Product and method for protecting metal during etching

a technology of metal etching and product, applied in the field of product and process for protecting metals during etching, can solve the problems of inability to accurately texturize the area, the existing method of masking portions of the internal surface of the mold has significant limitations, and the image quality can easily be degraded during transfer, so as to improve the etching of the interior surface, and improve the effect of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

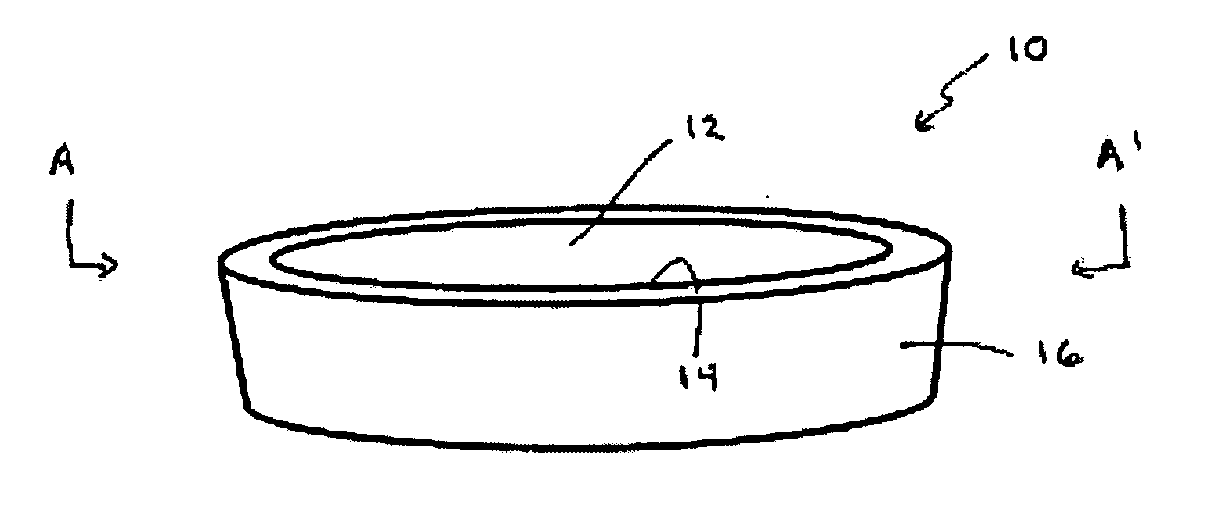

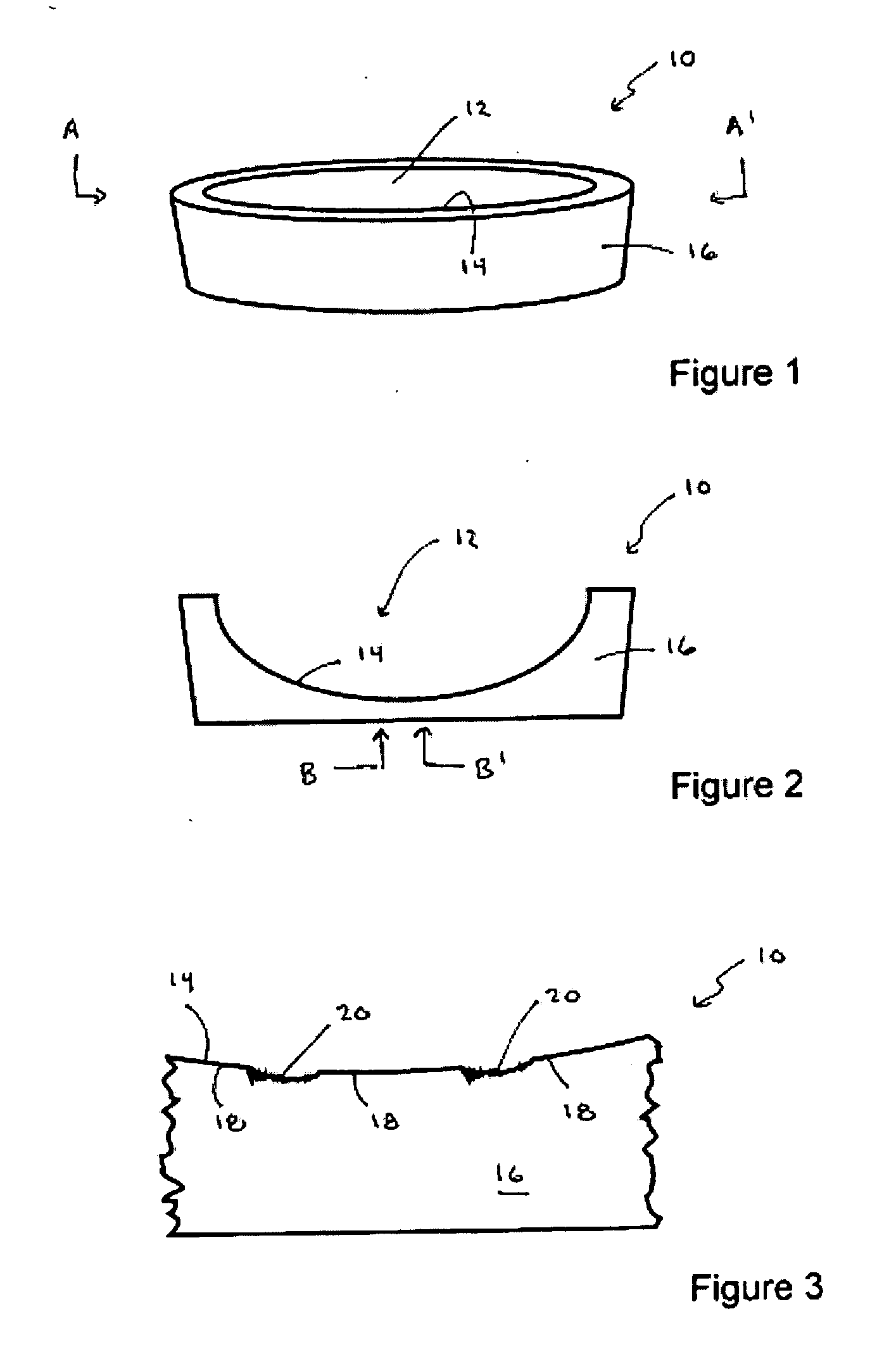

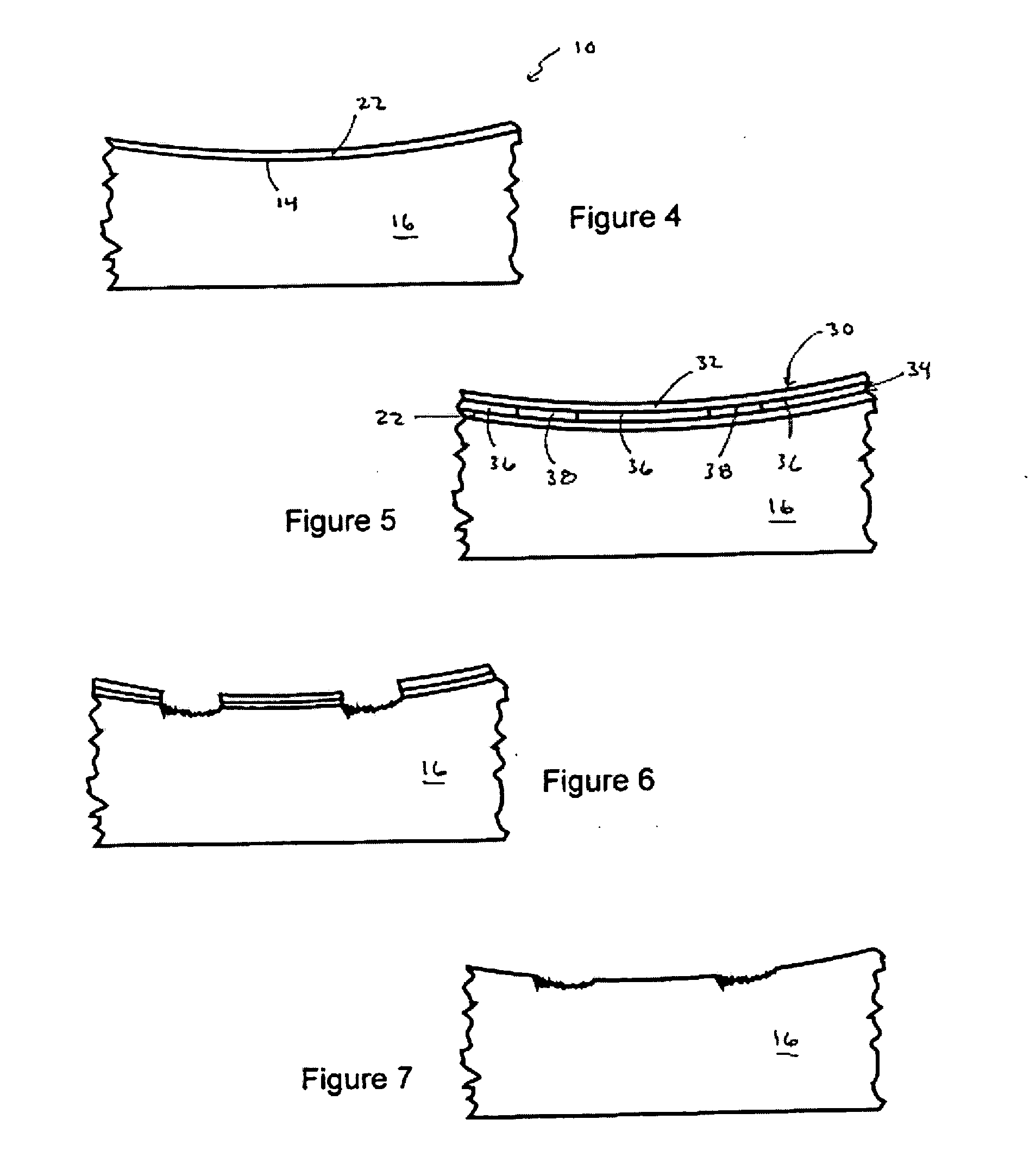

[0022] The present invention is directed, in general, to coating the interior of a mold with a material that will resist etchant, and then selectively removing the etchant to create a desirable pattern in the mold. If the etchant is strong acid, then the etchant-resistnat coating on the interior of the mold should be resistant to strong acids. After the interior of the mold has been coated, parts of the coated area are masked. These masked areas generally correspond to areas of the mold that are not to be etched.

[0023] Suitable masks include, for example, developed photosensitive films, laser cut adhesive films, manually cut films to which an adhesive has been added, printed abrasive resistant material (printed by inkjet, screen printing, etc.) and plastic or rubber stencils configured to be repeatedly used. After the mask has been applied to the interior of the mold, the non-masked portions of the coated interior are removed.

[0024] In one implementation the non-masked portions of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| stretchable | aaaaa | aaaaa |

| stretchability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com