A nano micro-capsule emulsion of snake oil and method for preparing same

A technology of nano-microcapsules and snake oil, applied in the field of snake oil nano-microcapsule emulsion and its preparation, to achieve the effects of increasing moisture retention, good water solubility, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

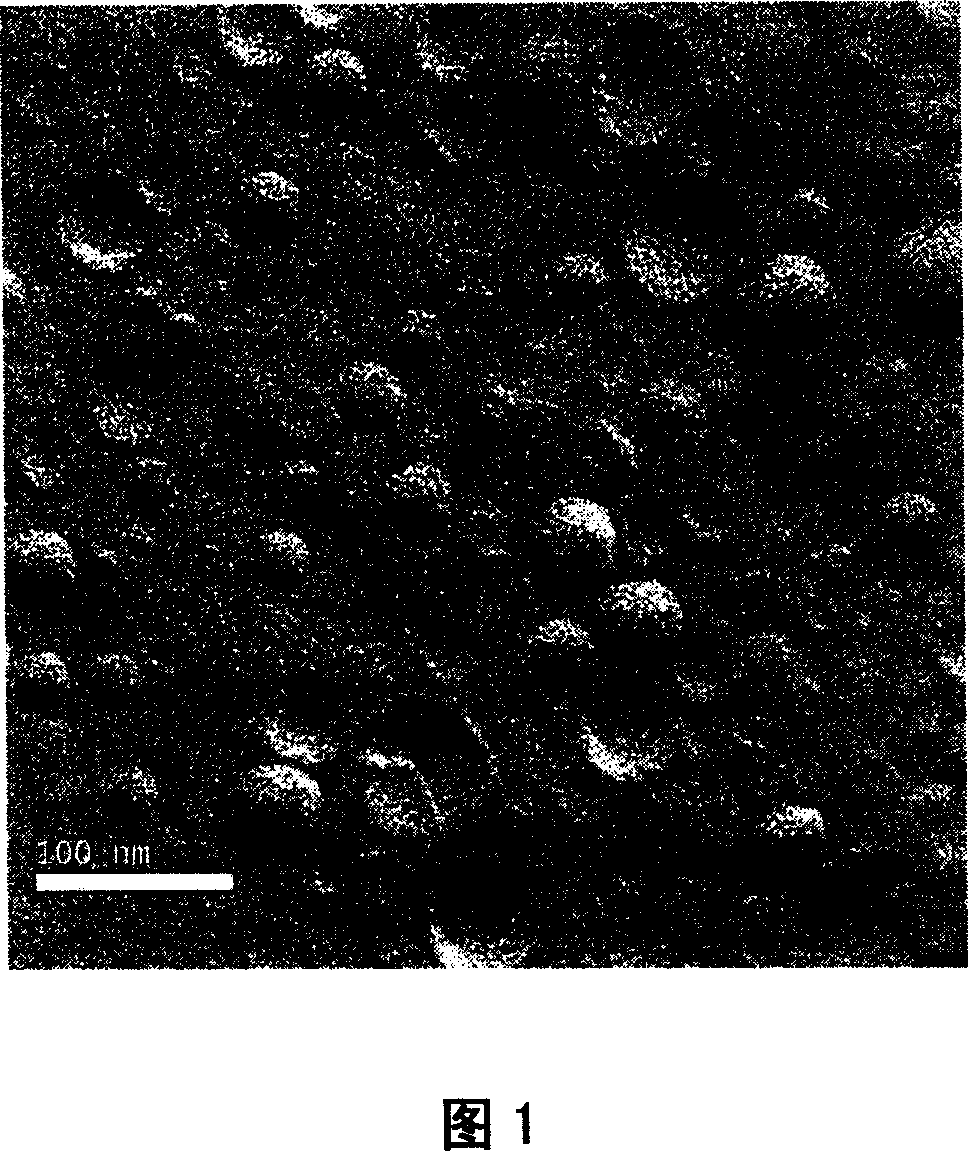

Image

Examples

preparation example Construction

[0037] The preparation method of snake oil nano microcapsule emulsion of the present invention can be carried out as follows:

[0038] 1) Prepare a homogeneous mixed liquid A by mass percentage of 1-20% snake oil, 1-20% phospholipid and 1-20% surfactant at a temperature of 20°C-70°C and stirring conditions;

[0039] 2) Mix the above-mentioned mixed solution A with a dispersion medium with a mass percentage of 50-95% at a temperature of 20°C to 70°C under stirring conditions to prepare a homogeneous mixed solution B;

[0040] 3) Process the mixed solution B obtained in step 2) through a high-pressure homogenizer, the high-pressure homogenization pressure is 200bar to 1500bar, and the number of cycles is 2 to 20 times to obtain a transparent or translucent particle size less than 100nm Nano snake oil microcapsule emulsion.

[0041] In the above preparation method, the present invention can add 0.1-4% by mass percentage of fat-soluble antioxidant to the homogeneous mixture A, an...

Embodiment 1

[0044] Example 1 Weigh 2% phospholipids at 45°C and 50min -1 Stir with 1% black snake and Agkistrodon snake oil, 1% polyoxyethylene hydrogenated castor oil, 1% polyethylene glycol caprylic acid / capric glyceride and 0.2% vitamin E under the condition of rotating speed to form a uniform mixture, and then in 45℃ and 1800min -1 Mix the above-mentioned mixed solution with 94.8% aqueous solution containing 75% sorbitol under the condition of rotating speed, and continue to stir until a uniform emulsion is formed, and finally the emulsion is circulated through a high-pressure homogenizer for 18 times under the pressure of 200bar to obtain granules Transparent snake oil nano-microcapsule emulsion with diameter less than 100nm.

Embodiment 2

[0045] Example 2 Weigh 9% phospholipids at 40°C and 400min -1Stir with 9% Piper viper oil and 9% polyoxyethylene hydrogenated castor oil under rotating speed conditions to form a homogeneous mixture, and then heat at 25°C and 800min -1 Mix the above mixed solution with 3% vitamin C and 70% aqueous solution containing 75% glycerol under the condition of rotating speed, and continue to stir until a uniform emulsion is formed, and finally the emulsion is circulated through a high-pressure homogenizer for 3 times under the condition of 1500bar pressure , promptly obtain the transparent snake oil nano-microcapsule emulsion whose particle diameter is less than 100nm nanometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com