Transparent resin concrete and preparation method thereof

A technology of transparent resin and concrete, applied in the field of civil engineering materials, can solve the problems of complex preparation process, high production cost, insufficient strength, etc., and achieve the effects of broad application prospects, good light transmission performance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

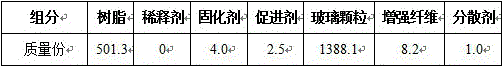

Embodiment 1

[0030] In a preferred embodiment of the present invention, the raw materials include: 501.2 parts by mass of resin, 0 parts by mass of diluent, 4.0 parts by mass of curing agent, 2.5 parts by mass of accelerator, 1389.6 parts by mass of glass particles, 8.2 parts by mass of reinforcing fiber , 1.0 parts by mass of reinforced fiber dispersant.

[0031]

[0032] The gradation of the glass particles is 9.5-13.2 mm in uniform particle size.

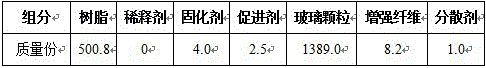

Embodiment 2

[0034] In a preferred embodiment of the present invention, the raw materials include: 501.3 parts by mass of resin, 0 parts by mass of diluent, 4.0 parts by mass of curing agent, 2.5 parts by mass of accelerator, 1388.1 parts by mass of glass particles, 8.2 parts by mass of reinforcing fiber , 1.0 parts by mass of reinforced fiber dispersant.

[0035]

[0036] The gradation of the glass particles is a combined form of the gradation of the SMA-13 asphalt mixture excluding the standard particle size below 4.75mm.

[0037]

Embodiment 3

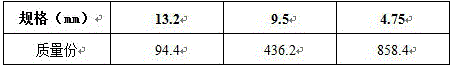

[0039] In a preferred embodiment of the present invention, the raw materials include: 500.8 parts by mass of resin, 0 parts by mass of diluent, 4.0 parts by mass of curing agent, 2.5 parts by mass of accelerator, 1389.0 parts by mass of glass particles, 8.2 parts by mass of reinforcing fiber , 1.0 parts by mass of reinforced fiber dispersant.

[0040]

[0041] The gradation of the glass particles is a combined form of the gradation of the OGFC-13 asphalt mixture excluding the standard particle size below 4.75mm.

[0042]

[0043] The resin is an anti-yellowing unsaturated polyester resin with a viscosity of 0.3-0.5 Pa·s and a gelling time of 8-16 (25° C. / min).

[0044] The reinforcing fiber is an alkali-free chopped glass fiber, the tensile strength is 6.3-6.9 g / d in a standard state, and 5.4-5.8 g / d in a wet state. The density is 2.4~2.7g / cm 3 .

[0045] The main component of the accelerator is 94% styrene, 2% naphthenic acid, and 2% nickel soap, which is a blue-purp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com