Sock

a technology for socks and socks, applied in the field of socks, can solve the problems of increasing the amount of manual operator time, affecting the wearer's comfort, and causing bunching, twisting and other causes of discomfort, so as to minimise the overall bulk and weight of the double layer structure, and allow maximum flexibility in the composition and structure of yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

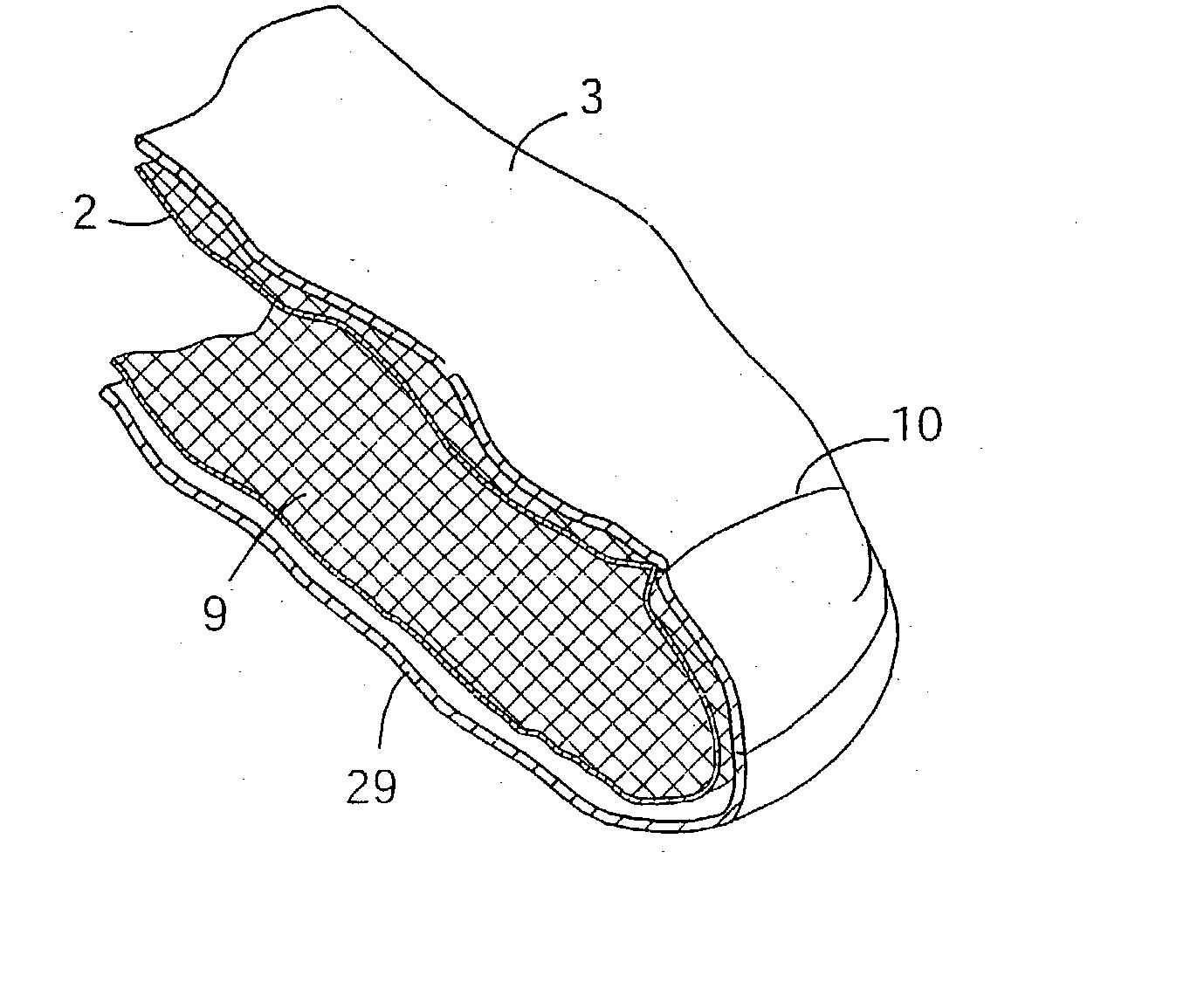

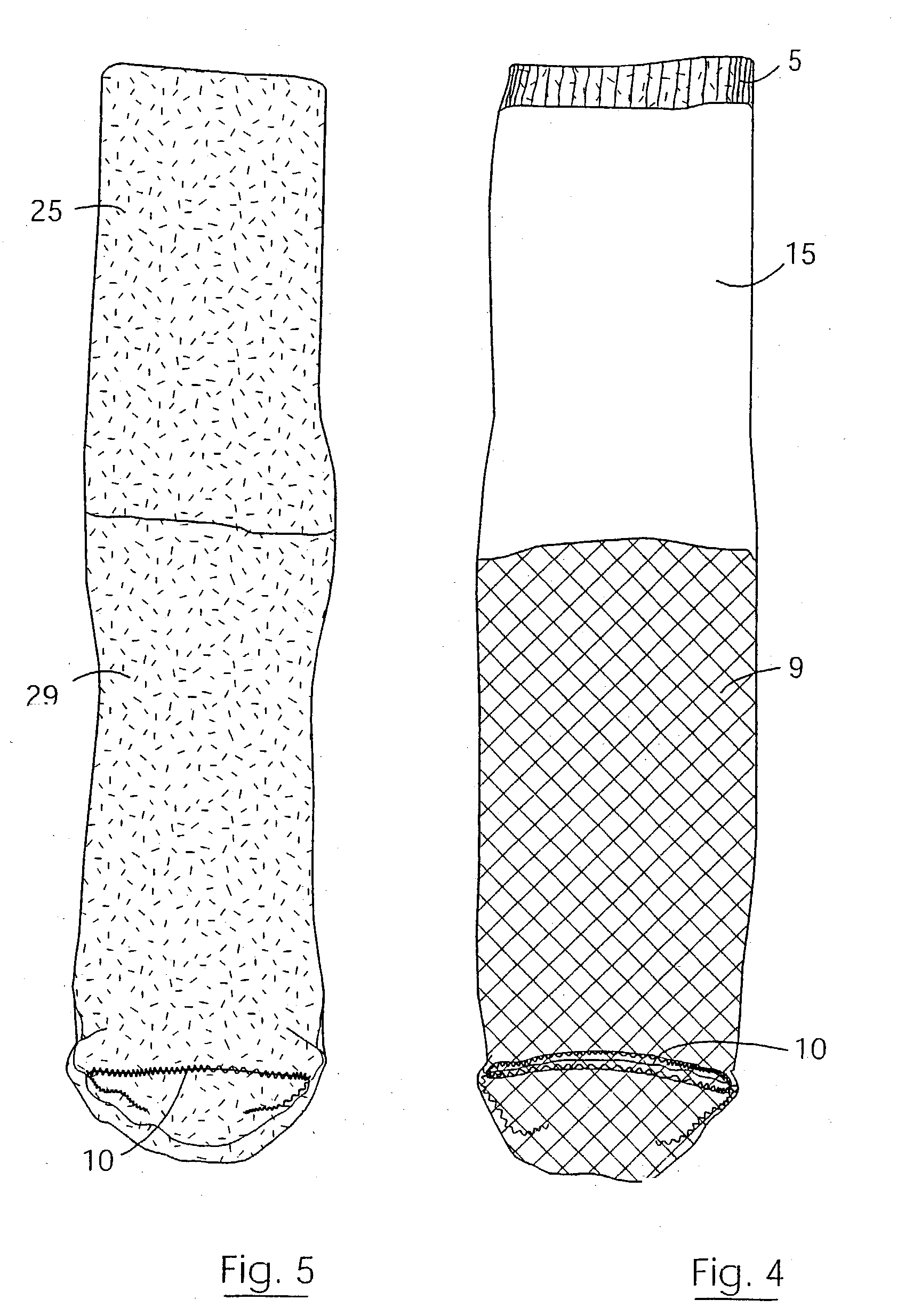

[0235] A double layer sock is produced on a Sangiacomo circular knitting machine with a Lintoe attachment as follows.

[0236] The dial is prepared by attaching an Elastane yarn (which may be coated with Teflon). The connecting yarn is led from the cylinder needles to dial elements.

[0237] Silver coated Nylon fiber is then introduced by a yarn carrier change.

[0238] The cylinder is reciprocated to produce an internal toe pouch using the silver coated Nylon fiber.

[0239] The internal foot of the sock is then knit by the cylinder.

[0240] The internal heel is then knit from the silver coated Nylon fiber by reciprocating the cylinder.

[0241] The inner ankle (high heel) is then knitted continuously using the silver coated Nylon fiber.

[0242] The yarn carrier is then changed so that the cylinder is fed with Tactel Nylon fiber which is used to knit the leg part of the inner sock.

[0243] When the leg part has been knit there is another yarn carrier change to introduce a mixture of cotton, Nylon and e...

example 3

[0271] A double layer sock is produced on a Sangiacomo circular knitting machine with a Lintoe attachment as follows.

[0272] The dial is prepared by attaching an Elastane yarn (which may be coated with Teflon). The connecting yarn is led from the cylinder needles to dial elements.

[0273] Teflon fibre or yarn, silver coated fibre or yarn and Lycra fibre or yarn are then introduced by yarn carrier changes. The cylinder is reciprocated to produce an internal toe pouch using these 3 fibres.

[0274] The internal foot of the sock is then knit by the cylinder using these 3 fibres.

[0275] The internal heel is then knit from the Teflon fibre or yarn, the silver coated fibre or yarn and the Lycra fibre or yarn by reciprocating the cylinder.

[0276] The inner ankle (high heel) is then knitted continuously using the same three fibres.

[0277] The yarn carrier is then changed so that the cylinder is fed with Tactel Nylon fibre which is used to knit the leg part of the inner sock.

[0278] When the leg part ...

example 4

[0309] A double layer sock is produced on a Sangiacomo circular knitting machine with a Lintoe attachment as follows.

[0310] The dial is prepared by attaching an Elastane yarn (which may be coated with PTFE). The connecting yarn is led from the cylinder needles to dial elements.

[0311] A composite yarn comprised of a blend of PTFE fibre and another conventional fibre (hereafter referred to as the PTFE blend) (an example is Dupont's Teflon SY yarn, comprised of 50% PTFE and 50% dacron fibre) is then introduced by a yarn carrier change. Dacron is an engineered polyester.

[0312] The cylinder is reciprocated to produce an internal toe pouch using the PTFE blended yarn.

[0313] The internal foot of the sock is then knit by the cylinder.

[0314] The internal heel is then knit from the PTFE blended yarn by reciprocating the cylinder.

[0315] The inner ankle (high heel) is then knitted continuously using the PTFE blended yarn.

[0316] The yarn carrier is then changed so that the cylinder is fed with T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of friction | aaaaa | aaaaa |

| terry structure | aaaaa | aaaaa |

| hydrophilic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com