Continuous casting mold and a continuous casting method of copper alloy

a technology of copper alloy and continuous casting method, which is applied in the field of continuous casting mold and continuous casting method of cu alloy, can solve problems such as fatigue strength, and achieve the effects of ensuring the quality of the final produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

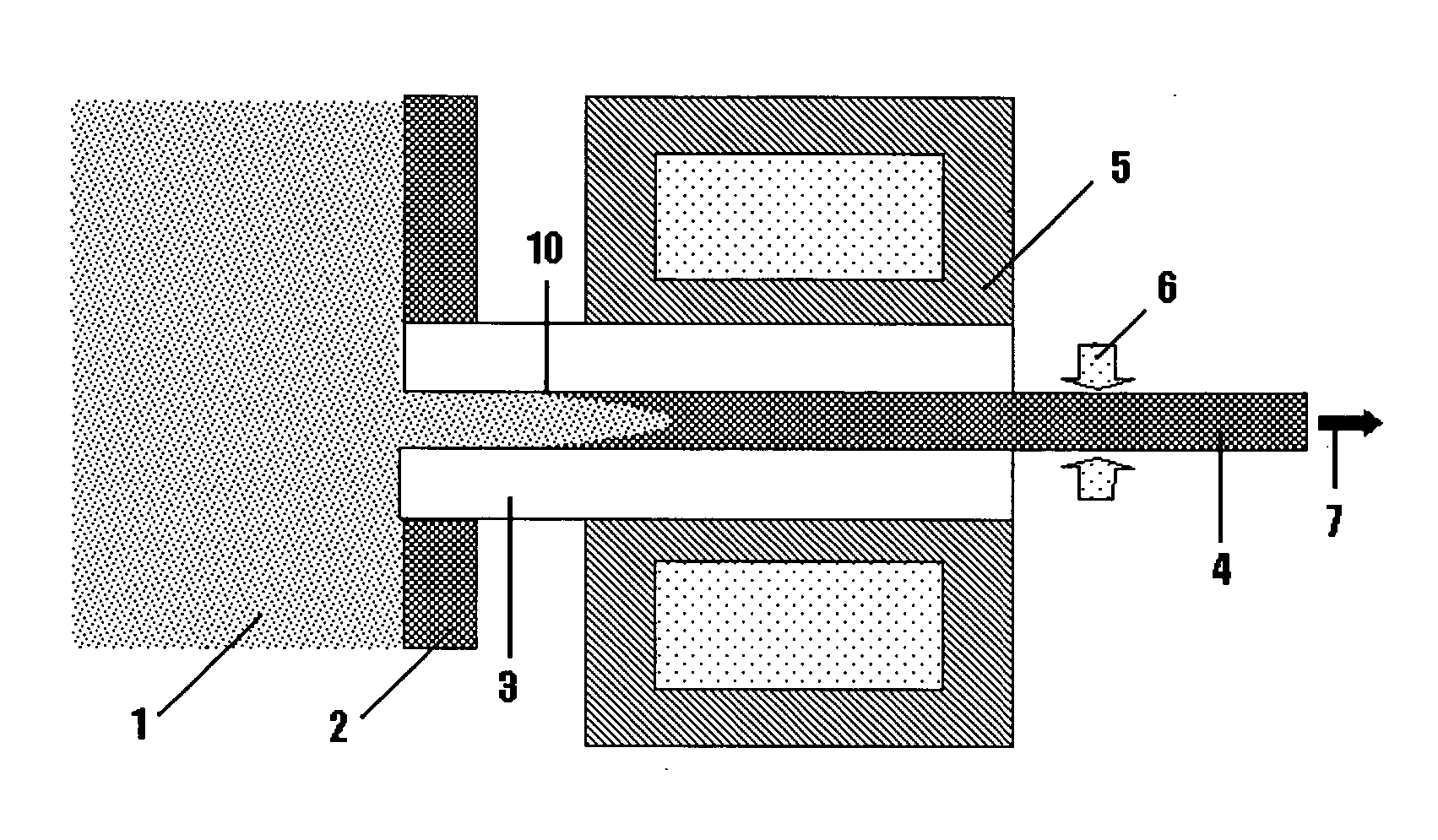

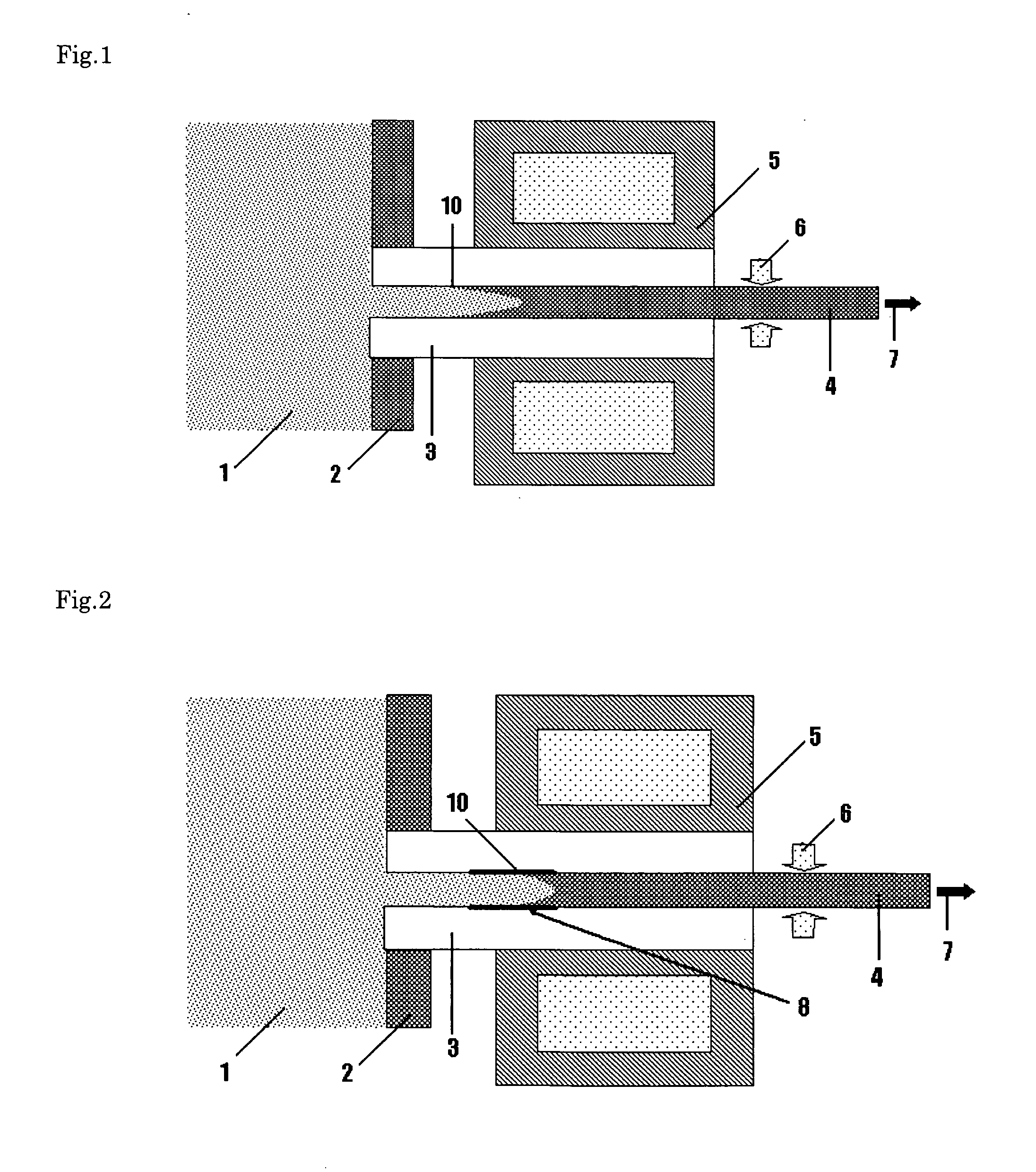

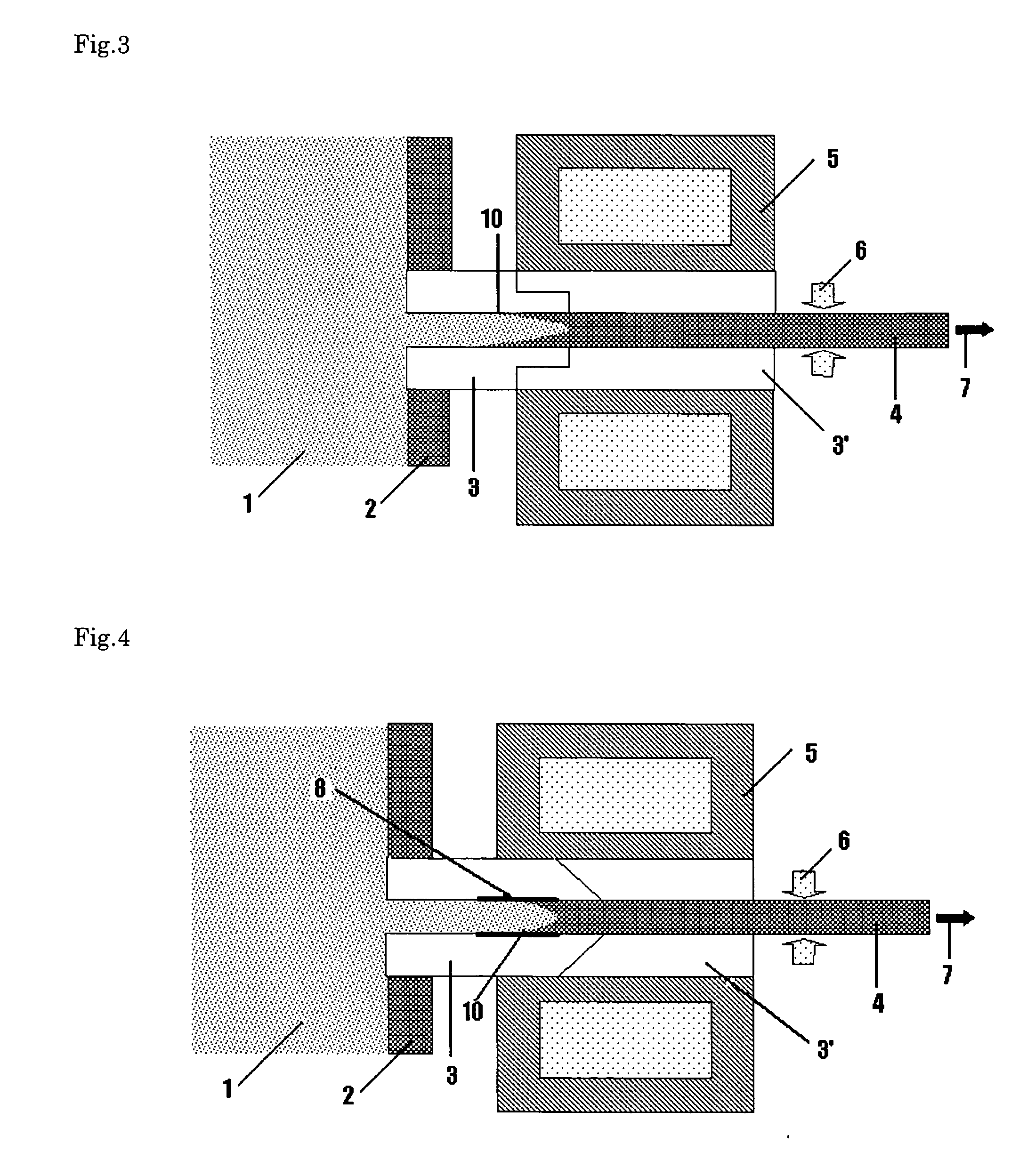

Image

Examples

example a

[0096] Cu alloys containing 2.0±0.1 wt % of Ti, 1.0±0.1 wt % of Cr, 0.4±0.02 wt % of Sn, and 0.1±0.01 wt % of Zn were melted in a high frequency vacuum melting furnace, and a continuous casting test was carried out in 30 kinds of various production methods shown in Tables 1 and 2. Each Cu alloy melt was transferred to a holding furnace, and a slab of 20 mm×200 mm section was intermittently pulled out in a predetermined condition while holding the temperature of the furnace at 1250° C. As a refractory of the melting furnace and the holding furnace, graphite was used. The oxidation of the melt was suppressed by an Ar gas flow during pouring in addition to charcoal covering. In each test, a water-cooled jacket composed of the Cu alloy was located adjacent to the mold in order to perform primary cooling, and the slab leaving the mold was cooled again by an air-water mixed spray. The temperature measurement was performed basically after leaving the mold by use of a thermocouple or radiat...

example b

[0101] There are 34 kinds of Cu alloys of the chemical compositions shown in Table 3, which were smelted similarly to Example A. A continuous casting test was carried out while varying the production condition, and they were evaluated in the same method as Example A. The results are shown in Tables 4 and 5. A satisfactory result was obtained in any mold, any casting condition and any chemical composition in the present invention. In contrast, an unsatisfactory result for quality was obtained using comparative molds.

TABLE 3AlloyNo.TiCrZrAgSnMnCoSiMgFeAlZnNiPOthers1—0.392.95————————————22.010.40—0.25——————————Mg: 0.1, Ca: 0.131.02 .200.99————————————42.991.01—————————————5—0.993.99————————————6—2.000.12———————————Li: 0.1, Sc: 0.570.981.97—5.00———————————83.01—2.01————————————91.014.00—0.10———————————105.000.99———————————0.001Nb: 0.2, Ge: 2.0113.010.97——0.41——0.49——0.51——Hf: 1.0, Bi: 0.512—0.981.99—0.10——0.201.00——0.21———131.980.99——0.35——0.04——0.29—1.500.001Sb: 1.1140.500.990.05————...

example c

[0104] For the three kinds of alloys shown in Table 6, slabs of 20 mm×200 mm section were casted by use of a mold composed of graphite with bulk density of 1.82, with a glassy carbon applied to the inner wall, and the influence of the cooling rate on characteristics was examined by varying the water quantities of primary cooling and secondary cooling, and varying the cooling rate from the solidification start point to 600° C. The cooled slabs were cold rolled to 3 mm, then aged at 400° C. for 2 hr under an inert gas atmosphere followed by cold rolling to 0.5 mm, and finally aged at 350° C. for 6 hr. The electric conductivity and tensile strength by tensile test of the resulting test materials were evaluated by the following methods.

[0105] [Table 6]

TABLE 6AlloyCoolingNo.TiCrZrrate(° C. / s)TS(MPa)IACS(%)Evaluation*RemarksComparative352.001.51—0.10——XNot evaluated because of cracking during cold rollingThe present352.011.51—0.5080240◯invention351.981.49—5.0095627◯351.991.51—10.00117419...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com