Cooling-assisted, heat-generating electrical component and method of manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

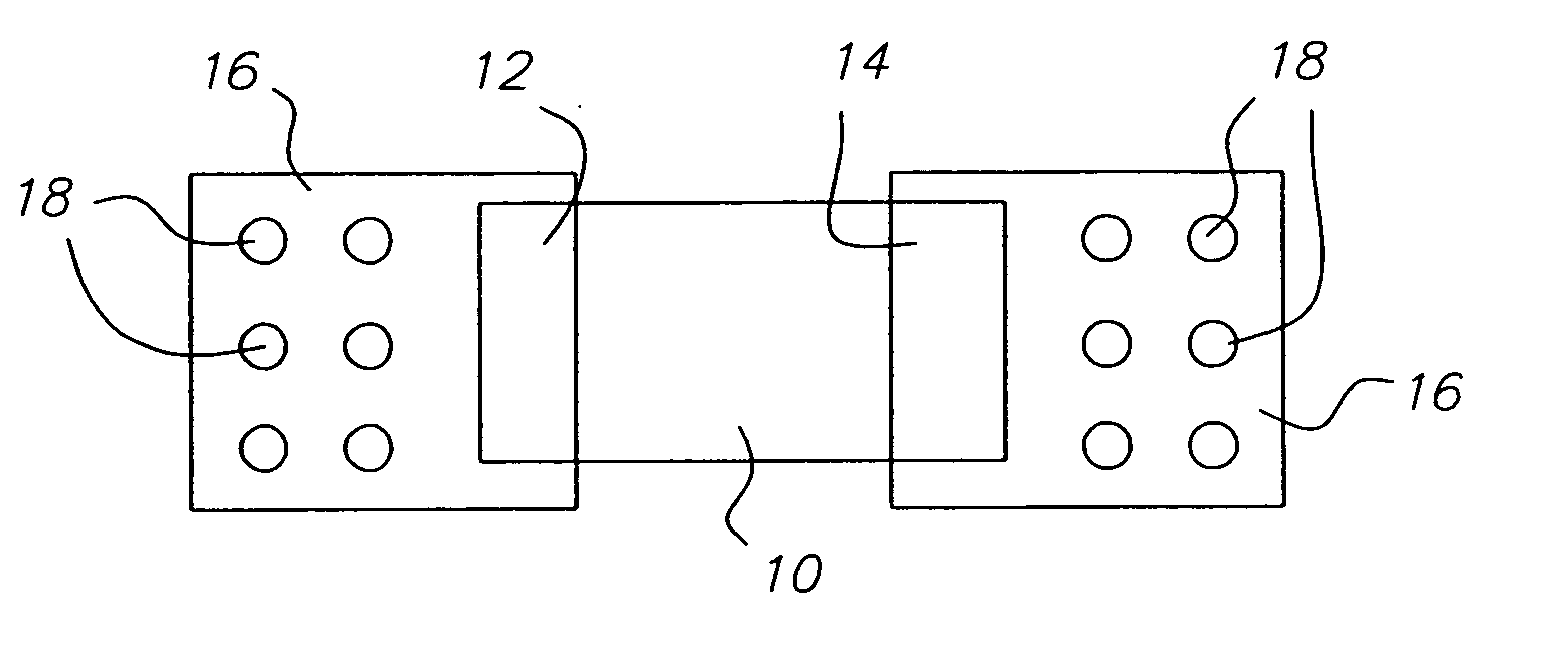

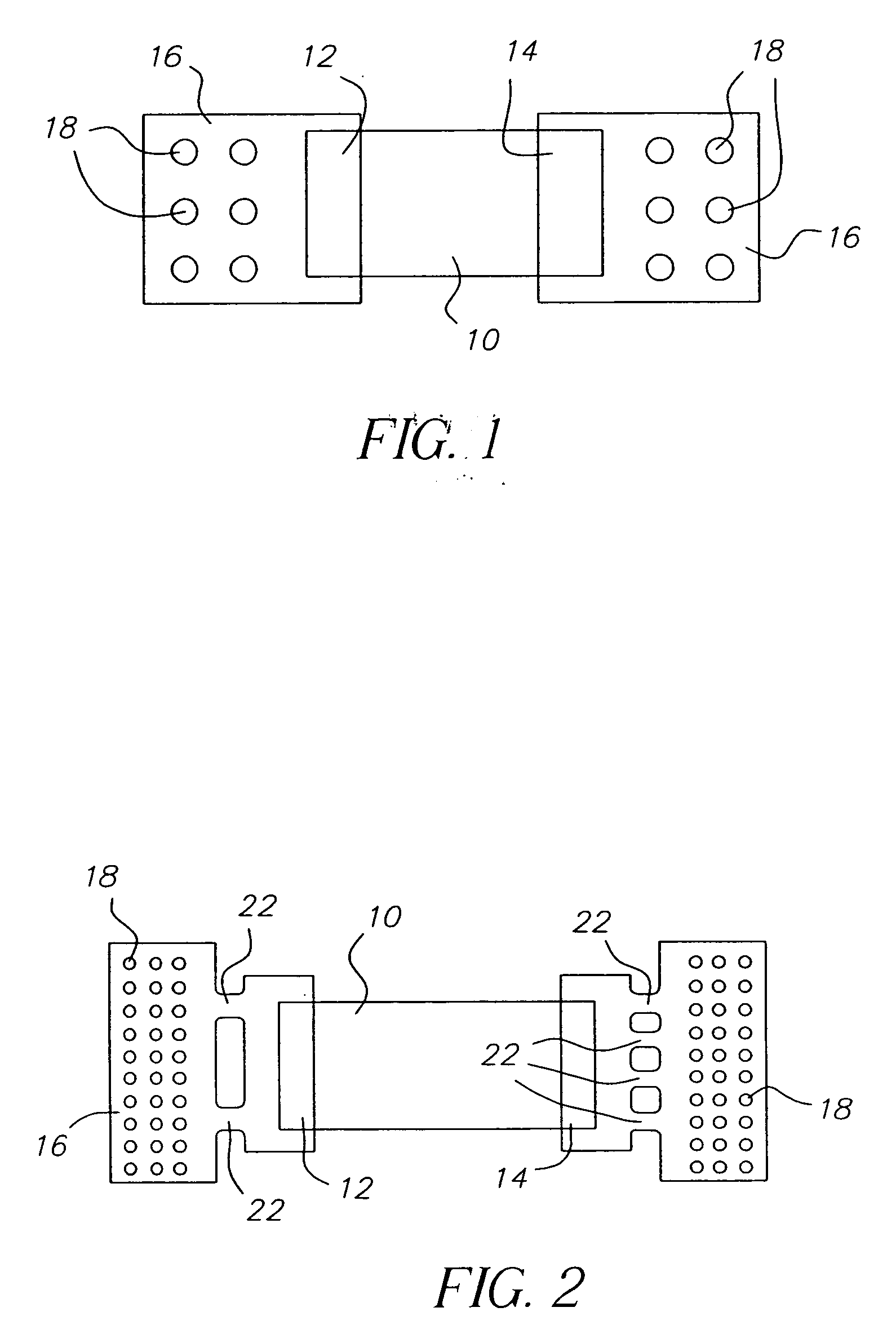

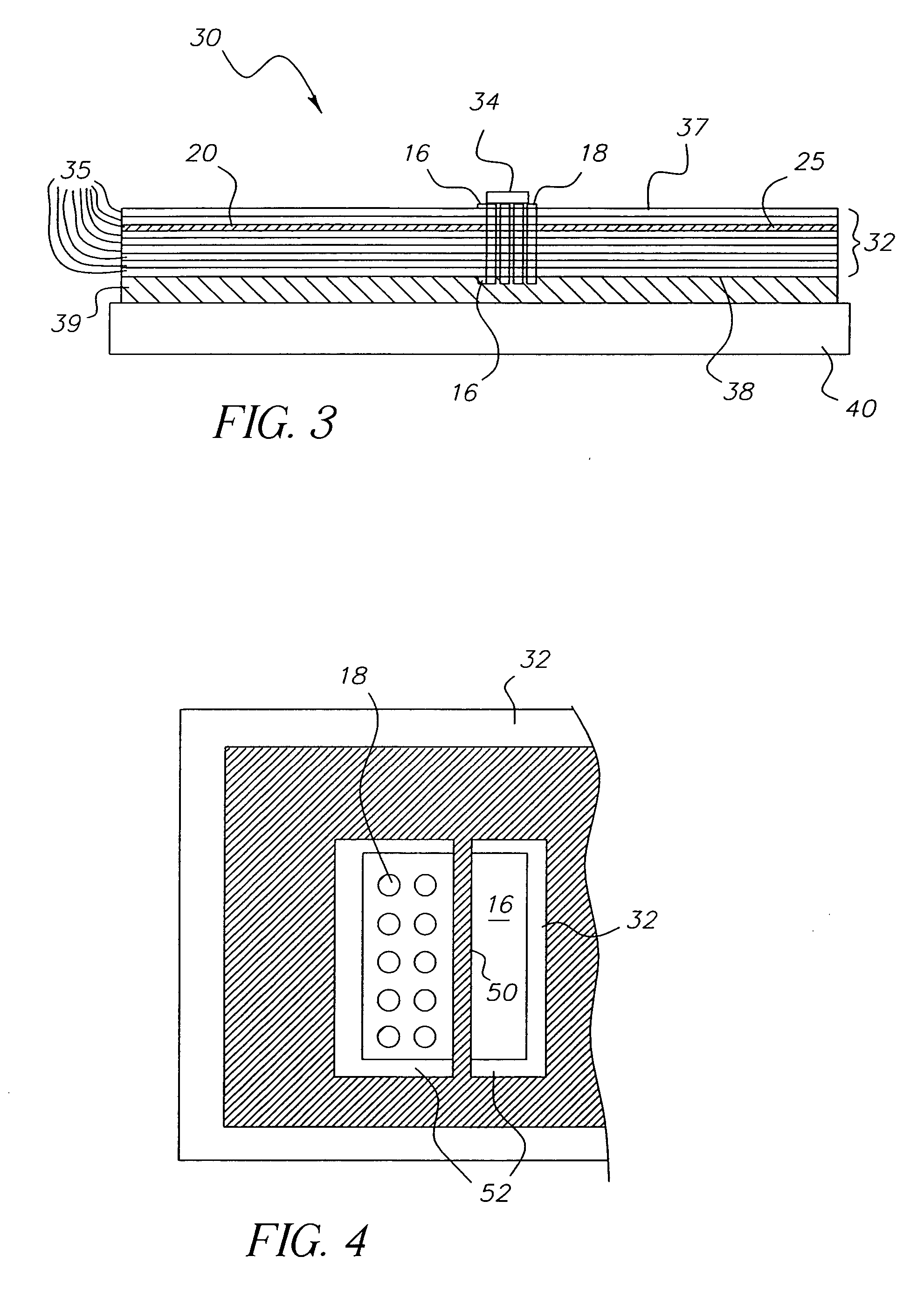

[0017] Turning now to the drawings, and in particular to FIGS. 1 and 2, the electrical component 10 of the invention is illustrated. According to FIG. 1, electrical component 10, for instance a resistor or capacitor, has mating portions 12, 14 and a heat-removing element 16 attached to either of mating portions 12, 14. Electrical component 10 is preferably made of a ceramic or ceramic-like material for suitability of die usage or affixing other electrical components (multi-chip module). Although soldering is the preferred method of attaching heat-removing element 16 to either of mating portions 12, 14, skilled artisans will appreciate that other methods may be used including using electrically conductive adhesives. Mating portions 12, 14 are typically gold or palladium tipped for best thermal conductivity and solderability. Skilled artisans will appreciate that, alternatively, the mating portions 12, 14 may comprise other thermally conductive materials such as tin-lead.

[0018] Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com