Columnar structured material, electrode having columnar structured material, and production method therefor

a technology of structured materials and columns, applied in the direction of crystal growth process, polycrystalline material growth, chemistry apparatus and processes, etc., can solve the problems of high reliability and difficulty in applying a process with ease, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment regarding

Columnar Structured Material

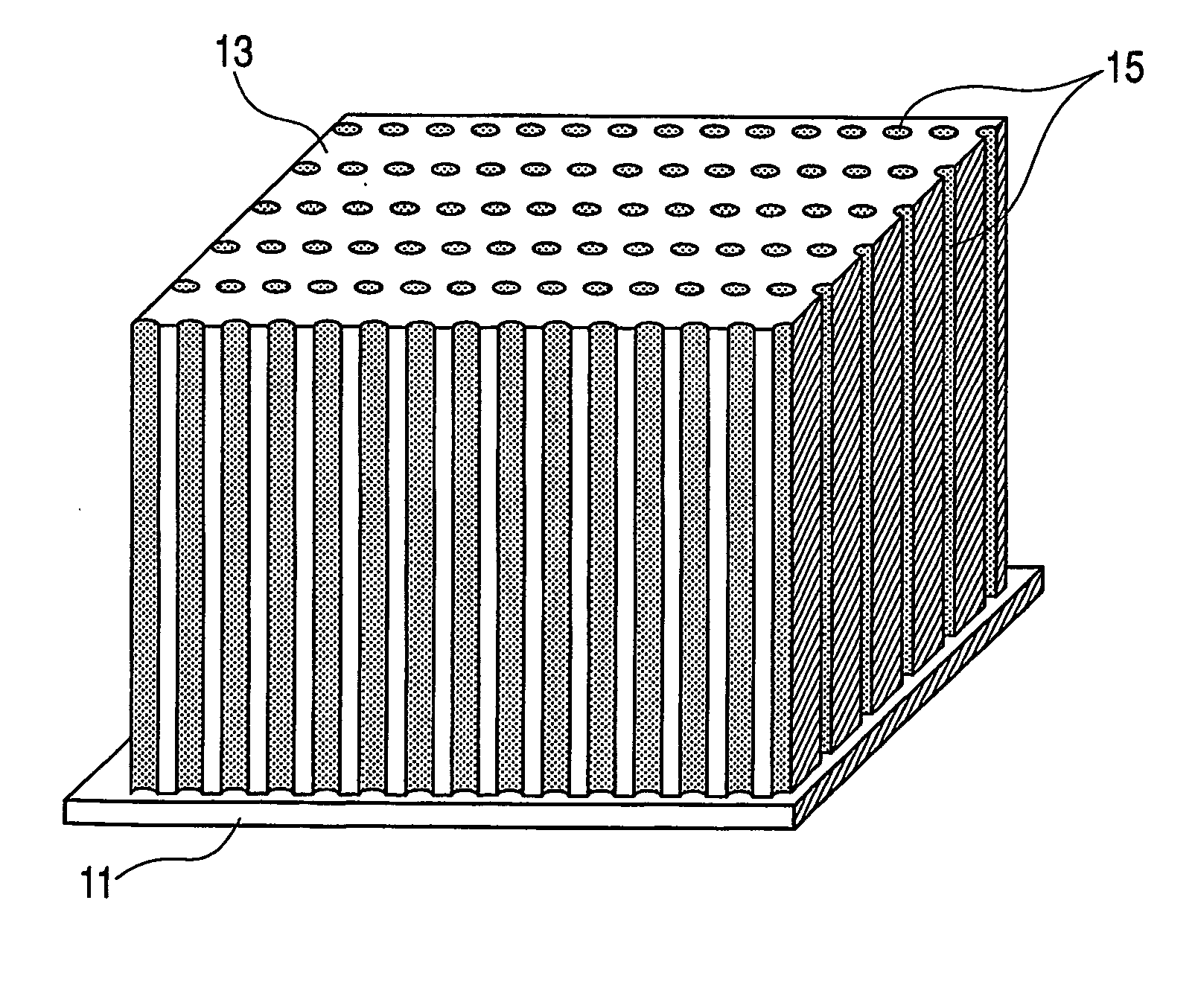

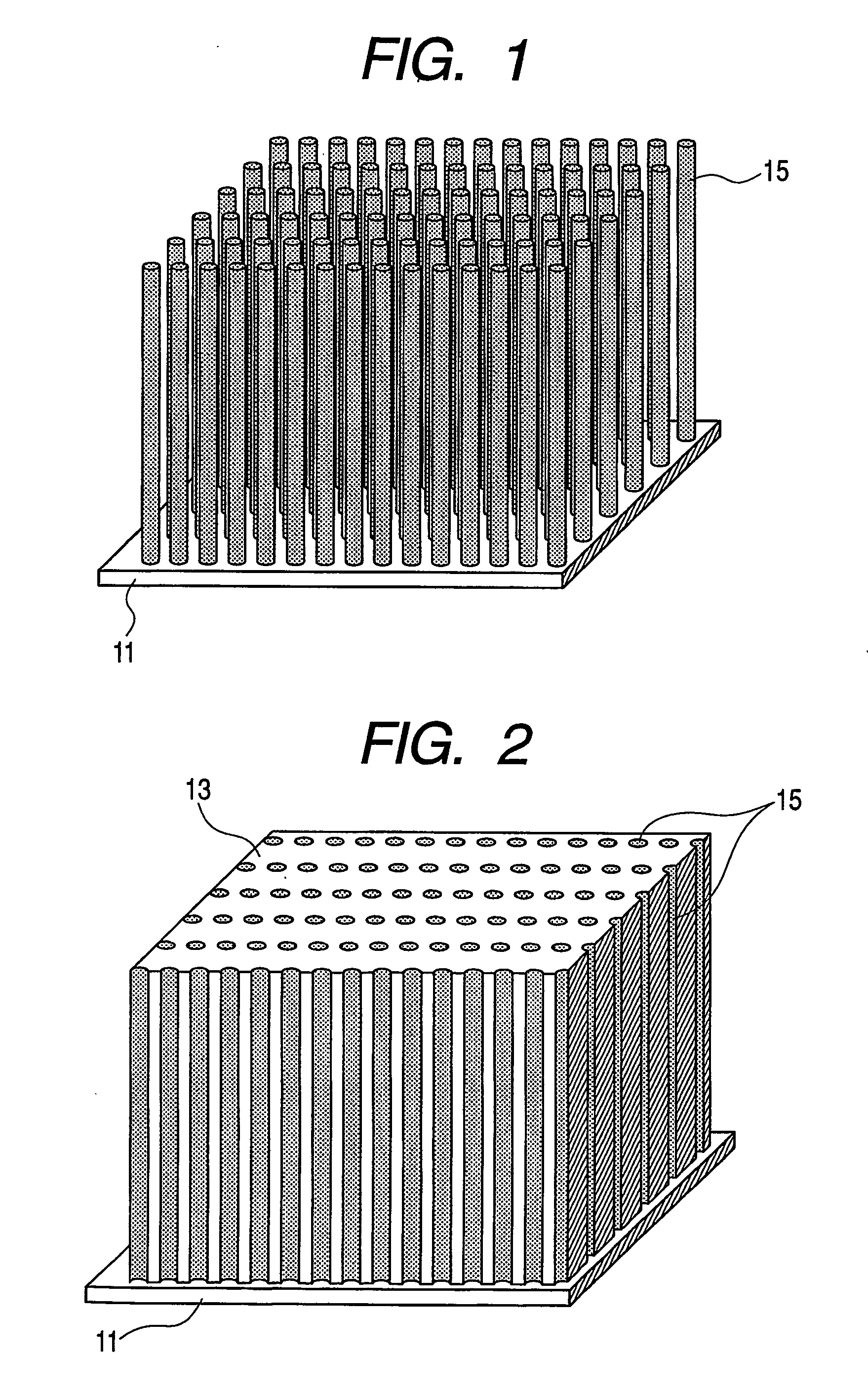

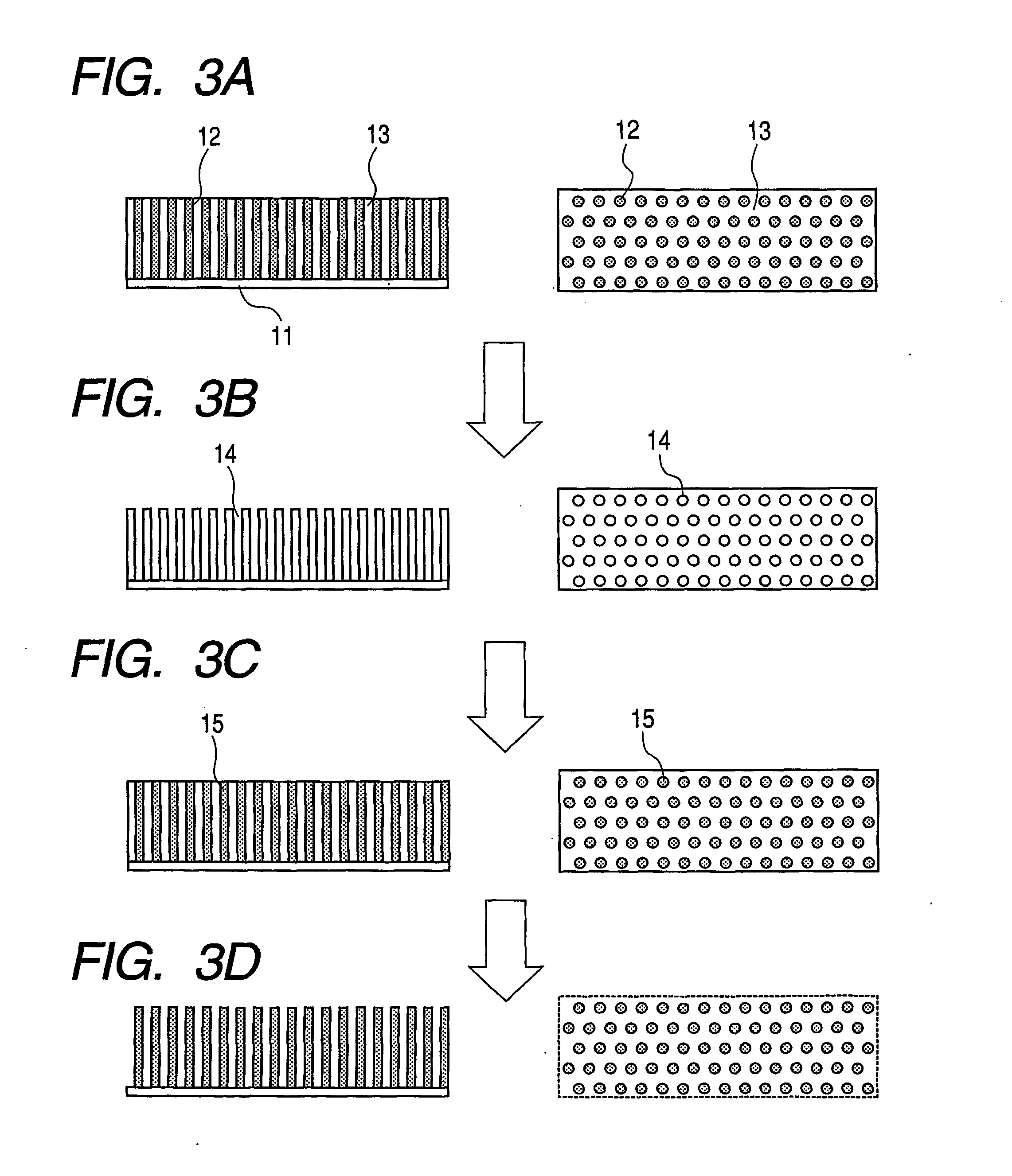

[0049] In the case where a film of a plurality of substances each included in a eutectic system is formed on a substrate by a method such as, for example, sputtering, respective components are independently present in the film without being mixed. In the case where film forming conditions and compositions of the substances are optimized for a specific material system, given components are formed into a columnar form having a minute diameter to form a structure in which the given components are dispersed within a matrix member of other components. The structure is a novel structured material discovered by the inventors of the present invention, in which columnar substances are present so as to penetrate from a substrate interface to a film surface. The diameter of one column of the formed columnar substances is in a range from 0.5 nm to 15 nm. Also, the interval between the columnar substances is in a range from 5 nm to 20 nm.

[0050] A specific example is ...

experimental example

First Material Al, Second Material Si

[0066] An aluminum microwire will be shown, in which an aluminum structured material portion surrounded by silicon has a columnar structure, a diameter 2r of 3 nm, an interval 2R of 7 nm, and a length L of 200 nm.

[0067] First, description will be made of a production method for an aluminum microwire.

[0068] An aluminum-silicon mixture film containing 55 atomic % of silicon with respect to the total amount of aluminum and silicon is formed into a thickness of approximately 200 nm on a glass substrate by RF magnetron sputtering. Used as the target was a 4-inch aluminum target on which eight silicon chips 13 of 15 mm square were arranged. Sputtering was performed using the RF power supply under conditions of an Ar flow rate: 50 sccm, a discharge pressure: 0. 7 Pa, and a starting power: 1 kW. Also, a temperature of the substrate was set to the room temperature.

[0069] Note that the aluminum target on which the eight silicon chips were arranged was ...

examples

[0112] Hereinafter, examples of the present invention will be described with reference to the drawings.

Examples Regarding Columnar Structured Material

Example 1

[0113] This example relates to an example in which aluminum and silicon are used as materials which form a eutectic, gold columnar microstructured materials are formed through electrodeposition in microholes of porous oxidized silicon that is obtained in such a manner that aluminum columns in a film are removed to obtain a porous silicon film, which is thereafter further oxidized, and then oxidized silicon in the vicinity is removed.

[0114] Through RF magnetron sputtering, an aluminum-silicon mixture film was formed into a thickness of 200 nm on a silicon substrate having 20 nm of tungsten deposited thereon. FIG. 4 schematically shows a target used. As shown in the drawing, the target is composed of six silicon chips 43 of 15 mm square arranged on 4 inches of an aluminum target 42 on a backing plate. The sputtering was perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com