Self-similar laser oscillator

a laser oscillator and self-similar technology, applied in the field of lasers, can solve the problems of affecting the performance of the laser, the length of the gain segment is minimized, and the solution cannot meet periodic boundary conditions, so as to achieve the effect of effectively decoupling bandwidth filtering, broadening the bandwidth and reducing the length of the gain segmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

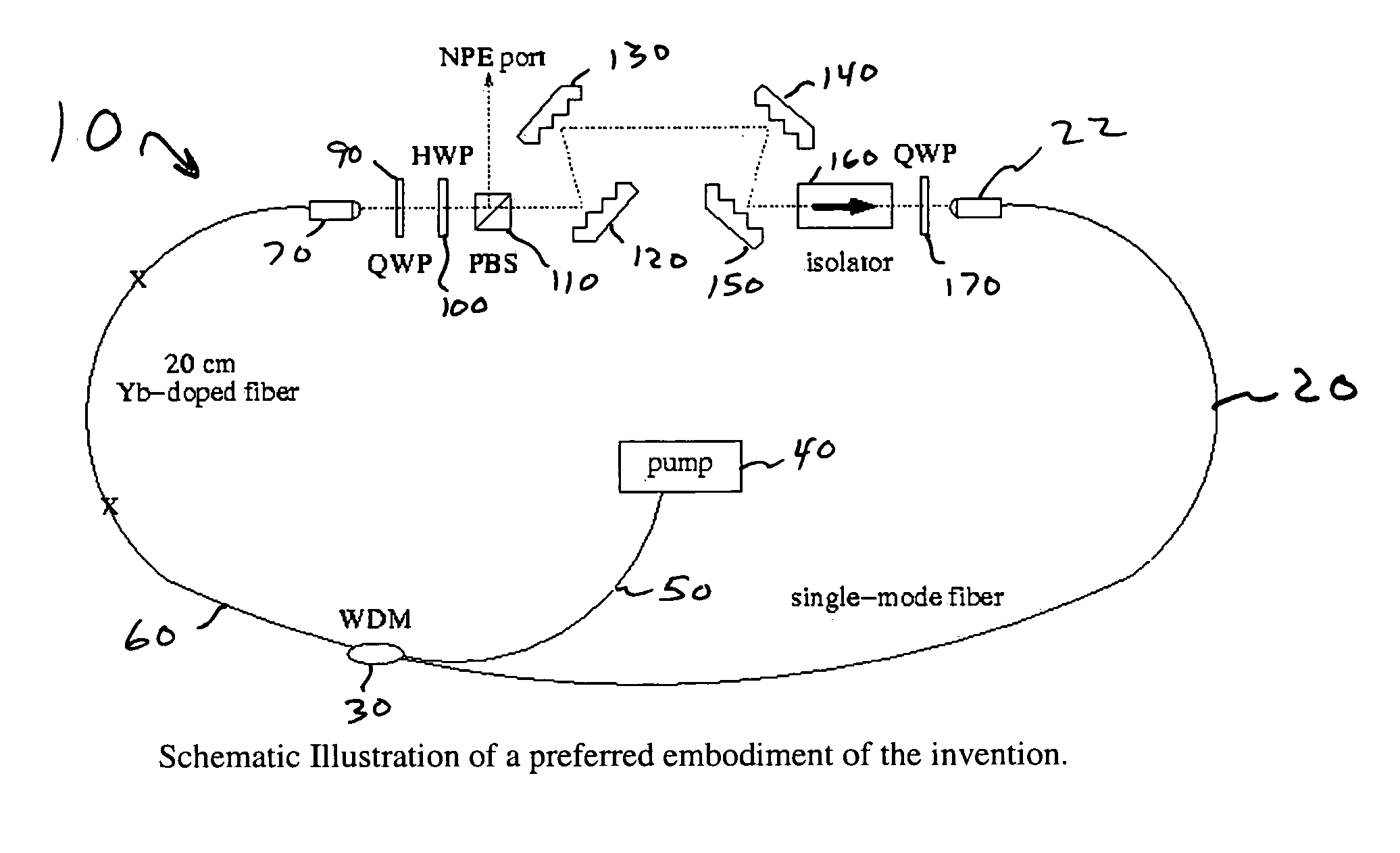

[0053] Referring now to FIG. 2, the fiber laser 10 of the invention is shown as a ring laser. The fiber laser of the invention could also be configured as a figure-eight cavity, linear cavity or other suitable laser geometry, as will be understood by those skilled in the art. The ring geometry described herein is but one example of the many geometries to which the invention could be applied.

[0054] The fiber ring laser of FIG. 2 comprises several segments. On the right side of the ring, we see segment 20 of the ring laser 10 of the invention comprises the majority of the optical length of the cavity and generally supports only a single spatial mode. In a preferred embodiment this segment of fiber single mode fiber (SMF) has a length of 4 meters. Segment 20 is characterized by a net positive group velocity dispersion (also referred to as net normal dispersion). One end of segment 20 is connected a collimator 22 to receive a pulse circulating in the cavity. The other end is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com