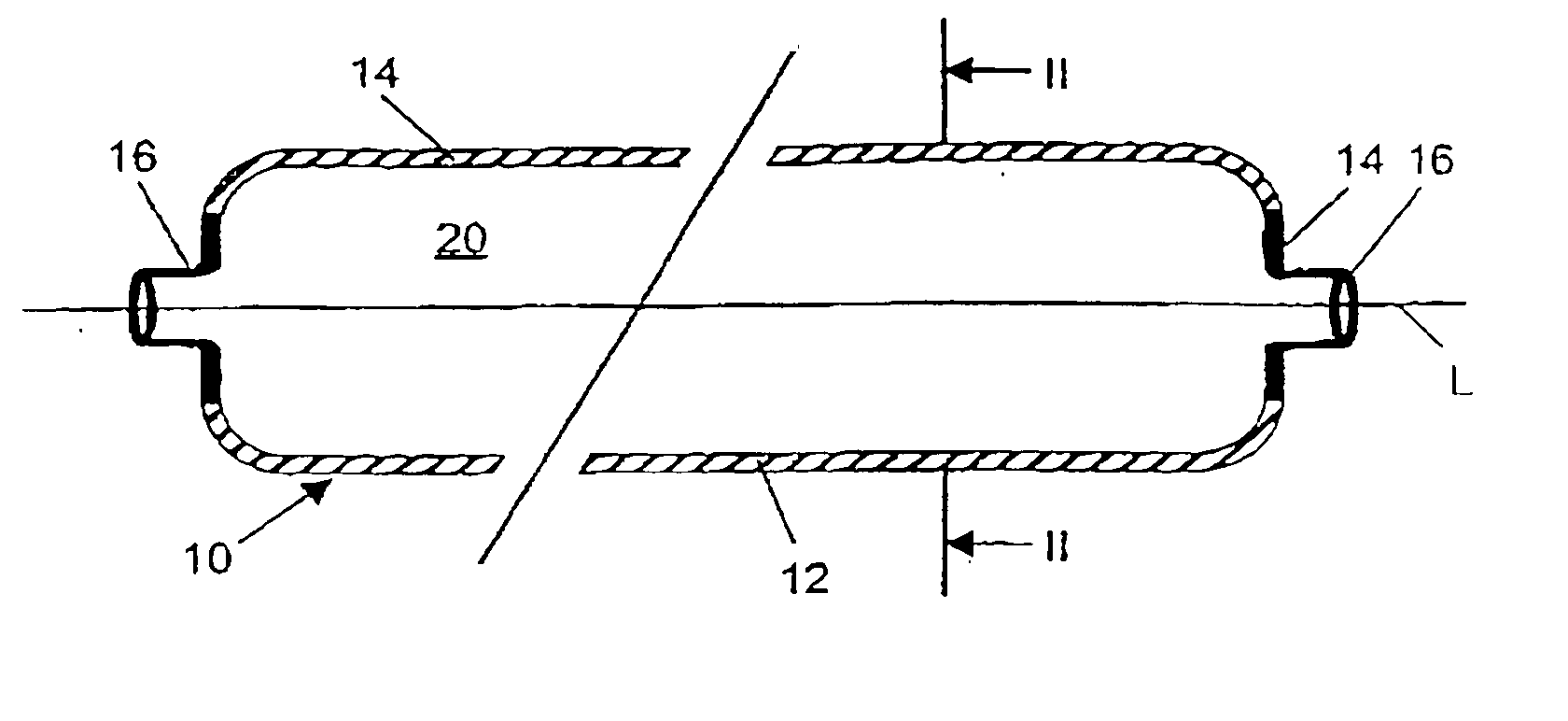

Gastight container

a technology for transport containers and gastight containers, applied in the direction of containers, rigid containers, gas/liquid distribution and storage, etc., can solve the problems of double-walled steel cylinders, high labor intensity, and inconvenient storage of contents, so as to achieve the effect of avoiding the effect of double-walled pressure vessels and vacuum between the two walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

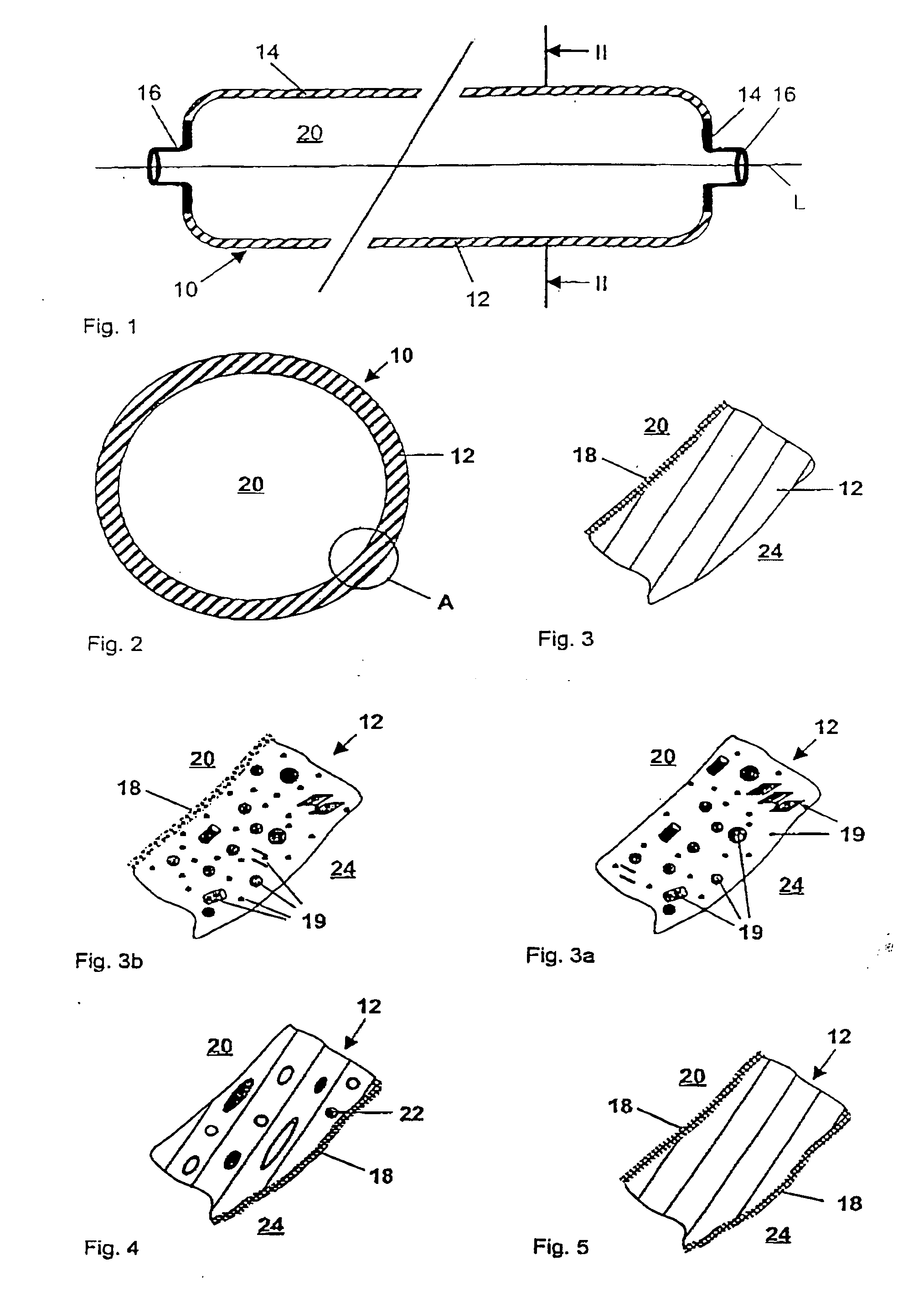

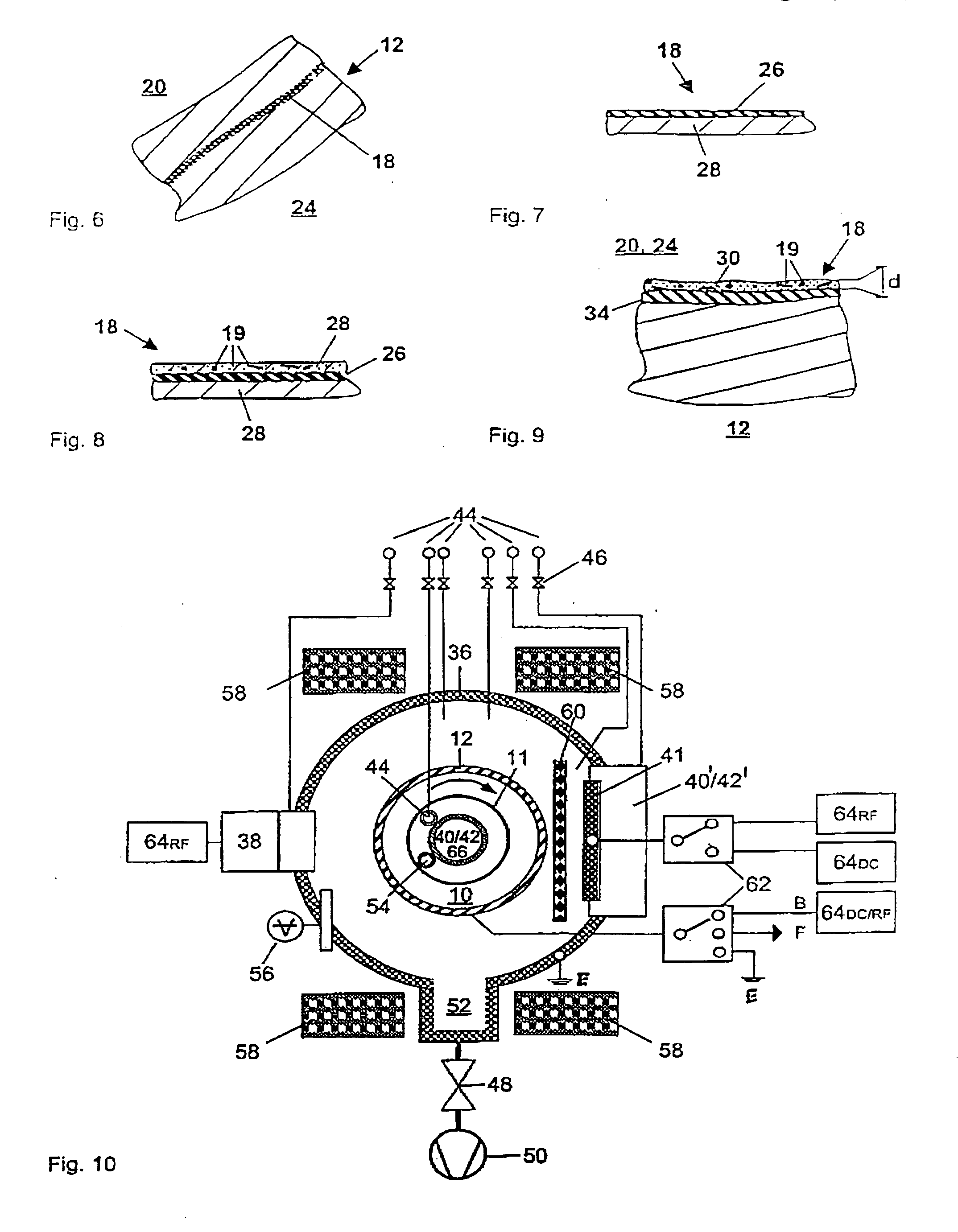

[0034] A plasma coating as a pre-treatment is carried out with a mixture of equal parts of: Ar, C.sub.2H.sub.2, N.sub.2 and CO.sub.2. This gives a surface tension of >60 mN / m.

[0035] An apolar diffusion barrier layer, i.e. having a barrier effect, can also be applied directly i.e. without pre-treatment by means of plasma polymerisation, for example as an 0.01 to 1 .mu.m thick amorphous DLC hydrocarbon layer (diamond like carbon). This is constructed on the basis of carbon and hydrogen, has a 20 to 80 at % content of the two elements and respectively 0.01 to 6 at % of at least one element of the group comprising oxygen, nitrogen, fluorine, chlorine, bromine, boron and silicon. In this connection reference is made to WO 00 / 32938 (table, item E).

[0036] Following the pre-treatment described above, an actual diffusion barrier layer e.g. a metallic, organic metal-containing and / or ceramic layer is deposited. In the sense of the present invention, the metallic layers also include boron and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com