Uses of white corn hybrids

a technology of white corn and hybrids, applied in the field of genetics, plant physiology, grain composition, can solve the problems of slow selection progress, difficult mass selection of grain yield improvement, and inability to separate genotype and environment effects using mass selection techniques, so as to improve the yield of critical components, improve the composition, and improve the effect of compositional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0136] This example illustrates the extraction of the substantially pure starch of the present invention from white corn hybrid line 1851W and analyzes the individual components to determine various characteristics. The extraction and analysis of the starch, gluten and fiber components from the present invention (1851W) is summarized in Table 2. Also included in Table 2 is a comparison of the grain analysis of the present invention (1851W) to that of yellow dent corn. The improved variety of the corn of the instant invention, an F1 hybrid, produces grain with higher protein, and extremely low levels of carotenoids. It is also important to note that the 1851W gluten and fiber components have substantially higher protein levels than the yellow corn. In addition, the fiber portion of 1851W has significantly higher protein solubility values than the yellow corn. The extraction process is outlined in a flow diagram in FIG. 1. Analysis of the components presented in Table 2 were completed...

example 2

[0145] This example compares the substantially similar characteristics of the hybrid E8272 with those previously described herein for the hybrid 1852W. The extraction techniques and comparative analysis are summarized below.

[0146] A 1.159 kg sample of E8272 and a 1.158 kg sample of 1851W were wet milled in a laboratory of the Center for Crops Utilization Research, Iowa State University (Ames, Iowa) to obtain high-quality corn starch, gluten meal, fiber and germ. The samples were steeped in 2.5 liters of solution containing 0.5% lactic acid and 0.2% SO2 at 50° C. for 40 hours. The steeped corn was strained and the volume and pH of steep water measured. The steep water was then analyzed for dissolved solids.

[0147] The steeped corn was separated into several 200 gram fractions. Each fraction was ground with 200 ml water in a 1-liter Waring blender equipped with blunted blades and set at 50% speed for 4 minutes. The coarsely ground slurries were combined into a 4-liter bucket. One lit...

example 3

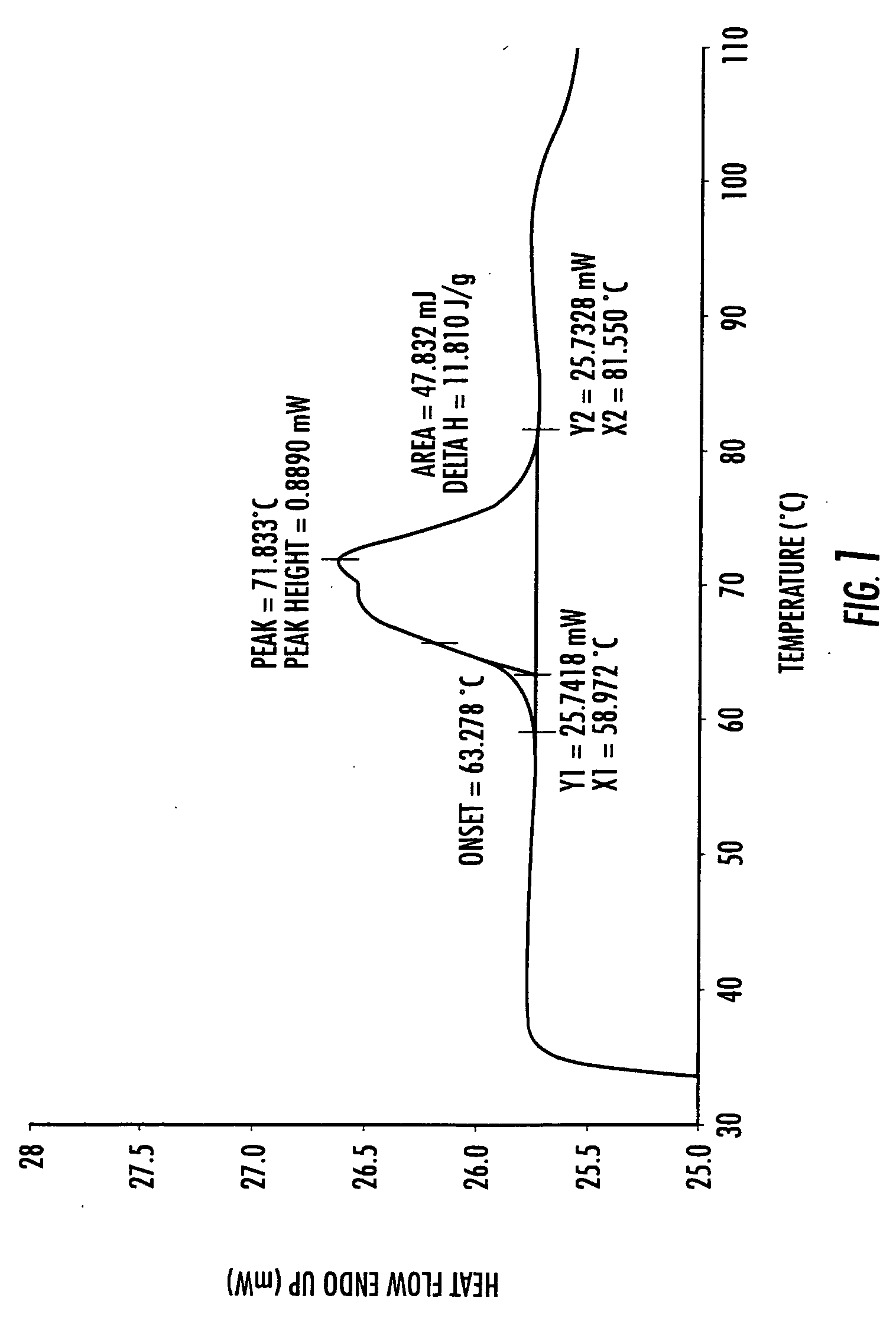

[0160] This example illustrates the uniqueness of the pearl starch of 1851W and how it is positioned in the grain. Susan Duvick, manager of the USDA-ARS Quality Trait Analysis Laboratory looked at the structure and functionality of the starch from the 1851W hybrid that had been milled at the Iowa State University Center for Crops Utilization Research. The starch was gelatinized and stored for a week, then analyzed with differential scanning calorimetry (DSC) to measure how much energy was required to melt the crystallized starch. A typical corn starch generates a single, fairly uniform peak upon the same analysis. The DSC profile for the 1851W starch showed the starch gelled in two phases as shown in FIG. 1.

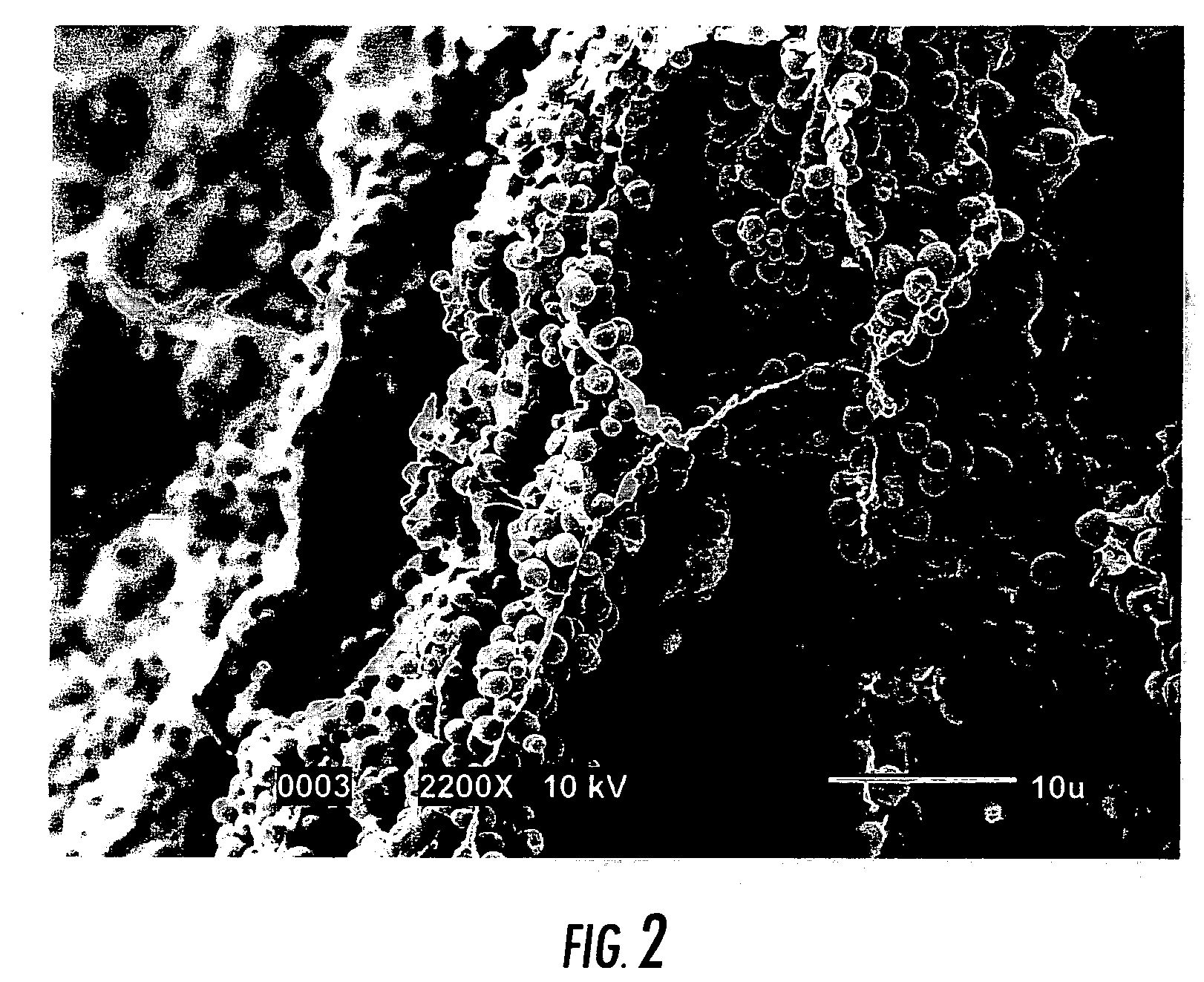

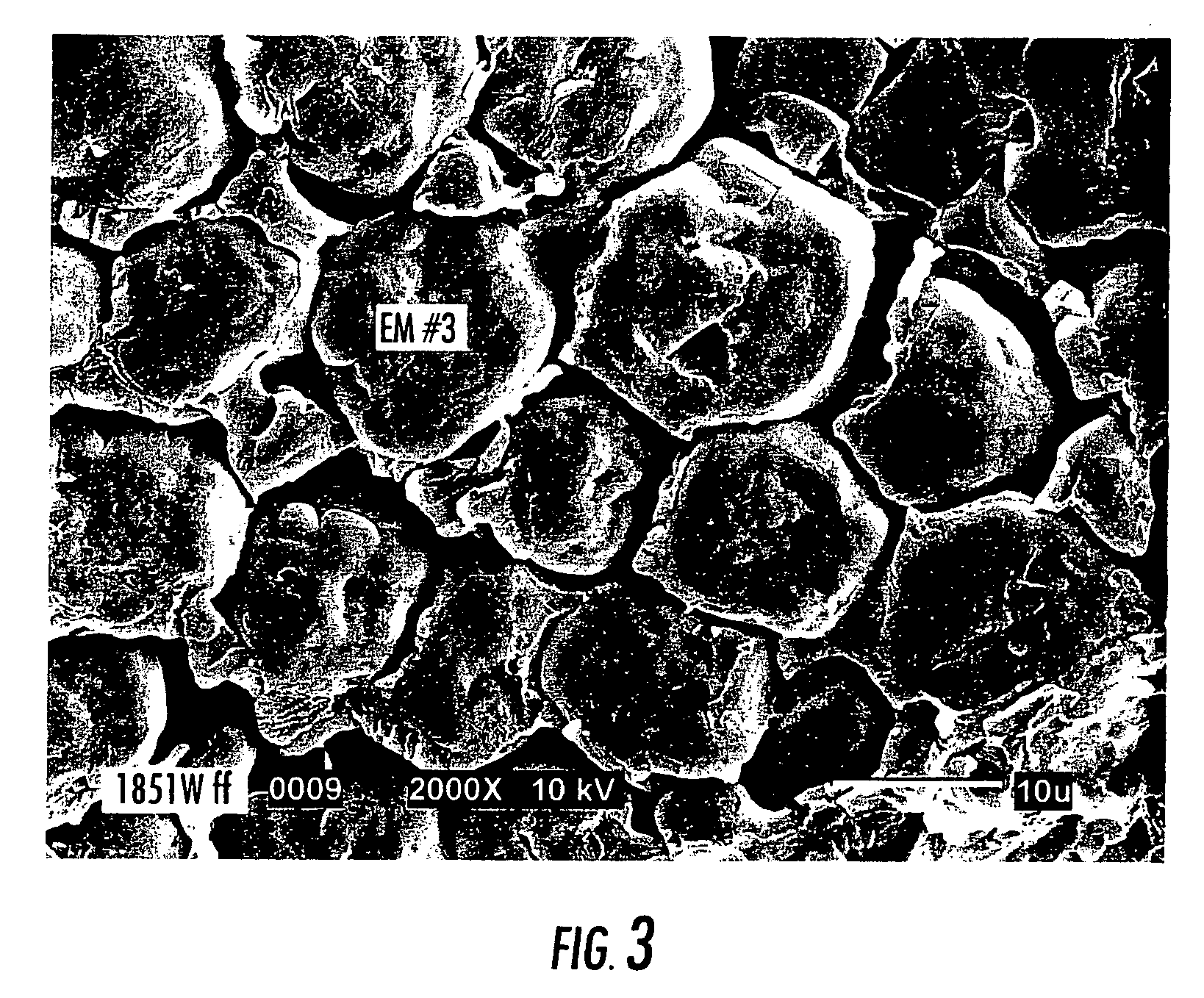

[0161] To account for the two thermal events, the starch granules were studied using electron micrography. A kernel of 1851W was freeze fractured and the starch granules were examined towards the tip and towards the crown of the kernel. Two distinct types of granules were found ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com