Tie-type security seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

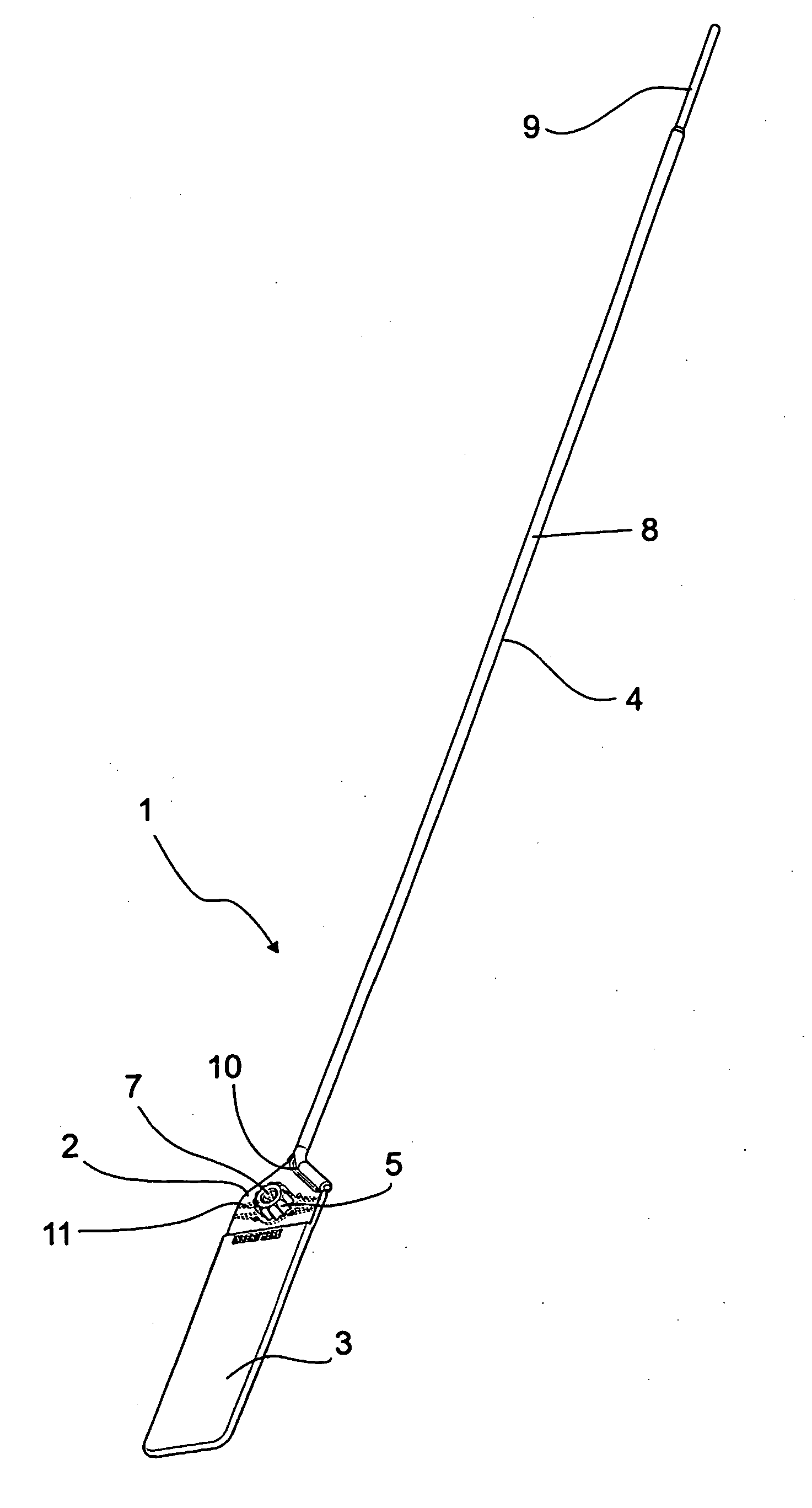

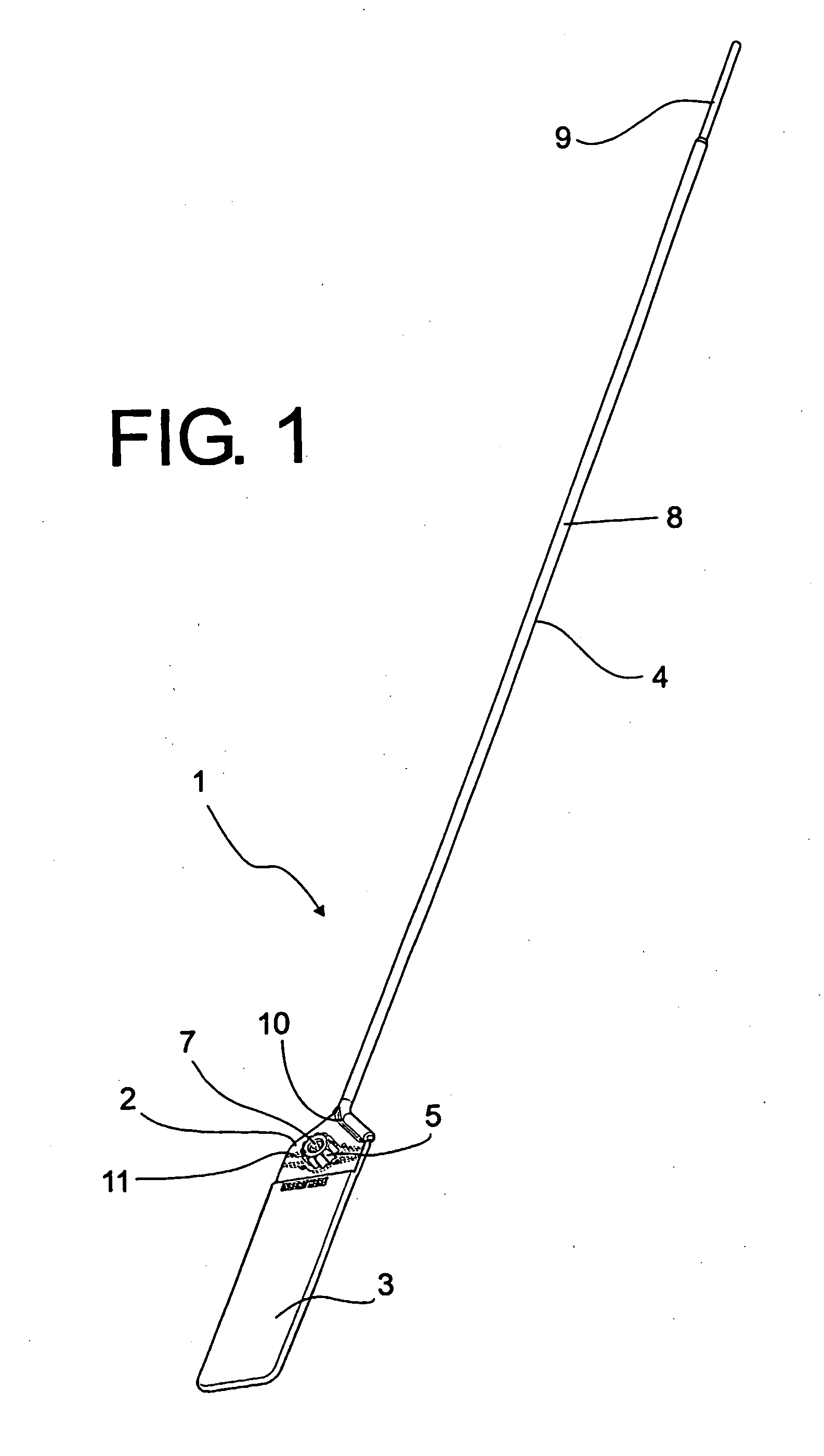

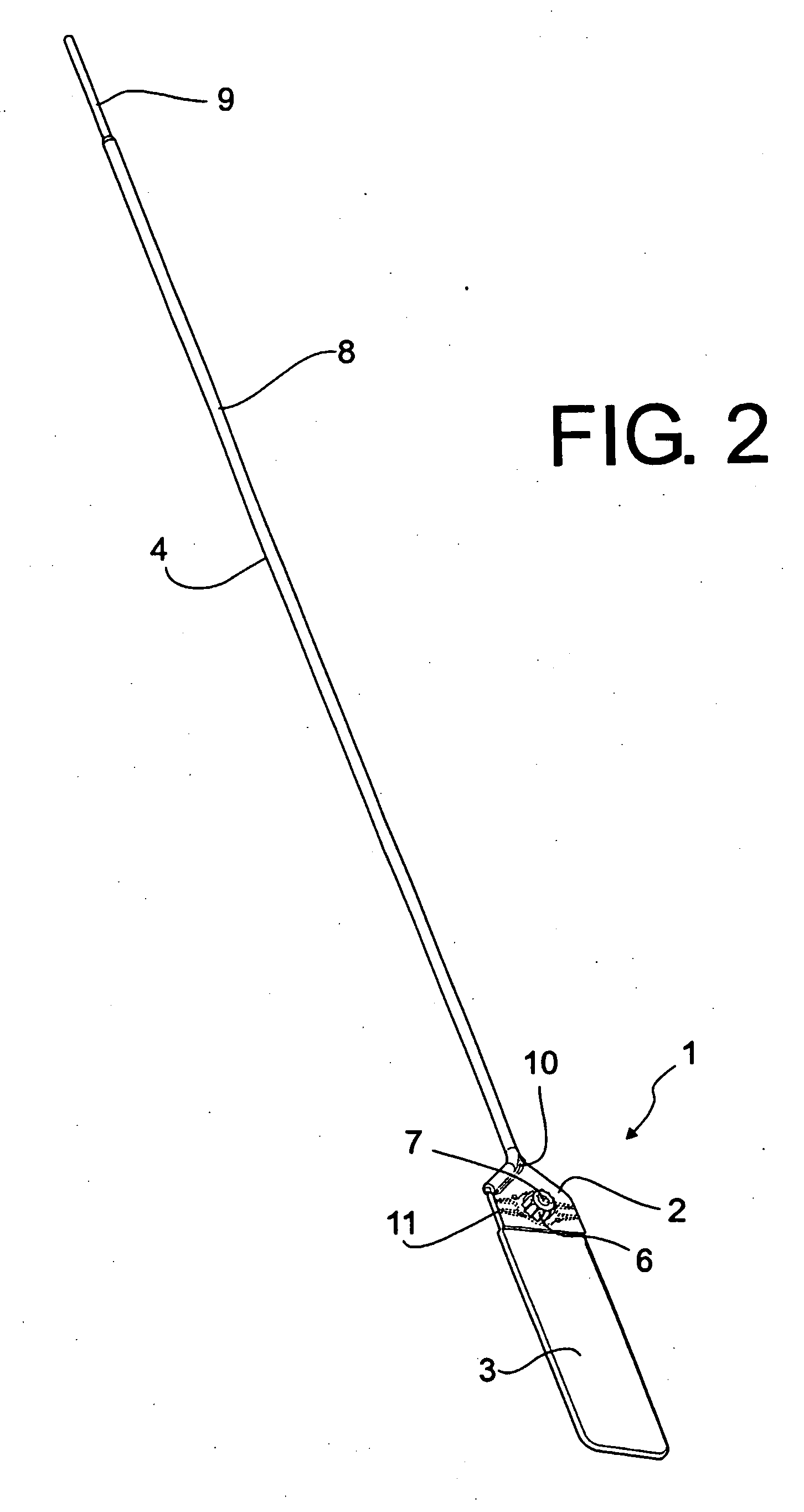

[0018] The seal 1 shown in FIGS. 1, 2 and 4 is moulded by injection of a thermoplastic, preferably polypropylene, nylon or polyethylene. The seal includes an body 2 integral, on one side, with a marking tab 3 for individualisation of the seal by means of a unique number, with or without equivalent information, such as a bar code, and with an elongated strip or tie 4 on the other side.

[0019] The body region 2 is formed with two protuberances 5 and 6 with a passage 7 through them to define a locking cavity for the strip 4. The cross section of passage 7 is substantially identical to that of the main part 8 of strip 4, which, however, becomes thinner at its free end 9 in order to facilitate its introduction ino the passage. The end or tip 9 of the strip is always be introduced though the side visible in FIG. 1, which is indicated by the word “Entry,” for a reason that will become clear later.

[0020] Strip 4 is connected to the body region 2 of the seal 1 by a weakened region 10 (see F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com