Channel steel rail flash welding machine

A technology of trough rail and flash welding machine, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of increased welding resistance, sticking, troubles, etc., and achieves the elimination of opening and closing interference related to sticking and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

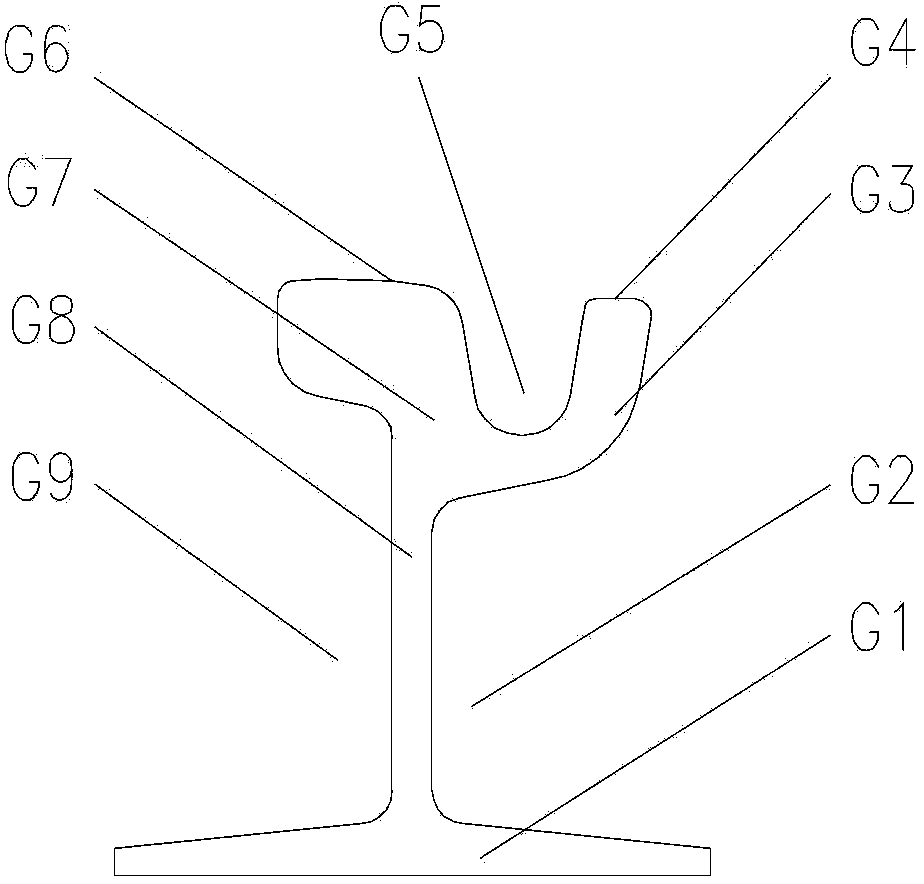

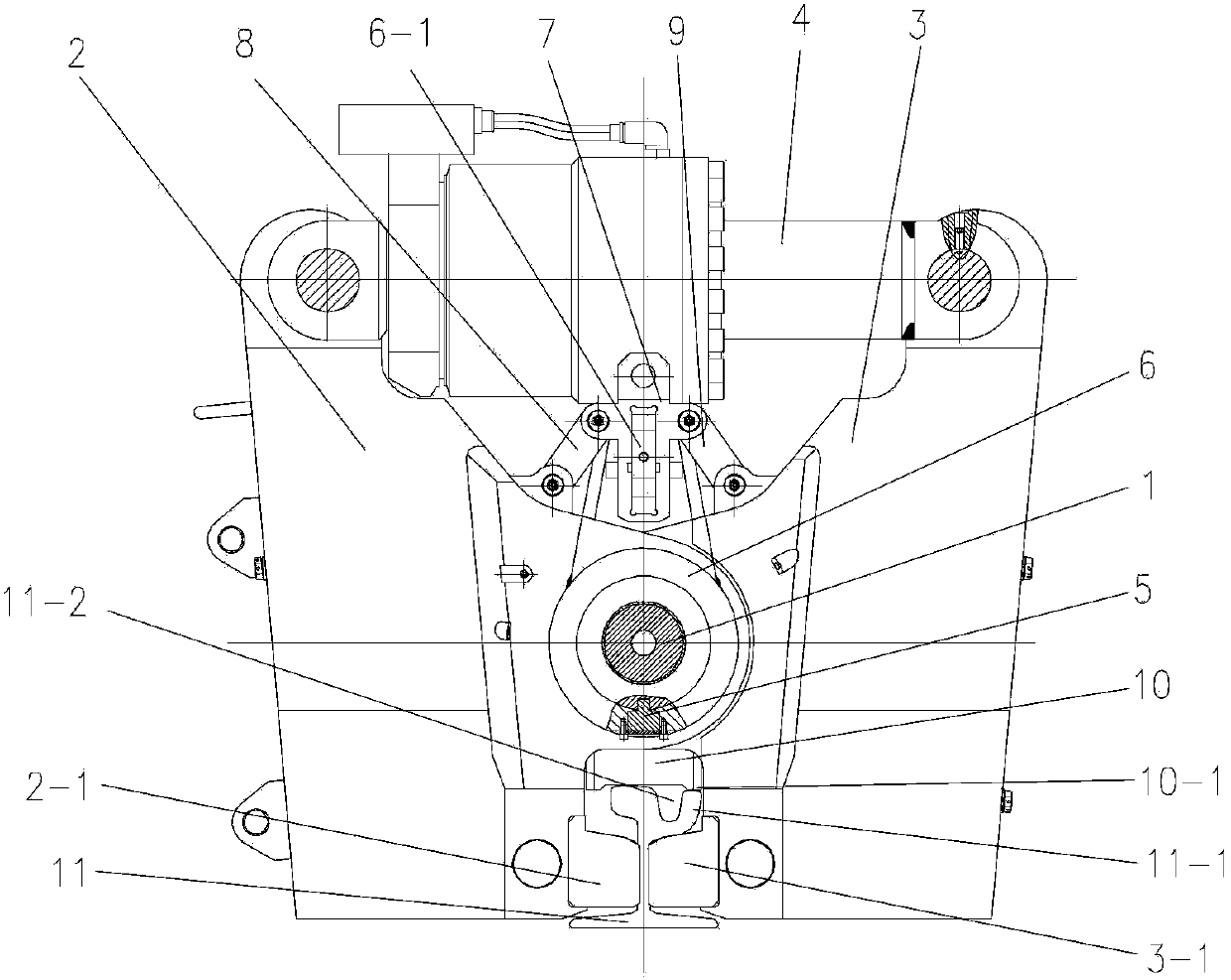

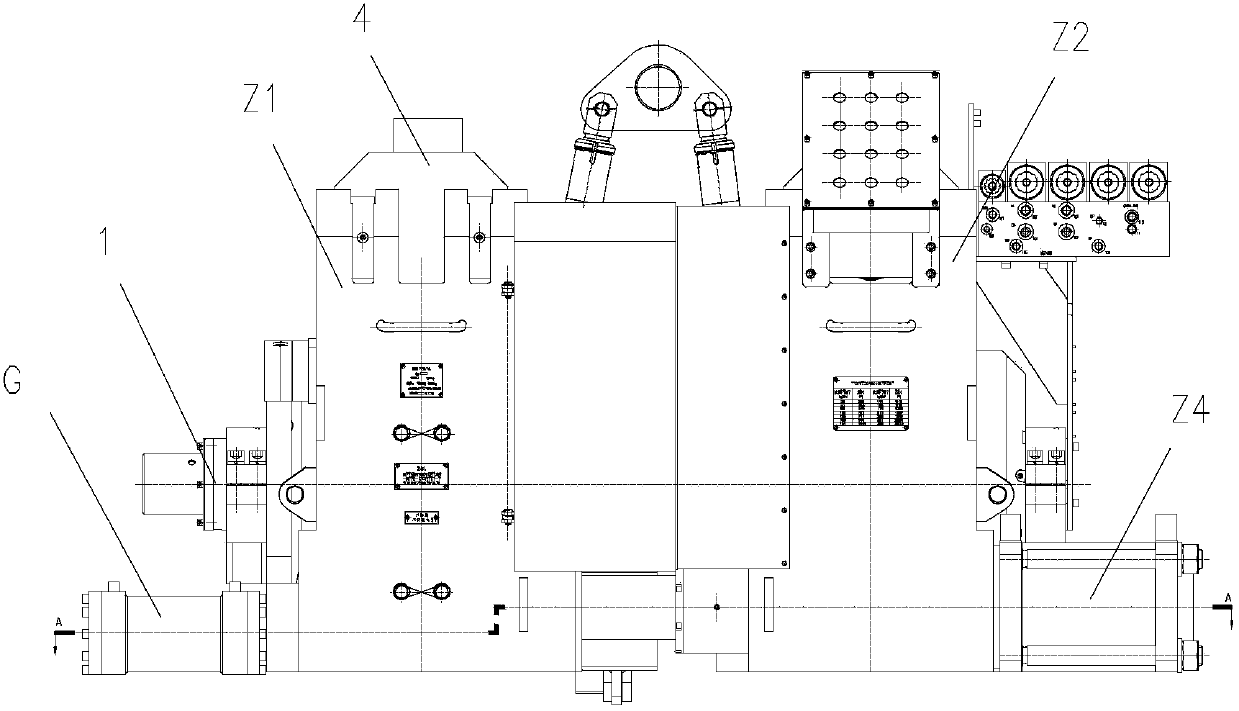

[0029] The basic structure of the channel rail flash welding machine of the present embodiment is as follows: figure 2 , 3 , 4, the lower part of the front box body part Z1 and the rear box body part Z2 constitutes a horizontal movement pair through the cylinder axis Z3. Front box body part Z1 and rear box body part Z2 are made of left and right clamp box body 2,3 and 2 ', 3 ' hinged on the central hinge shaft 1 respectively. The inner end of the front box body part Z1 is equipped with a tumor-removing knife T, and the outer end is equipped with a tumor-removing oil cylinder G that drives the tumor-removing knife T. The outer side of the rear box body part Z2 is equipped with an upsetting oil cylinder Z4 that drives the relative movement of the front box body part Z1 and the rear box body part Z2. The welding transformer Z5 is placed in the left and right clamp boxes, and the lower parts of the left and right clamp boxes 2, 3 and 2', 3' respectively have left and right jaws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com