Refractory material for casting a rare-earth alloy and its production method as well as method for casting the rare-earth alloys

a rare-earth alloy and refractory material technology, applied in the direction of muffle furnaces, charge manipulation, furnaces, etc., can solve the problems of reducing the volume fraction of the r-rich phase, affecting the crushability of the alloy, and unsatisfactory properties, so as to improve the melt flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

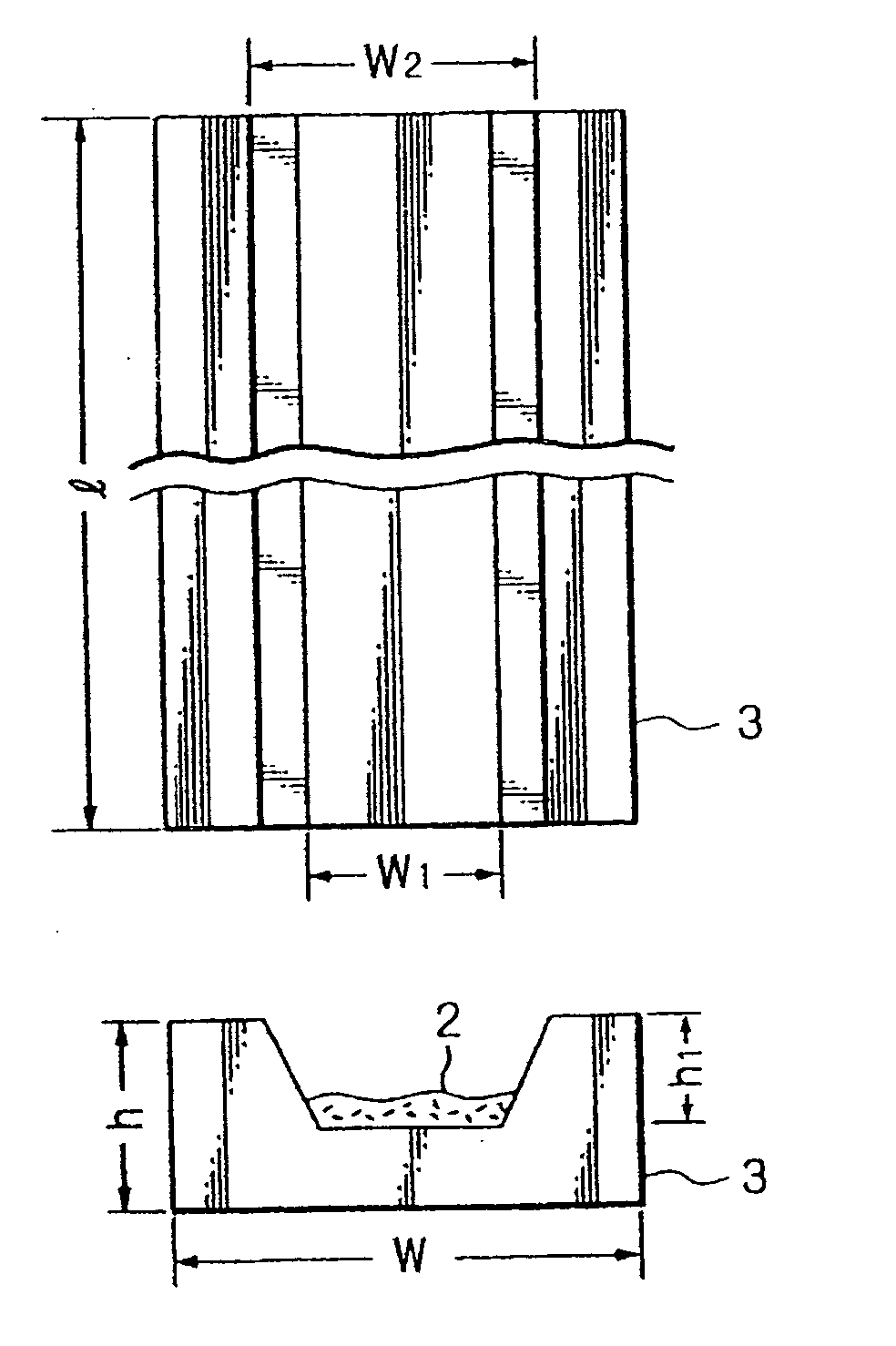

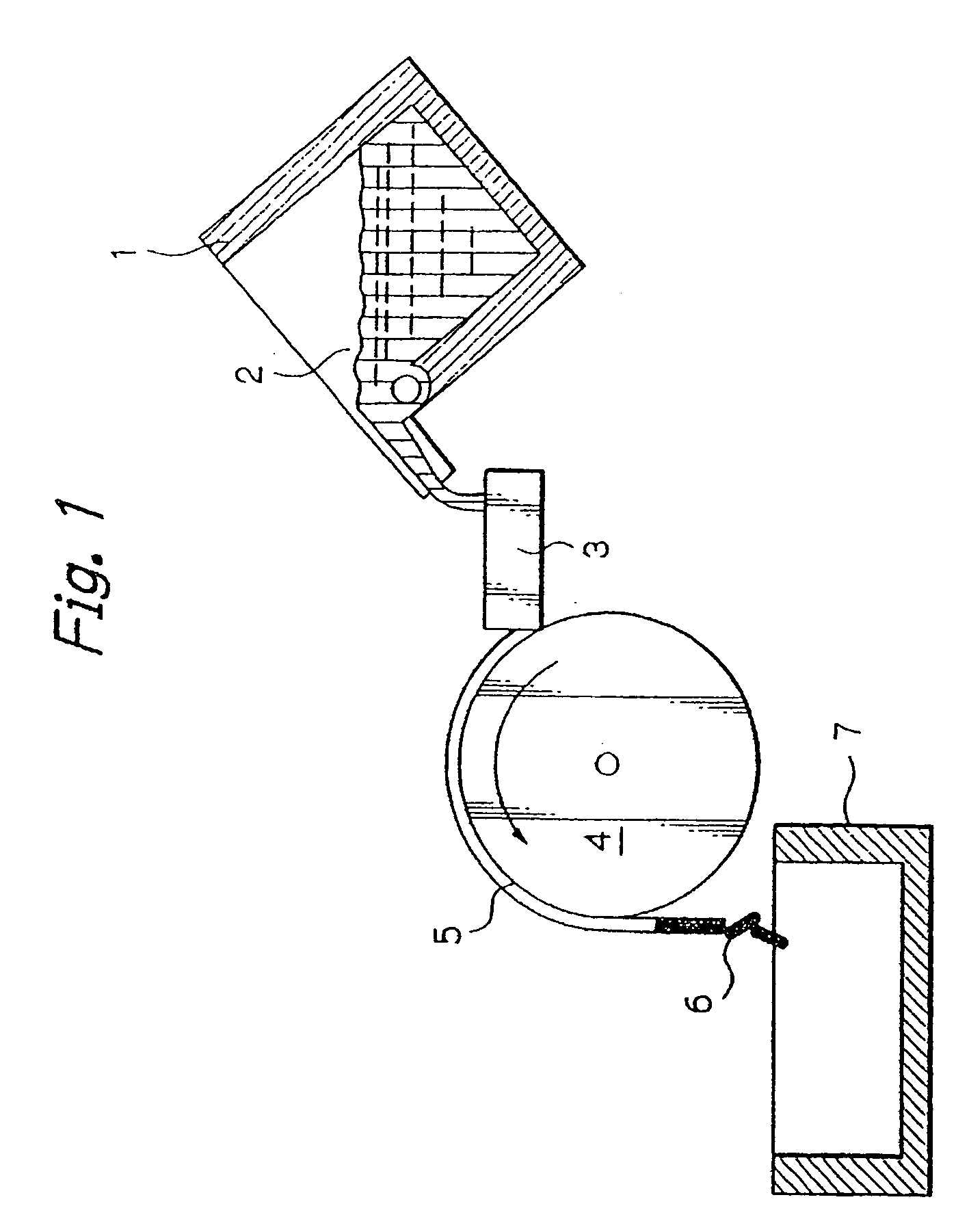

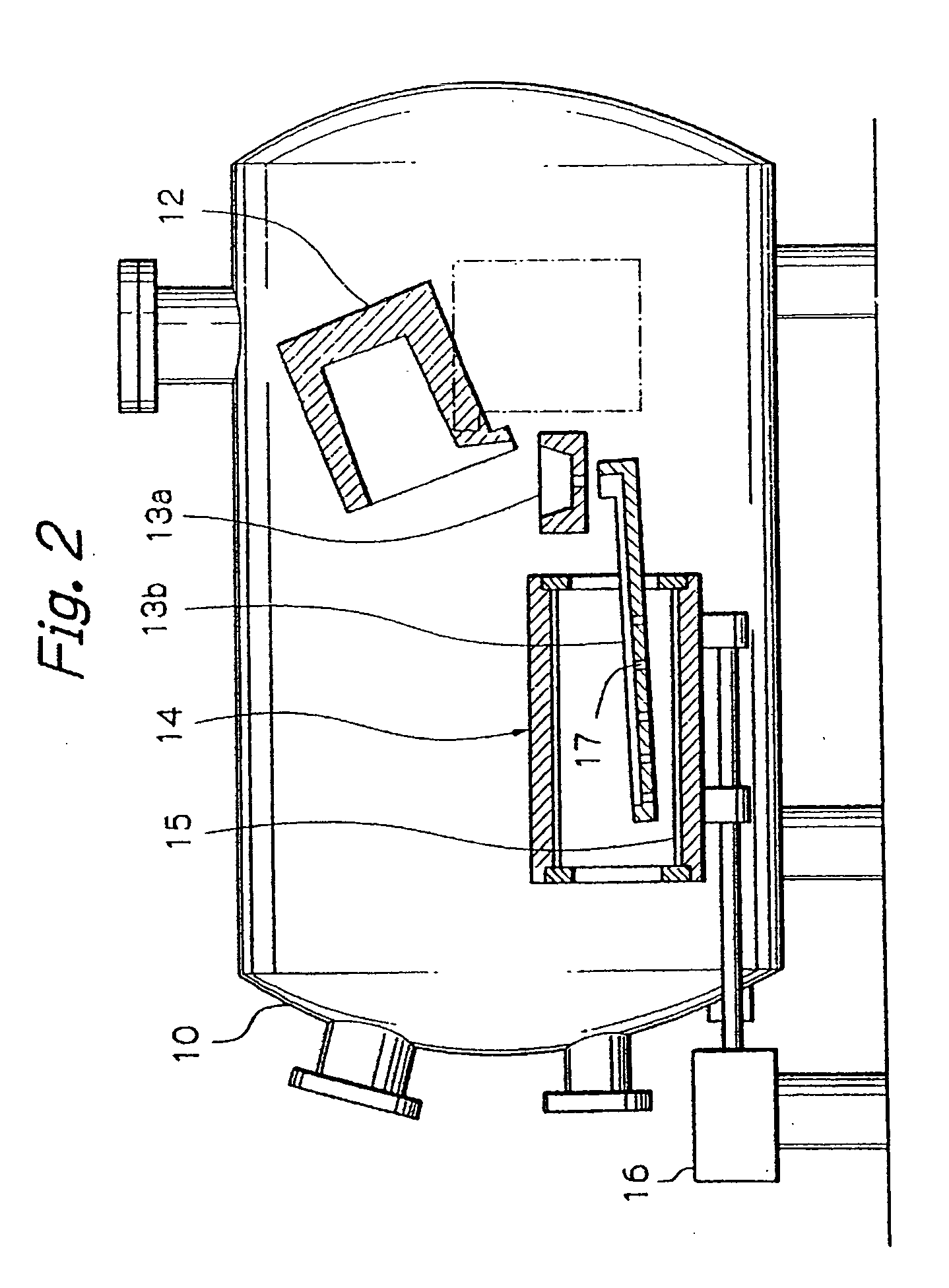

[0069] Alumina, mullite and silica were blended to provide the refractory construction as described in Table 1. A binder in 15 weight parts was blended to 100 weight parts of the resultant fiber mixture. The fiber mixture and the binder were sufficiently mixed to provide a slurry mixture. It was then shaped by a press machine into material in the form of a trough-shaped tundish. After hardening by natural drying, heat treatment was carried out at the heat-treating temperature shown in Table 1. The tundish 1 has a shape shown in FIG. 3. The dimension of the respective parts was: 360 mm of width (w), 125 mm of height (h), 900 mm of length (l), 100 mm of depth of the melt-flowing portion (h1), 310 mm of the upper width (w1), and 300 mm of the bottom width (w2).

[0070] In Table 1 are shown the chemical analysis results of Al2O3 and SiO2, bulk density, and the maximum thermal conductivity at 1200 to 1400° C. In addition, a sample was taken from the tundish and was ignited at 1400° C. for...

example 2

[0075] A tundish consisting of the same refractory material as in Example 1 was used in the same strip-casting method as in Example 1 to cast a Mm (misch metal) Ni-based alloy (1450° C. of tapping temperature). The melt flowed normally on the tundish without solidifying on the tundish. The flowing coefficient at this time was 0.67.

[0076] When the condition of the tundish was examined after completion of casting, neither discoloring nor foreign matters suggesting its reaction with the melt, were recognized.

example 3

[0077] A tundish consisting of the same refractory material as in Example 1 was used in the same strip-casting method as in Example 1 to cast an Sm Co-based alloy (1450° C. of tapping temperature). The melt flowed normally on the tundish without solidifying on the tundish. The flowing coefficient at this time was 0.71.

[0078] When the condition of the tundish was examined after completion of casting, reaction with the melt was not recognized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com