Gravimetric moisture-determination instrument with an air duct for cooling

a technology of air duct and gravity, applied in the direction of weighing by absorbing components, weighing by removing components, and material thermal analysis, etc., can solve the problems of dust particles from the ambient air clogging up the filter pad, weight loss measured by balance, and user neglecting to do, so as to improve the design of the air duct and simple routine procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

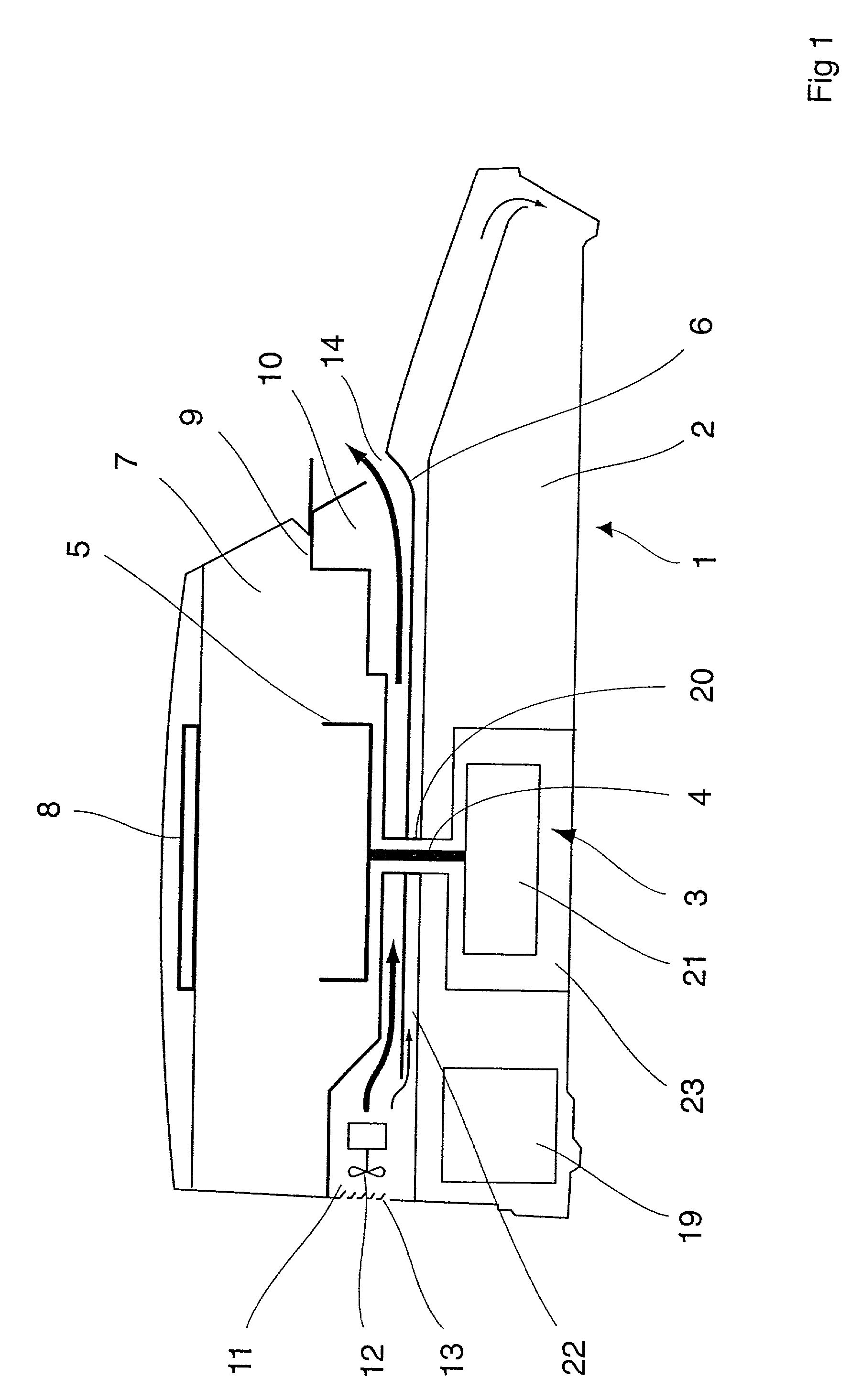

[0016] The moisture-determination instrument 1 of FIG. 1 has an instrument housing 2 containing a balance 3. The balance has a load-receiving connection 4 protruding through an opening in the housing 2 and supporting a removable sample tray carrier 5. A plate 6 covers the top of the instrument housing 2 except for an opening in the rear portion of the housing. The pass-through collar 20 for the load-receiving connection 4 through the plate 6 is sealed so that air and dust from the air duct cannot penetrate the areas of the weighing cell 21 and the sample tray carrier 5. The weighing cell 21 has its own enclosed compartment 23, which is sealed against dust and air from the outside. Integrated in the tilt-up cover 7 is a radiant heater 8 to heat-dry the samples whose moisture content is to be determined. When the tilt-up cover 7 is closed, its side walls adjoin the plate 6 substantially over its full length and thereby close off the interior space of the moisture-determination instrum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight loss | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com