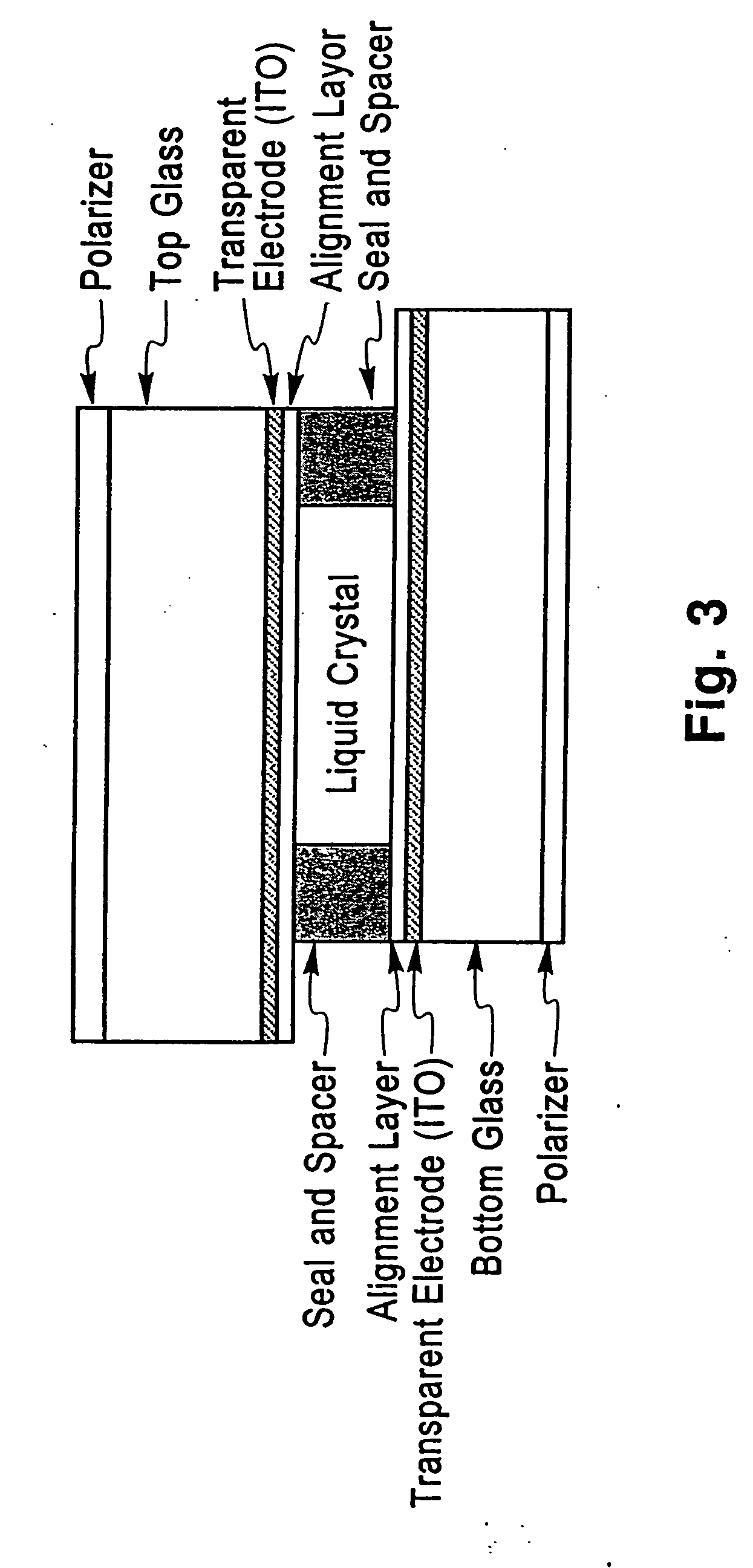

[0138] The present invention is directed to devices using electrically conducting polymers including substituted and unsubstituted polyanilines, polyparaphenylenes, polyparaphenylene vinylenes, polythiophenes, polypyrroles, polyfurans, polyselenophenes, polyisothianapthenes, polyphenylene sulfides, polyacetylenes, polypyridyl vinylenes, combinations thereof and blends thereof with other polymers, copolymers of the monomers thereof. It is found that these polymers can be patterned lithographically to form electrically conductive patterns which can act as electrodes or electrical contacts in various electro-optical transducers and devices. The present invention is also directed to electro-optical transducers and devices consisting of one or more electrically conductive polymer electrodes.

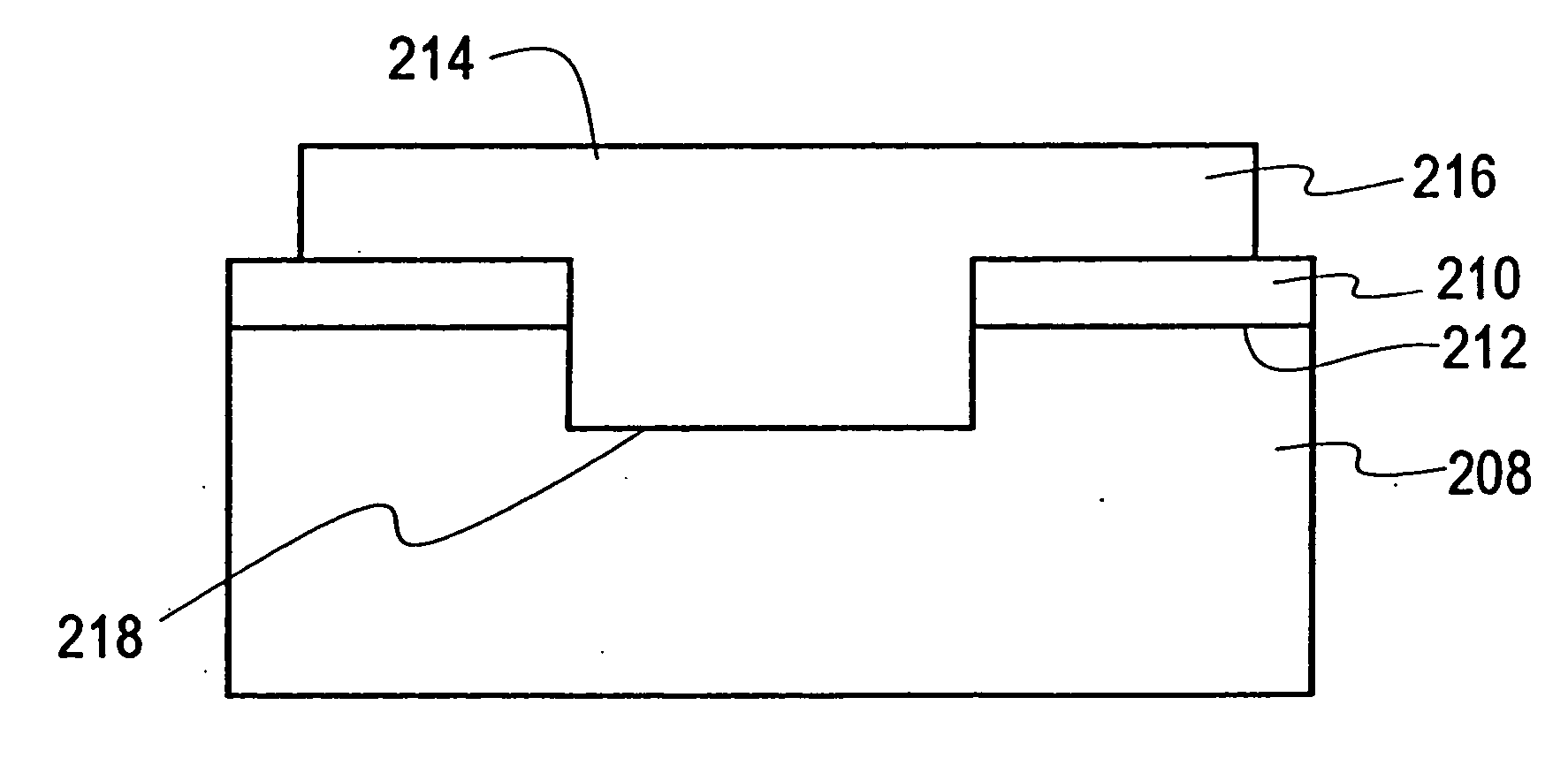

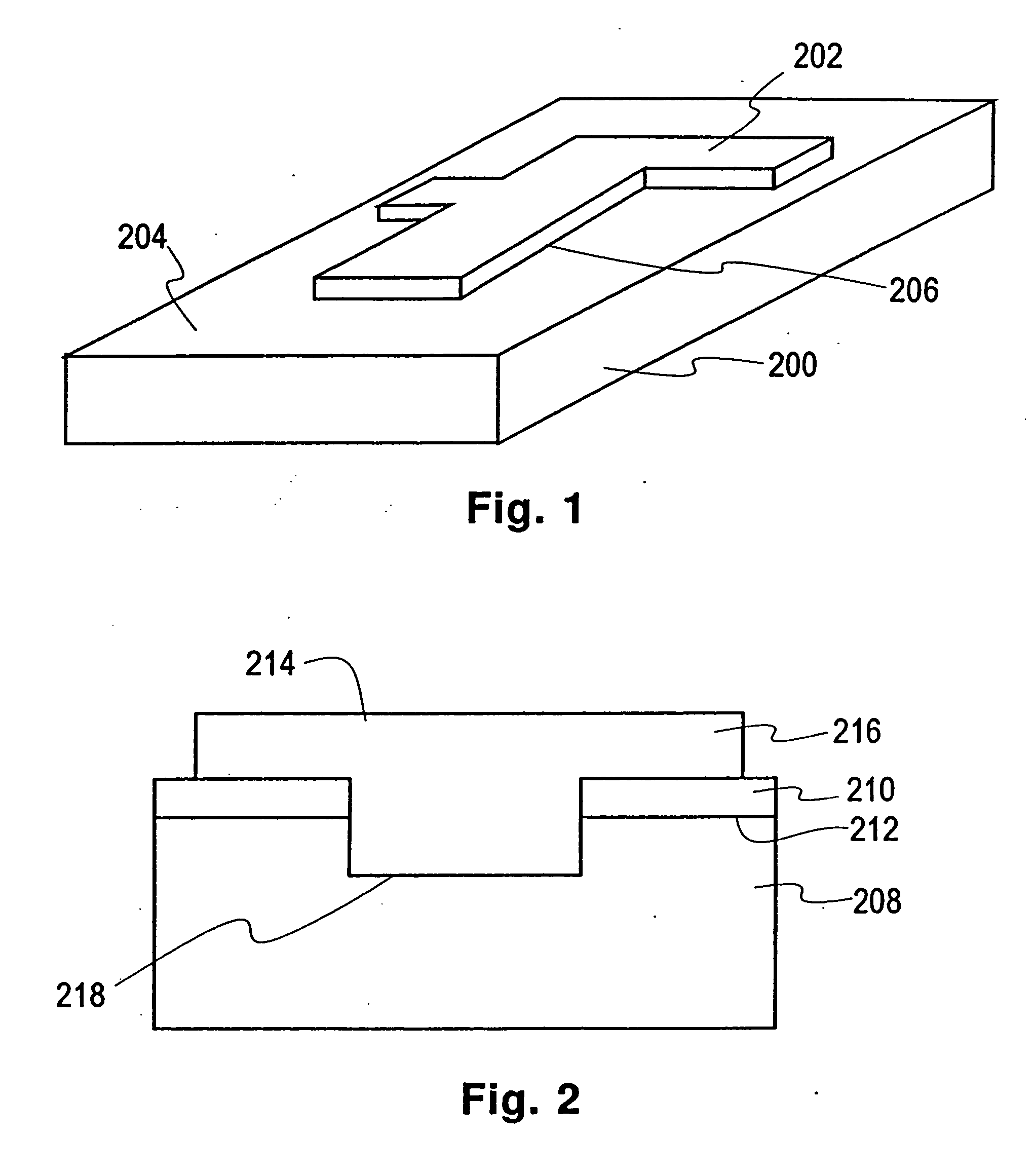

[0139]FIG. 1 schematically shows in perspective substrate 200 having patterned electrically conductive polymer 202 disposed thereon. The electrically conductive polymer 202 forms electrical contact t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com