Sensor head for use with implantable devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of the Multi-region Membrane

[0110] A. Preparation of the First Region

[0111] The cell disruptive domain may be an ePTFE filtration membrane and the cell impermeable domain may then be coated on this domain layer. The cell impermeable domain was prepared by placing approximately 706 gm of dimethylacetamide (DMAC) into a 3 L stainless steel bowl to which a polycarbonateurethane solution (1325 g, Chronoflex AR 25% solids in DMAC and 5100 cp) and polyvinylpyrrolidone (125 g, Plasdone K-90 D) are added. The bowl was then fitted to a planetary mixer with a paddle type blade and the contents were stirred for 1 hour at room temperature. This solution was then coated on the cell disruptive domain by knife edge drawn at a gap of 0.006″ and dried at 60° C. for 24 hours.

[0112] Alternatively, the polyurethane polyvinylpyrrolidone solution prepared above can be coated onto a PET release liner using a knife over roll coating machine. This material is then dried at 305° F. for approx...

example 2

In vitro Evaluation of Sensor Devices

[0121] This example describes experiments directed at sensor function of several sensor devices contemplated by the present invention.

[0122] In vitro testing of the sensor devices was accomplished in a manner similar to that previously described. [Gilligan et al., Diabetes Care 17:882-887 (1994)]. Briefly, devices were powered on and placed into a polyethylene container containing phosphate buffer (450 ml, pH 7.30) at 37° C. The container was placed onto a shaker (Lab Line Rotator, model 1314) set to speed 2. The sensors were allowed to equilibrate for at least 30 minutes and their output value recorded. After this time, a glucose solution (9.2 ml of 100 mg / ml glucose in buffer) was added in order to raise the glucose concentration to 200 mg / dl within the container. The sensors were allowed to equilibrate for at least 30 minutes and their output value recorded. Again, a glucose solution (9.4 ml of 100 mg / ml glucose in buffer) was added in orde...

example 3

The Effect of Varying the Size and Material of the Counter Electrode on Sensor Response and Accuracy

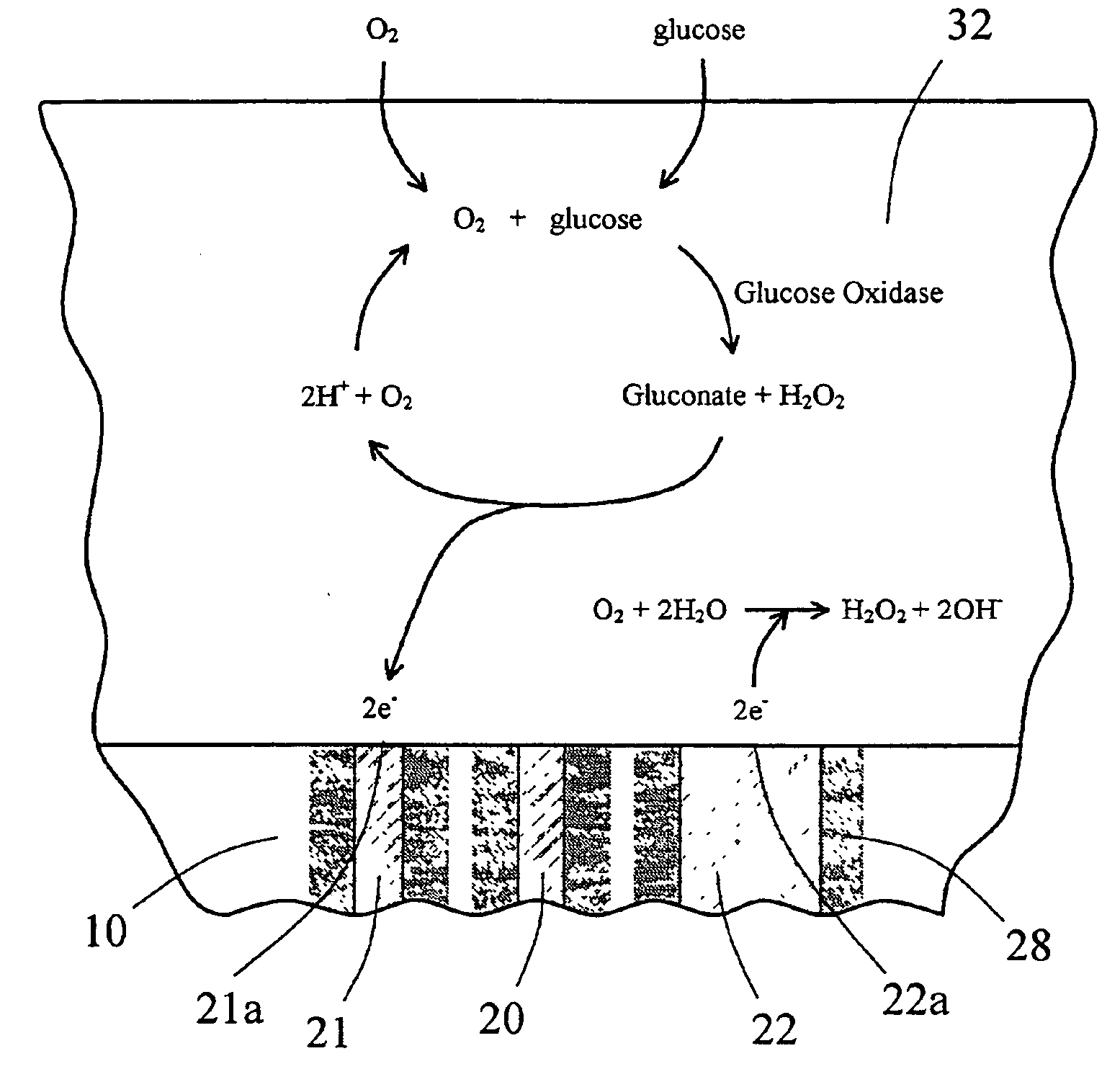

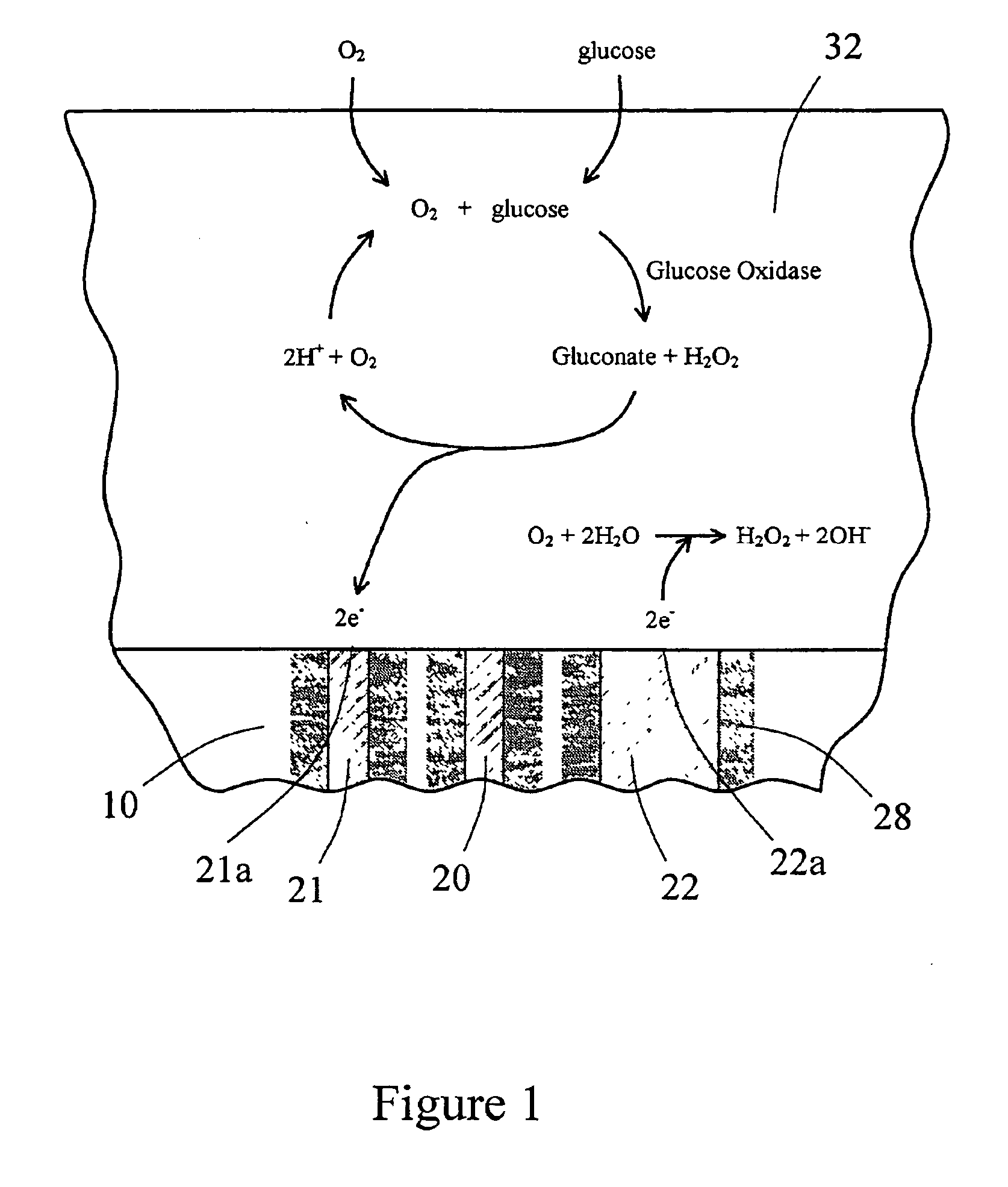

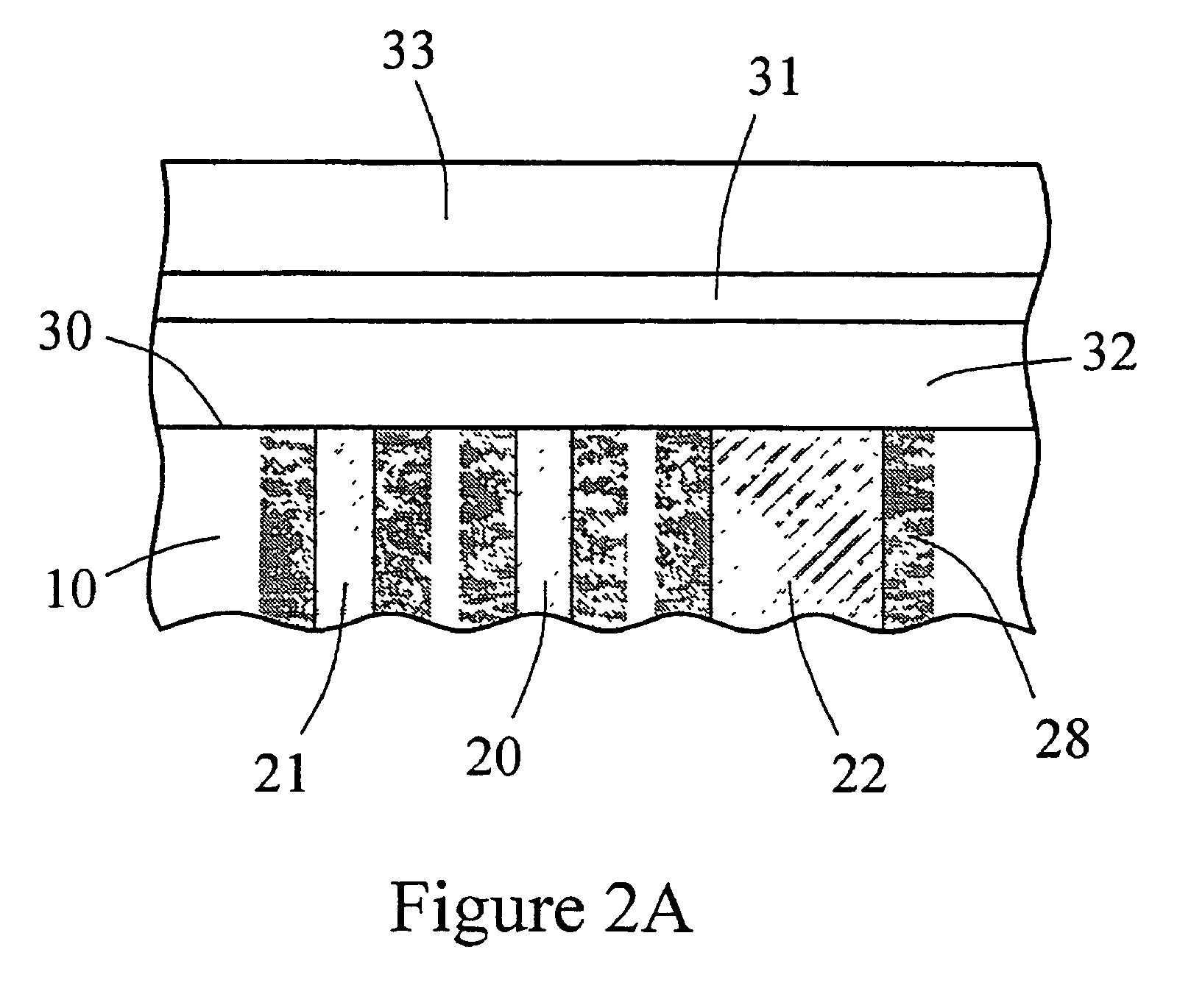

[0127] An in vitro testing procedure used in this example was similar to that described in Example 2. Six devices similar to the one shown in FIG. 6A and 6B were fitted with the multi-region membrane described herein. Two of these tested devices were comparative devices that possessed Pt counter electrodes having a 0.020″ diameter; this diameter provided for an electrochemically reactive surface of the counter electrode which was substantially equal to the surface area of the working electrode, as schematically shown in FIG. 8. In FIG. 8, the electrode-membrane region includes two distinct regions, the compositions and functions of which have already been described. Region 32 includes an immobilized enzyme. Region 33 includes a cell disruptive domain and a cell impermeable domain. The top ends of electrodes 21 (working), 20 (reference) and 22 (counter) are in contact with an electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com