Electroconductive thick film composition, electrode, and solar cell formed therefrom

a technology of electrodes and thick films, applied in the direction of non-metal conductors, conductors, organic conductors, etc., can solve the problem of difficult to obtain an electroconductive paste for connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

[0069] Application Example 1 is detailed below.

Manufacture of Electroconductive Paste

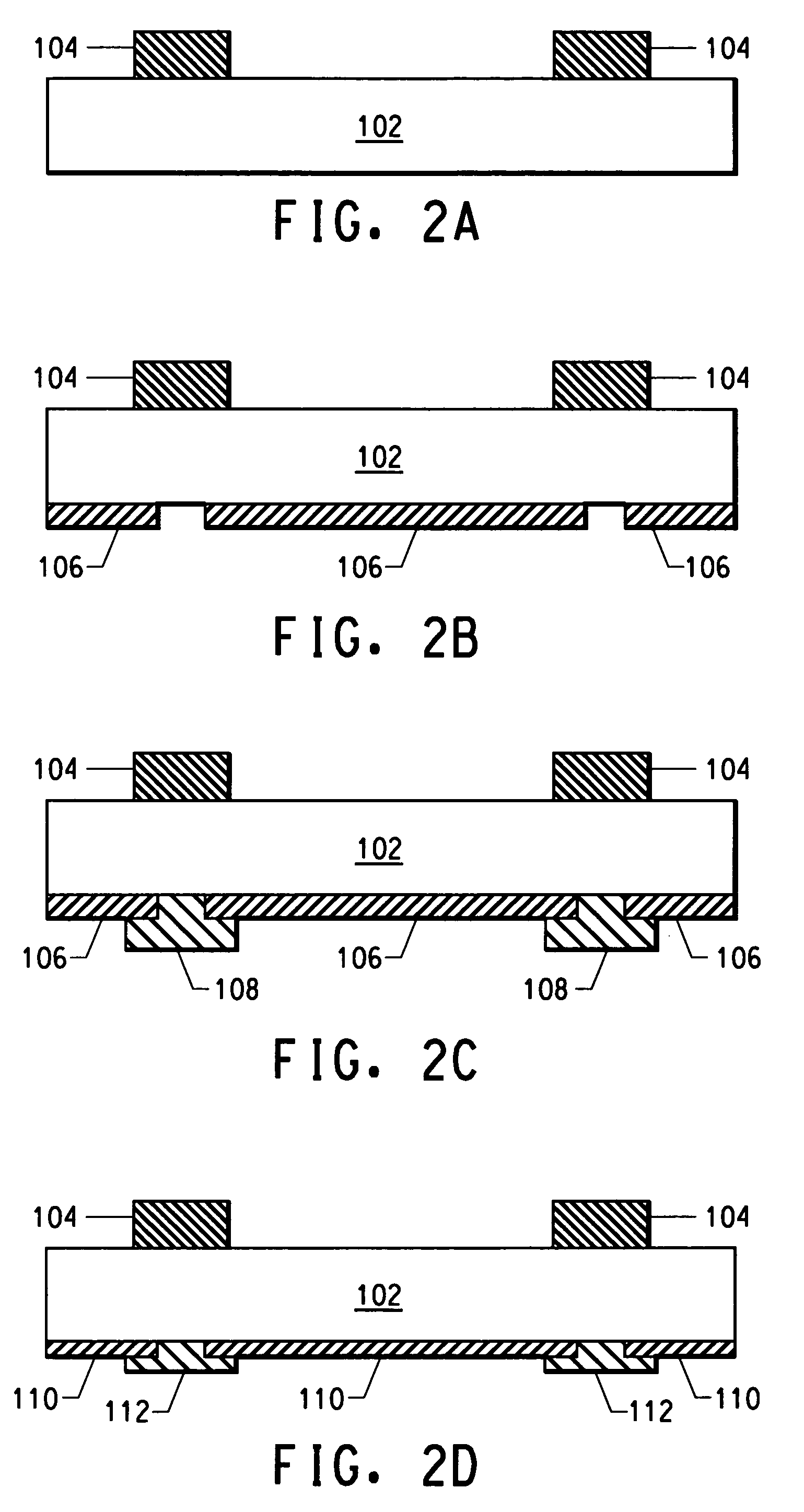

[0070] 1.7 wt % of a viscosity adjustor and 22.5 wt % of an organic vehicle (terpineol solution of ethylcellulose (containing 20 parts ethylcellulose)) were added to a mixture of 4.8 wt % glass frit (Si-B-Pb-O system) and 71.0 wt % silver powder with an average particle diameter of 8.5 μm. This mixture was premixed by a universal mixer and kneaded by a three-roll kneader, so that a silver electroconductive paste was obtained. The particle diameter, content, and characteristics of the materials used are shown in FIG. 2.

Manufacture of Solar Cell

[0071] Using the silver electroconductive paste obtained, a solar cell was formed in the following sequence.

[0072] (1) On the back face of a Si substrate having a silver electrode on the surface, an aluminum paste PV333 for the back face electrode of a solar cell (commercially available from E. I. du Pont de Nemours and Company) was screen-printed at a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com