Stabilizers for polymerizable biocompatible materials

a biocompatible material, stabilizer technology, applied in the direction of plastic/resin/waxes insulators, impression caps, dental prosthetics, etc., can solve the problems of premature polymerization, metal salts, ascorbates, etc., to increase the flexibility of the final product and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0051] An L-cysteine salt solution was prepared and sprayed onto two batches of untreated fillers. One batch was then silanated and mixed with resin to form a stabilized paste; the other batch was mixed directly (without silanation) with resin to form a stabilized paste.

example 3

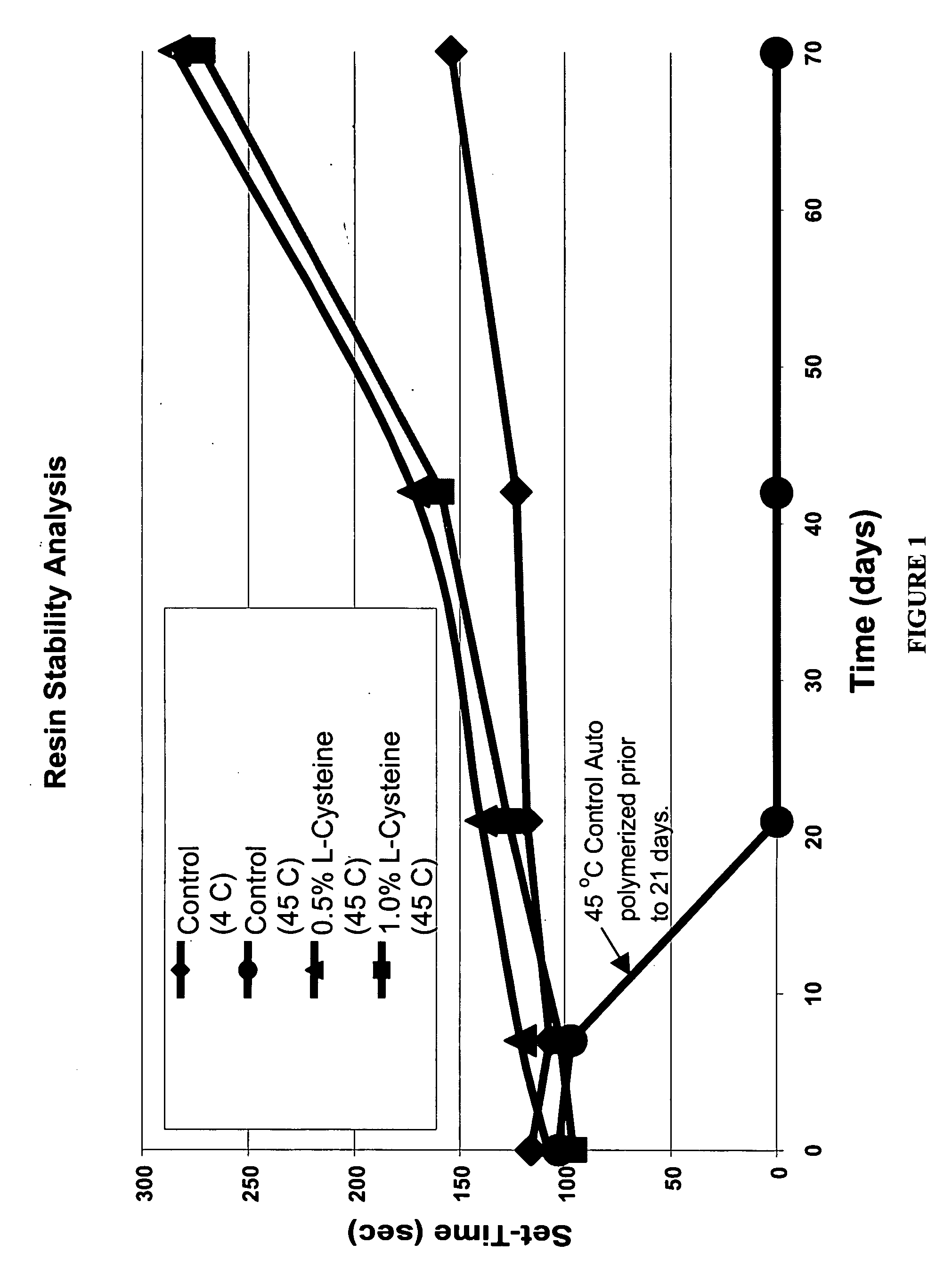

[0052] 1% and 0.5% of L-cysteine stabilizer was added to A resin. Control resin without the addition of stabilizer was also prepared. Set-time and temperature upon cure were measured at time, t=0, t=10 days, t=45 days, and t=70 days for both the stabilized materials and the control. Results indicate that the addition of the L-cysteine inhibited auto polymerization of the samples under 45° C. storage as compared to control samples—one of which polymerized after 20 days (FIG. 1). In addition, the L-cysteine containing samples did not inhibit polymerization upon mixing with a peroxide containing resin. In general, the set-time of the stabilized samples remained below 200 seconds for 50 days when stored at 45° C., which compares favorably to control samples that required refrigeration to achieve the same effect.

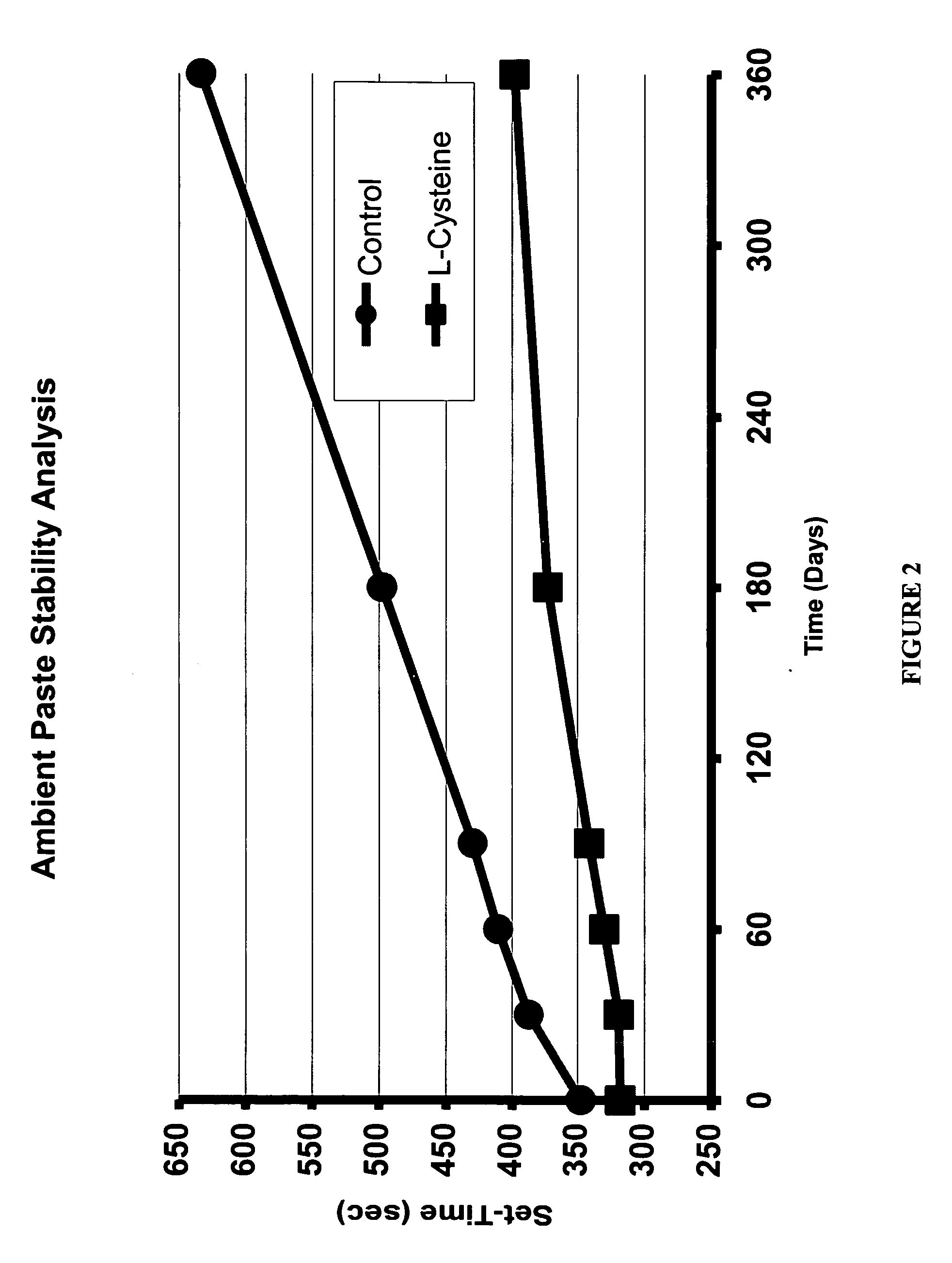

[0053] B) The utilization of stabilized accelerator containing resin in the preparation of composite paste also demonstrated maintenance of the set-time and reaction temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com