Cold spray formation of thin metal coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

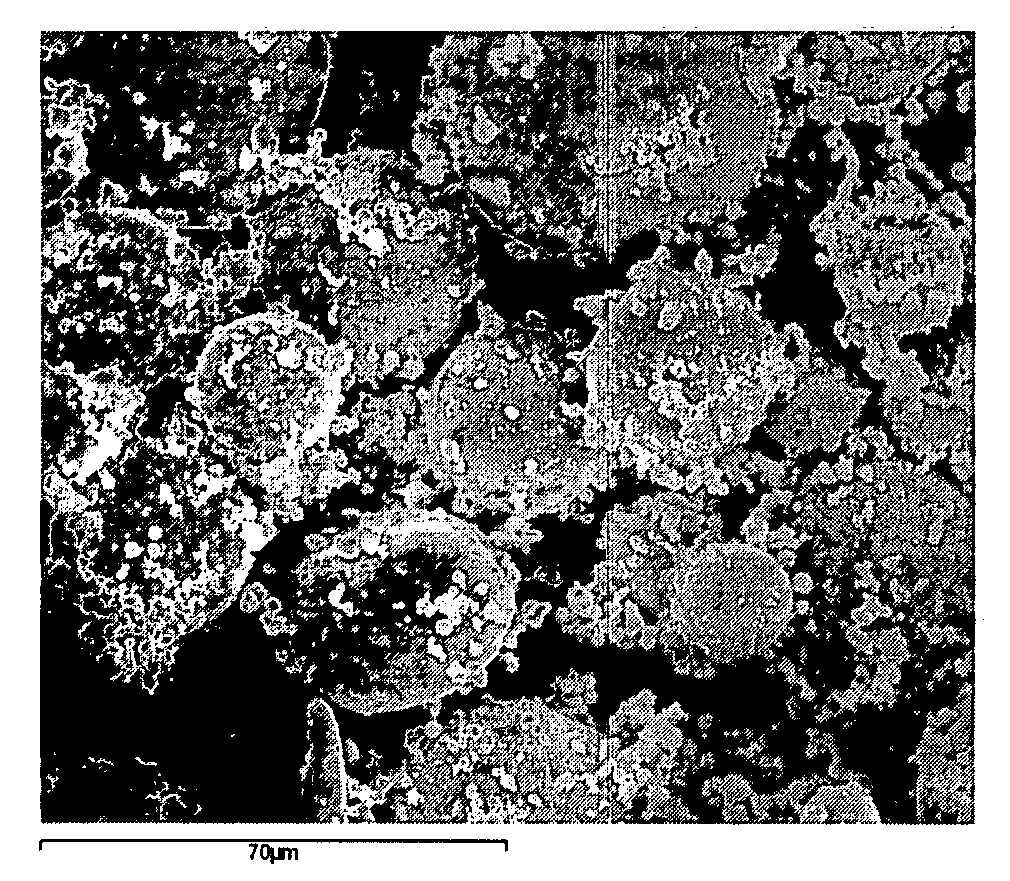

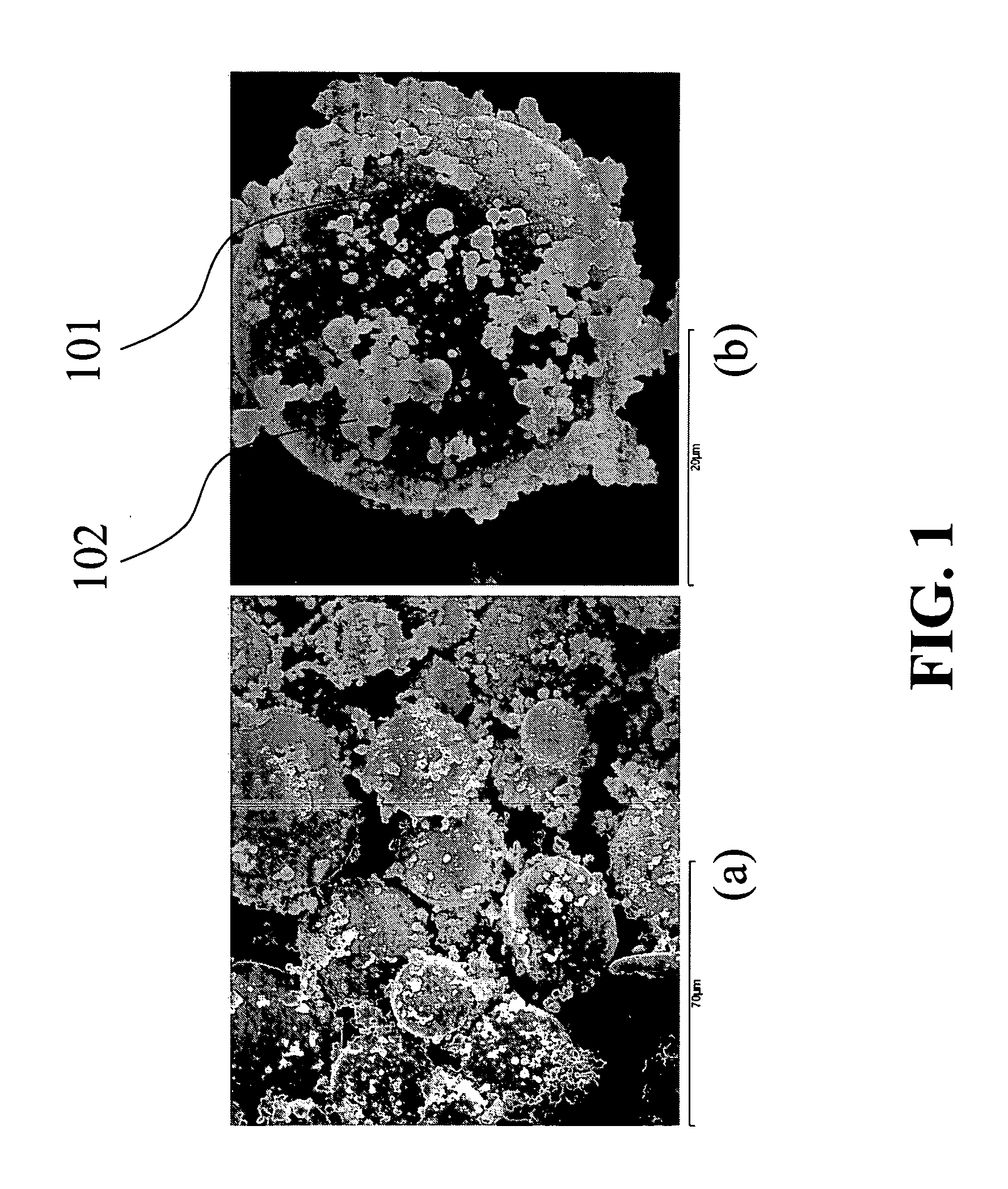

[0042] This example illustrates the formation of an agglomerate of the invention using aluminum as the metal powder.

[0043] A mixture of glass spheres (142.5 g, 170-400 mesh soda lime glass, Ceroglass Technologies Inc., Columbus Tenn.) and aluminum powder (7.5 g, 1-3 μm, Atlantic Equipment Engineers, Bergenfield, N.J.) was mixed (25 rpm) in a Reetz rotary furnace (HTM Reetz GmbH, Germany) for 0.5 h at 80° C. under an argon flow (0.5 L / min). The agglomerate was used directly in the cold spray process.

example 2

[0044] This example illustrates the formation of an agglomerate of the invention using copper as the metal powder.

[0045] A mixture of glass spheres (138.5 g, 170-400 mesh soda lime glass) and copper powder (12.5 g, 1.5-3 μm, Umicore Canada, Inc., Canada) is mixed (25 rpm) in a Reetz rotary furnace for 0.5 h at 70° C. under an argon flow (0.5 L / min).

example 3

[0046] In a similar manner to Example 1, nickel powder (7.5 g, 50-100 nm, Tekna RF Plasma Equipment, Canada) is treated with glass spheres (142.5 g) at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com