Method and apparatus for plating substrates

a substrate and plating technology, applied in the direction of electrolysis components, coatings, liquid/solution decomposition chemical coatings, etc., can solve the problem of substrate wobble, and achieve the effect of reducing the amount of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

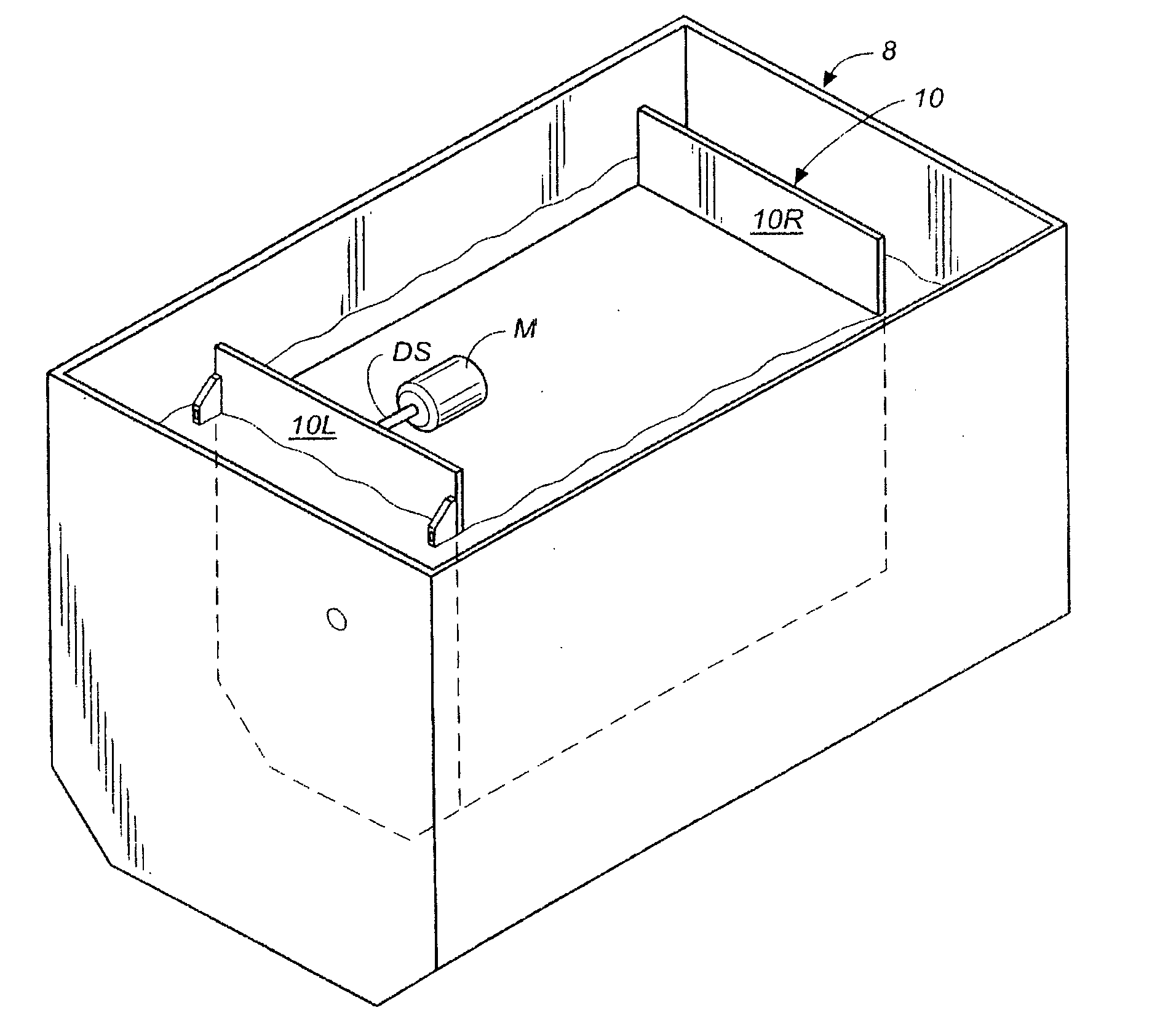

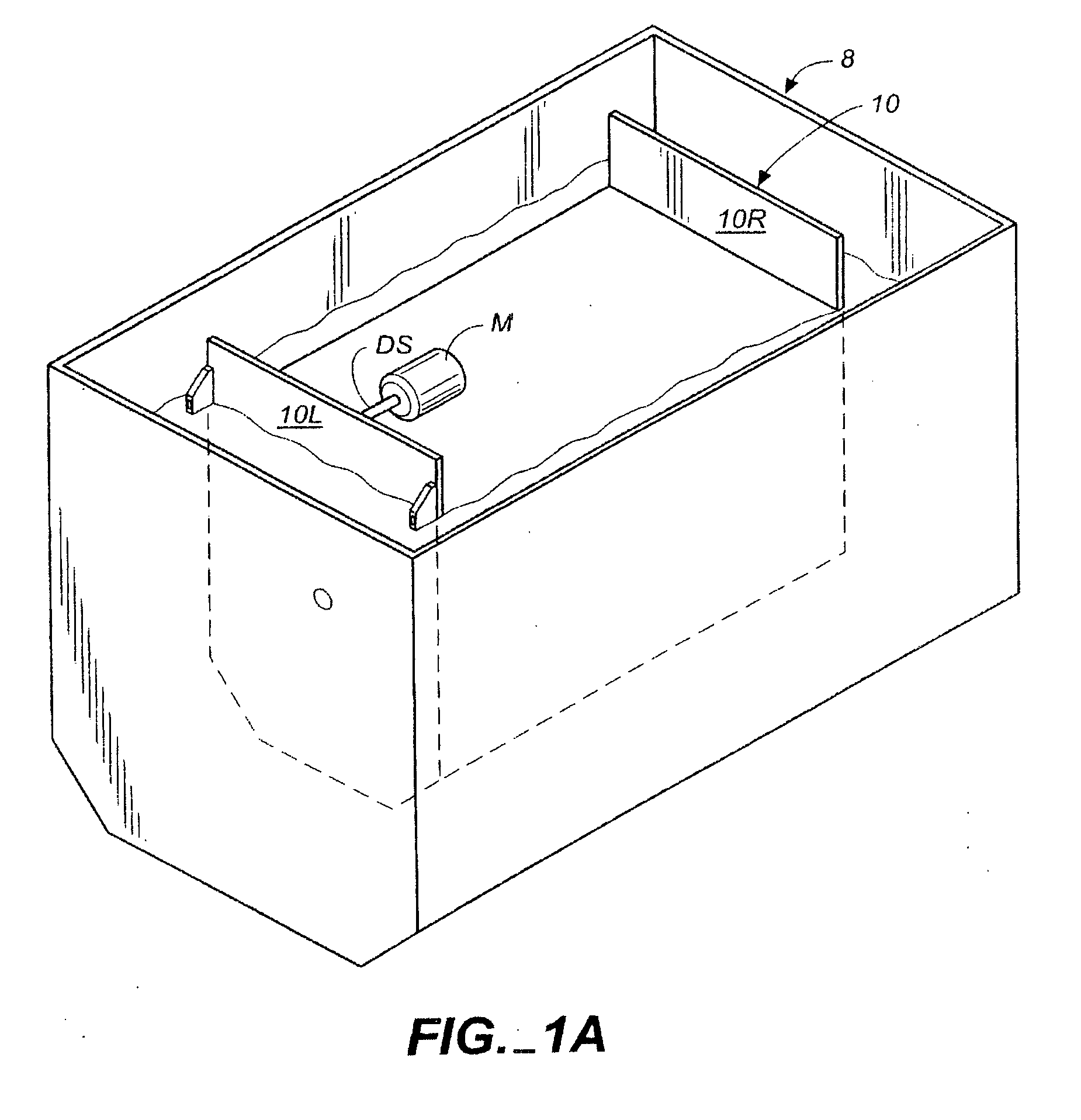

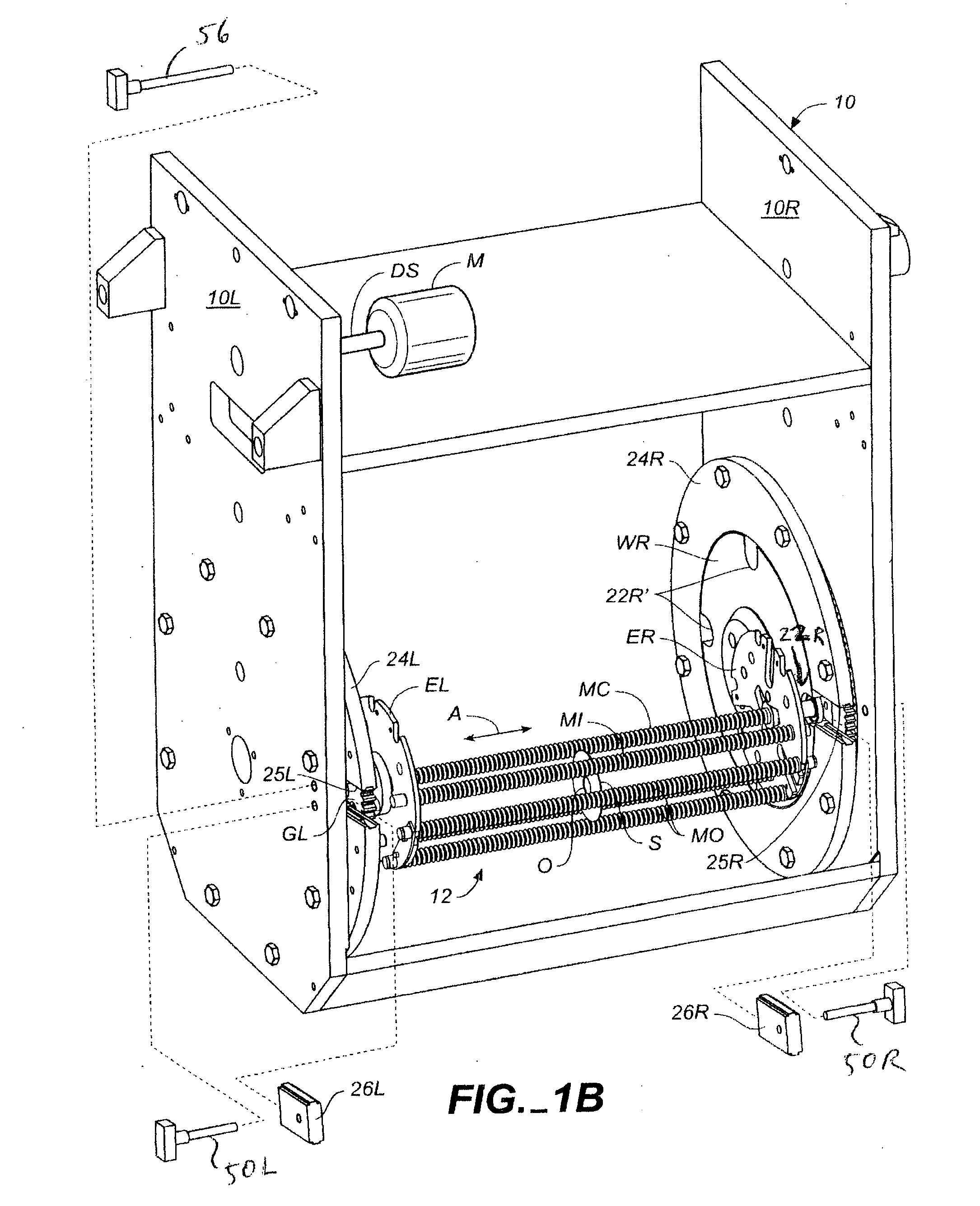

[0028] Referring to FIGS. 1 and 5, a plating bath 8 contains apparatus 10 for holding and moving substrates S during a plating process. (FIGS. 1B and 1C only show one substrate S. However, typically many substrates are plated simultaneously.) In one embodiment, the substrates comprise an aluminum alloy, and during plating, a layer (typically a metallic layer such as a nickel-phosphorus alloy) is deposited on substrates S. However, in other embodiments, substrates S can comprise other materials, and other types of layers can plated onto substrates S.

[0029] In one embodiment, substrates S are disk-shaped, and can include a centrally defined opening O therein. However, in other embodiments, substrates S have other shapes.

[0030] The plating process can be electroless plating or electroplating. Optionally, in the case of electroless plating one can apply a strike voltage to substrates S to facilitate initiation of plating. Alternatively, in some embodiments, a strike voltage is not app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical | aaaaa | aaaaa |

| mechanical interface | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com