System and method for servo control of nonlinear electromagnetic actuators

a nonlinear electromagnetic actuator and servo control technology, applied in electrical control, non-mechanical valves, magnetic bodies, etc., can solve the problems of failure mode of print wire solenoids, insufficient basis for a servo system generating large mechanical motions and correspondingly large changes, and eliminate closure impact and associated noise, the effect of reducing the number of servos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Launch Control Methods

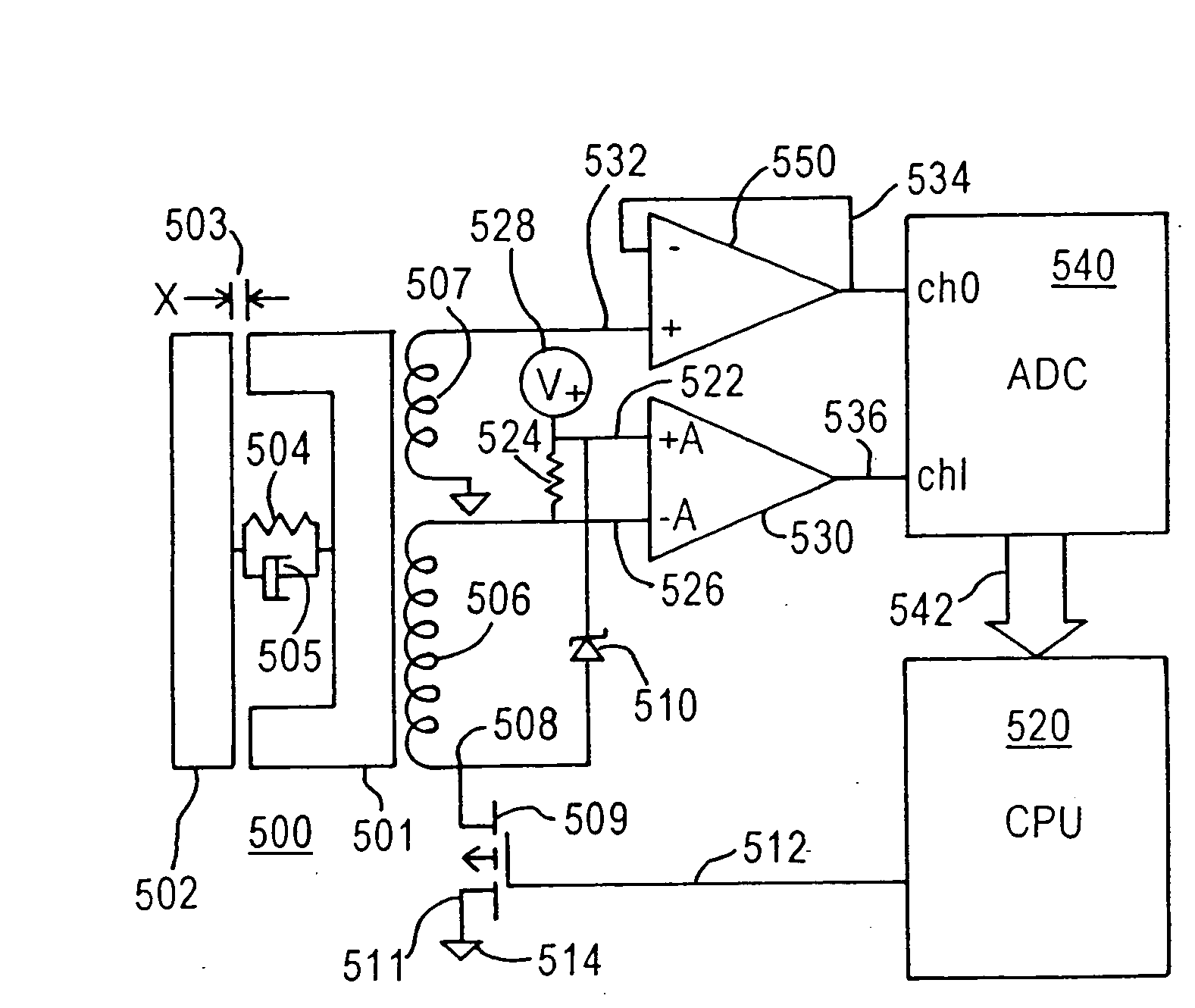

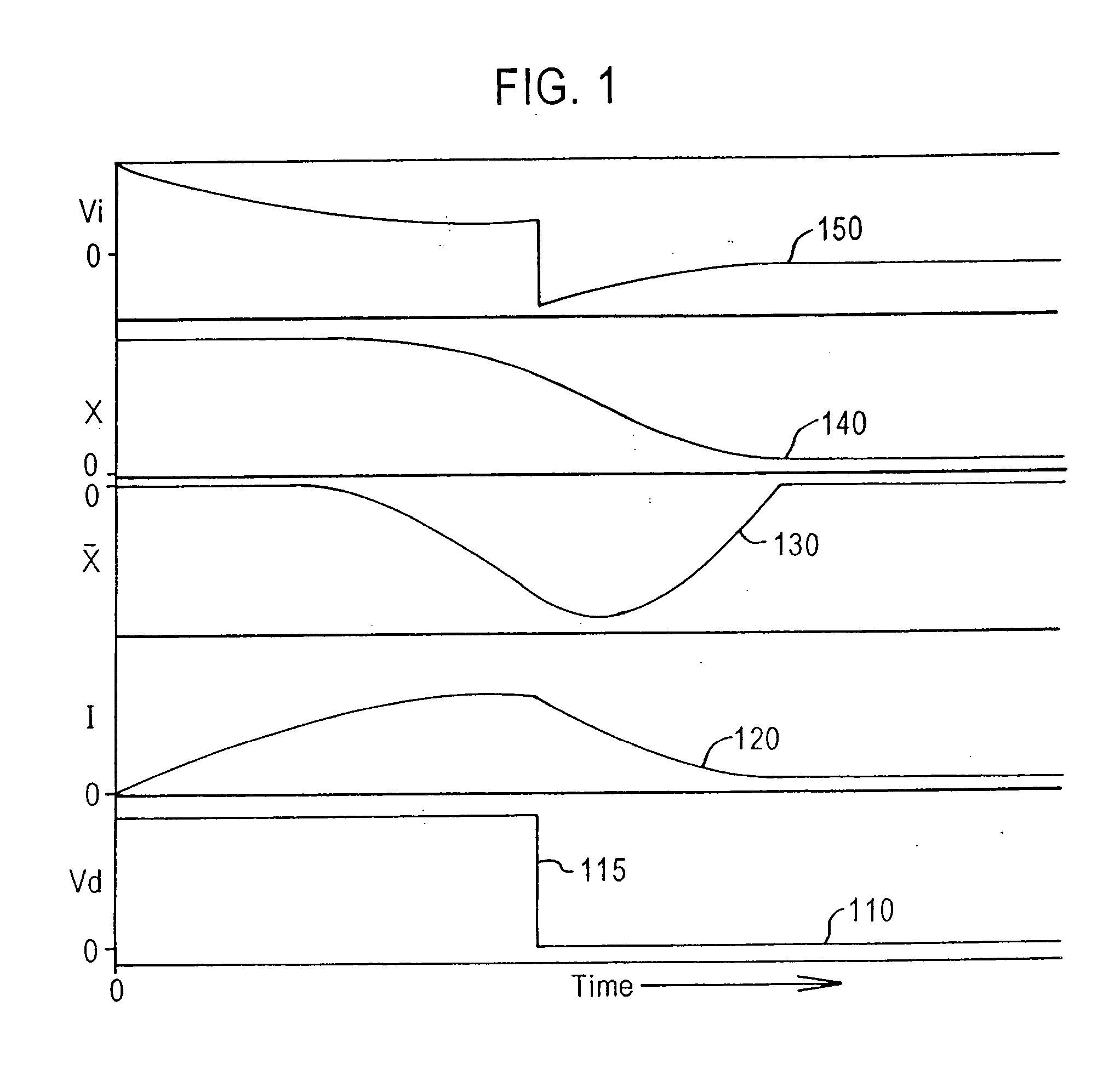

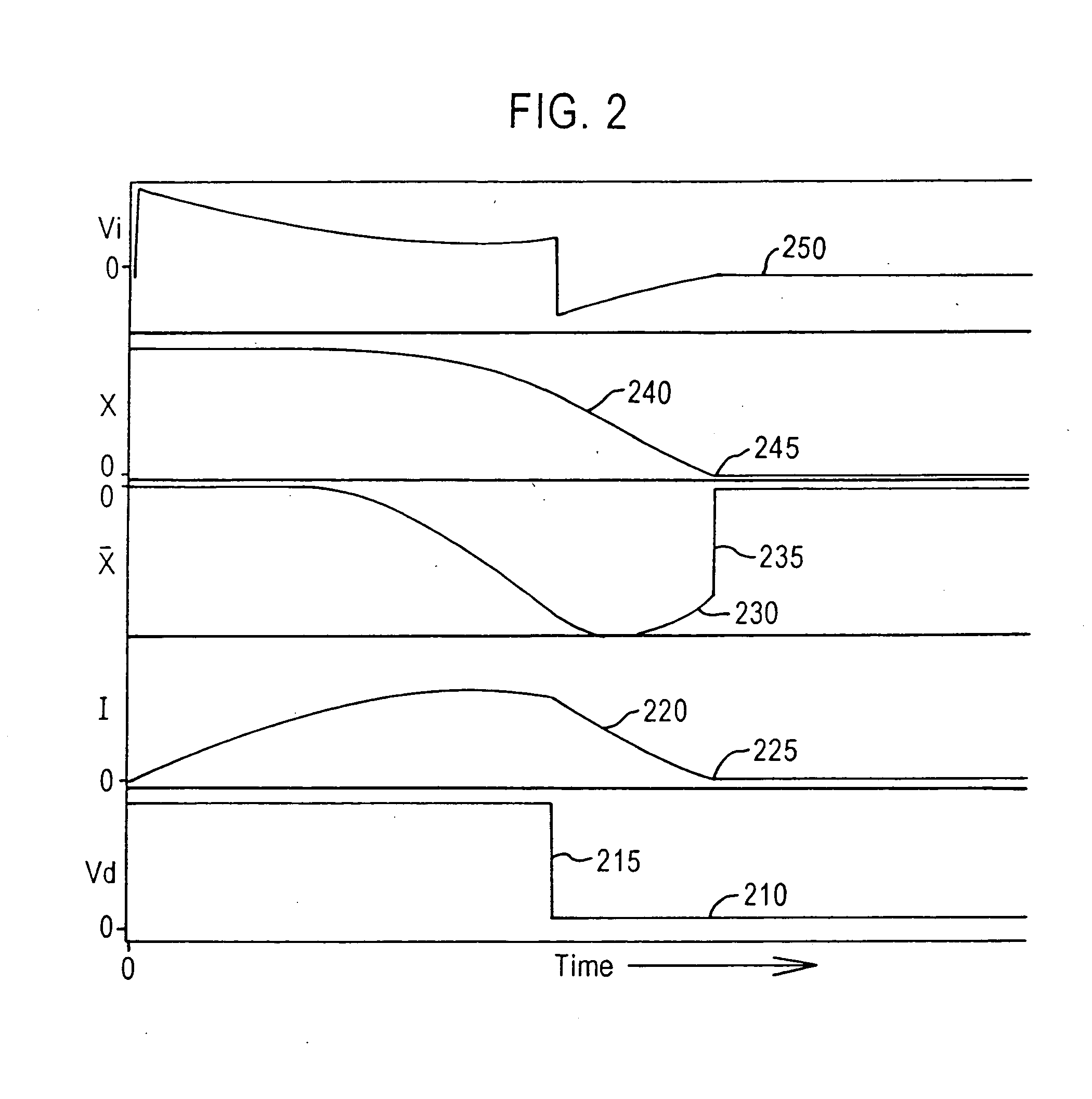

[0152] We have discussed the achievement of linear servo control, whose outcome is to establish a roughly exponential decay of error, including simple exponential decay and ringing within a decaying exponential envelope. A real solenoid controller has built in slew rate limits that set boundaries to the region of linear behavior and, consequently, the range of applicability of linear control methods. Typically, the solenoid driver amplifier operates between voltage output limits that set the maximum rate at which solenoid current can be increased and decreased. In the most common two-state output controller, the “on” output state drives current toward a maximum while the “off” output state short-circuits the solenoid winding through a transistor, allowing the current to vary and, ultimately, decay, in passive response to resistance and changing magnetic gap. The momentum attained by the solenoid shuttle falls into two categories: mechanical and electromagnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com