Fiber-cement/gypsum laminate composite building material

a fiber cement and gypsum technology, applied in the direction of building components, sustainable waste treatment, solid waste management, etc., can solve the problems of poor abuse resistance of gypsum compared to other wallboard materials, easy damage to the paper surface of gypsum wallboard, and typical wall abuse, etc., to achieve good abuse resistance and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Field of the Invention

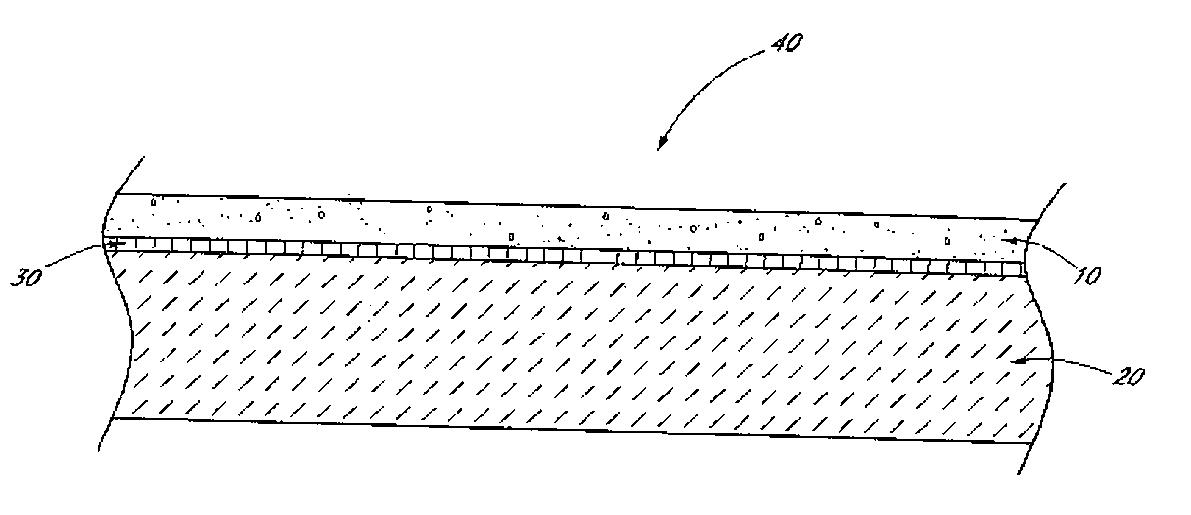

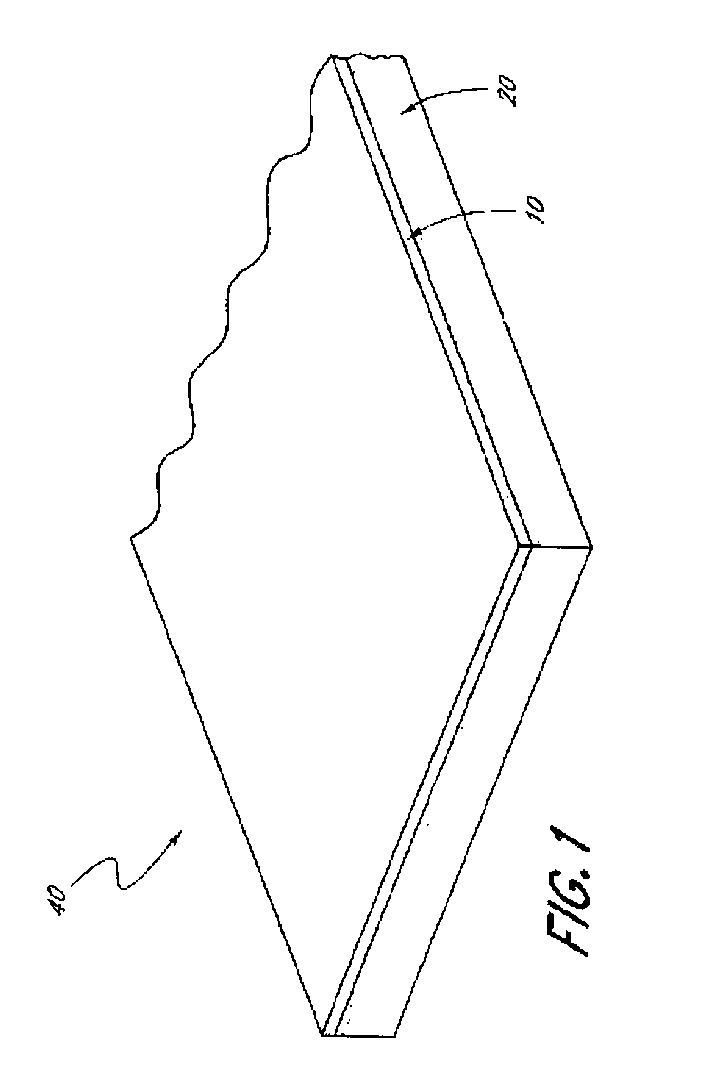

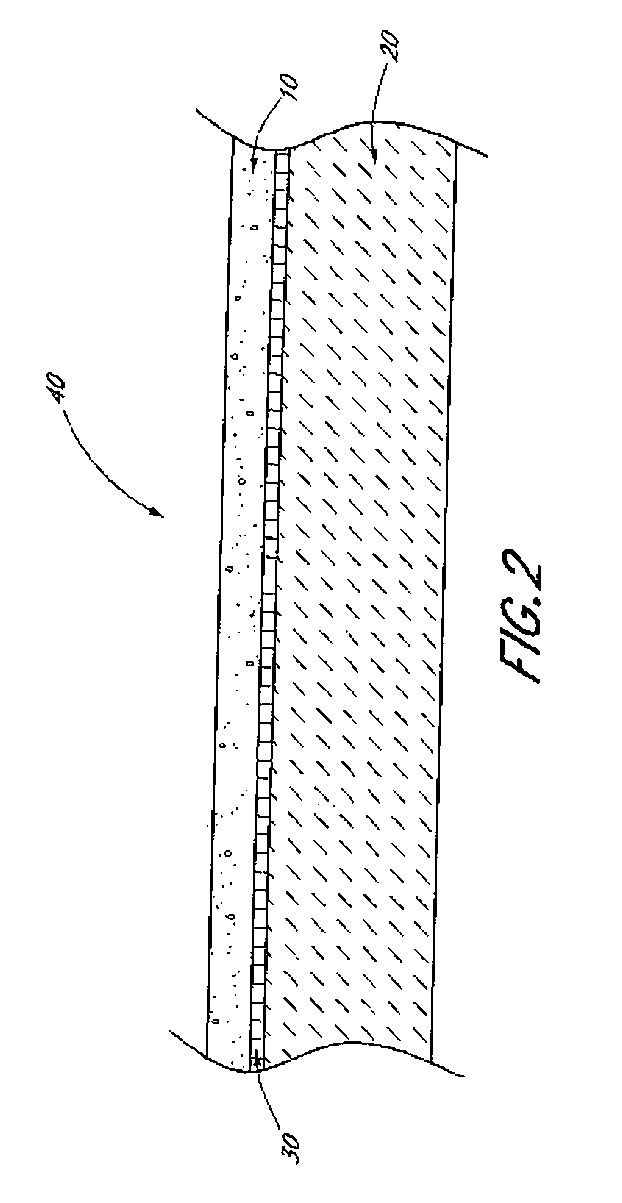

[0001] This invention relates to abuse resistant, impact resistant and fire resistant building materials, and more particularly, to a single piece laminate composite building material of fiber-cement and gypsum.

Description of the Related Art

[0002] The interior wallboard market has been dominated by the use of gypsum wallboard products for many years. The gypsum wallboard typically comprises thin paper layers wrapped around a gypsum core. For example, one paper layer covers the face and long edges of the board, and the second paper layer usually covers the back surface of the board. The core is predominantly gypsum, and can be modified with additives such as glass fiber, vermiculite and mica to improve fire resistance.

[0003] In addition to fire resistance, abuse resistance is another desired quality in wallboards. Gypsum has poor abuse resistance compared to other wallboard materials such as wood or masonry. The paper surface of gypsum wallboard is easily...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com