Welding joint steel plated with excellent low-temperature flexibility

A steel plate, ferrite technology, applied in the direction of welding medium, welding equipment, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] For steel billets containing C: 0.08%, Si: 0.15%, Mn: 1.50%, P: 0.009%, S: 0.002%, Al: 0.038%, Ti: 0.014%, N: 0.0046% (steel symbol: A; The remainder is Fe and unavoidable impurities), and rolled to a predetermined thickness under various conditions shown in Table 1 below.

[0059] The evaluation results of the obtained steel sheets are shown in Table 1 below.

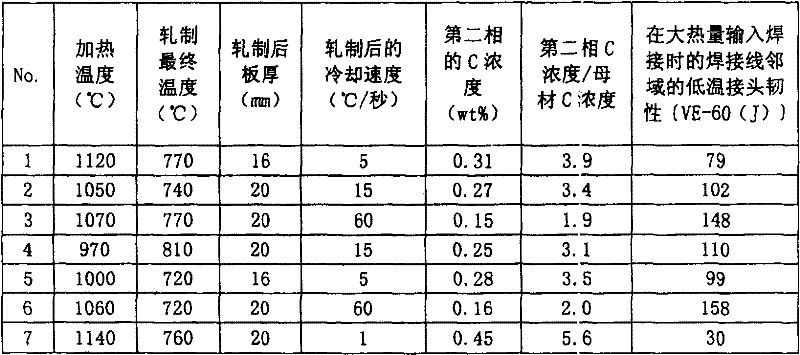

[0060] Table 1

[0061]

[0062] It can be seen from Table 1 that in the case of No.7, because the concentration of C in the second phase is too high, the low-temperature joint toughness near the welding line is poor when welding with high heat input. On the other hand, in the examples of No. 1 to 6, since the C concentration in the second phase is appropriate, the low-temperature joint toughness in the vicinity of the welding line at the time of high heat input welding is excellent.

Embodiment 2

[0064] A steel material (steel type A) having the same composition as in Example 1 and a steel material having a composition shown in Table 2 below was melted, and rolled to a predetermined thickness under various conditions shown in Table 3 below.

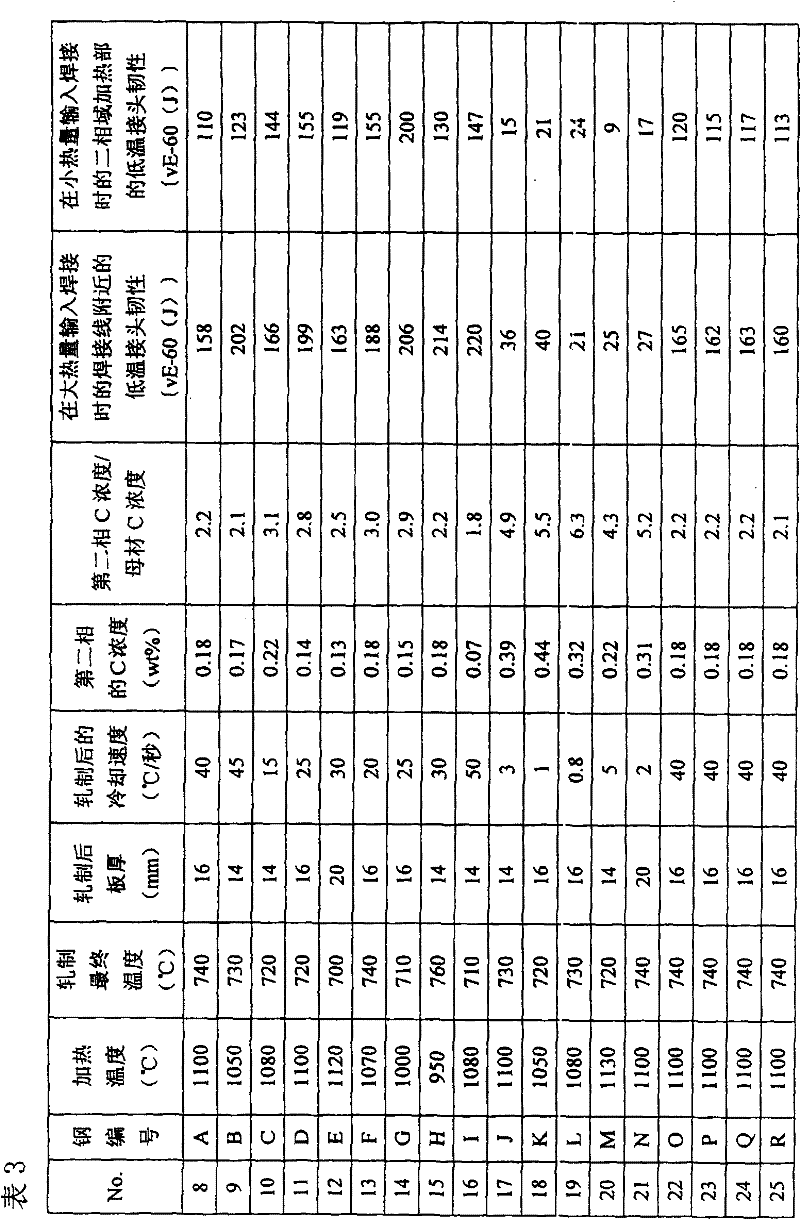

[0065] The evaluation results of the obtained steel sheets are shown in Table 3 below.

[0066]

[0067]

[0068] It can be seen from Table 2 and Table 3 that in the examples of No.17-21, because the concentration of C in the second phase is too high, the low-temperature joint toughness near the welding line during high-heat input welding is poor, and the low-heat The low-temperature toughness of the heating part in the two-phase region at the time of input welding is also poor. On the other hand, in the examples of Nos.8 to 16, since the concentration of C in the second phase is appropriate, the low-temperature toughness of the heating portion in the two-phase region during welding with high heat input and the vicinity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com