Detecting tools for combustion turbine transitory section renovation technique and renovation technique thereof

A technology for gas turbines and transition sections, applied to mechanical measuring devices, turbines, measuring devices, etc., can solve problems affecting normal production, heavy economic burden on users, difficulty in meeting quality standards, etc., and achieve great practical value, strong standardization, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

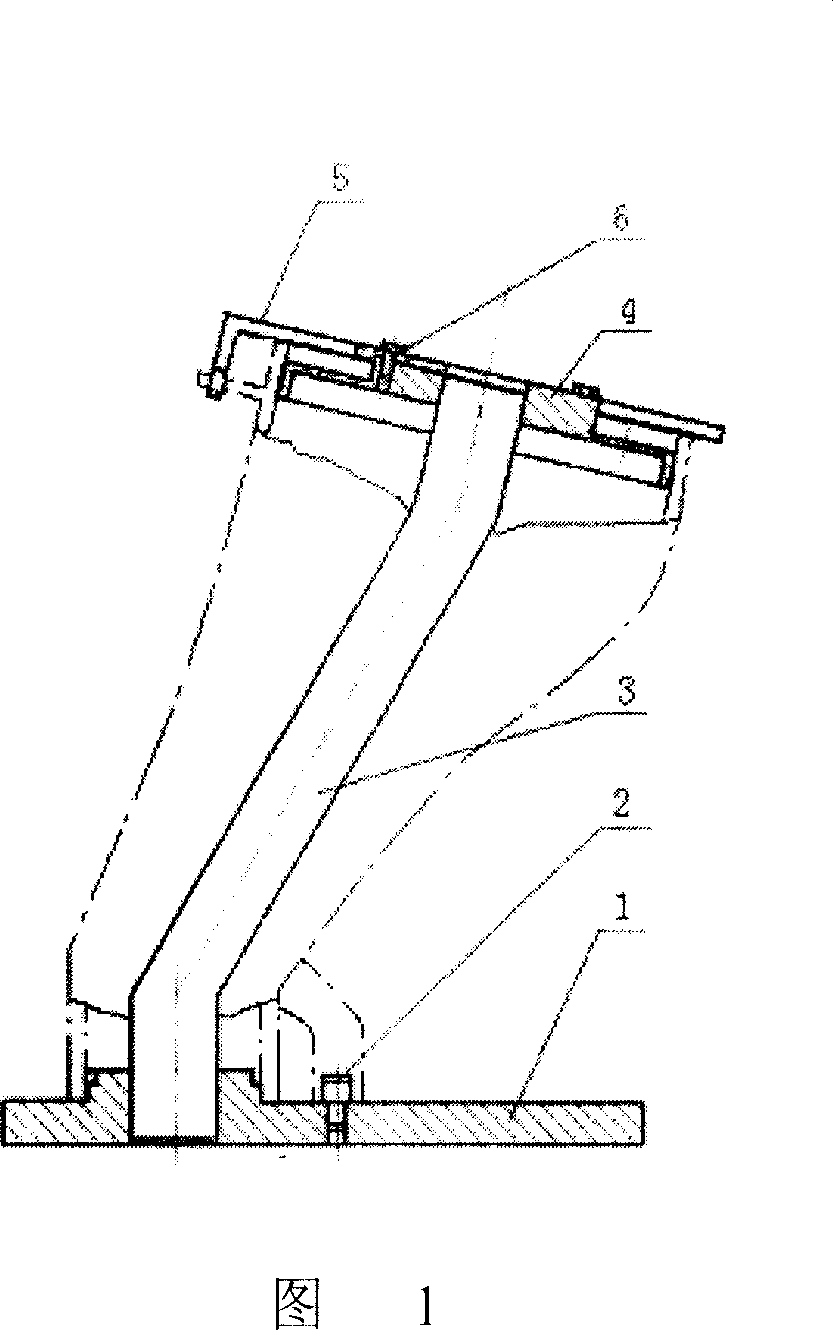

Image

Examples

Embodiment 1

[0019] The process steps are as follows:

[0020] 1. Sand blowing. Clean dirt from the interior and exterior surfaces of the restoration.

[0021] 2. Non-destructive testing. Detect defects in the transition section, including cracks, corrosion, etc., and make detailed inspection records for deformation and wear failures.

[0022] 3. Make a special calibration model. For the transitional section that is deformed, measure other transitional sections that have the same shape as the deformed part, and make a shape-calibration template based on the measured position.

[0023] 4. Material analysis, confirmation of material, and selection of special powder for laser cladding (material properties after melting and casting are not lower than the performance requirements of the base material).

[0024] 5. Remove the fatigue layer from the burnt parts and cracks, and the cracks should be cleaned up.

[0025] 6. Laser casting. Laser welding is performed on cracks and ablation parts...

Embodiment 2

[0040] Example 2 Repair of a worn transition section around a sealing groove and a round hole

[0041] The process steps are as follows:

[0042] 1. Sand blowing. Clean dirt from the interior and exterior surfaces of the restoration.

[0043] 2. Non-destructive testing. Detect whether there are other defects such as cracks and corrosion in the transition section, and carry out detailed inspection records for failures such as deformation and wear.

[0044] 3. Make a special calibration model. For the transitional section that is deformed, measure other transitional sections that have the same shape as the deformed part, and make a shape-calibration template based on the measured position.

[0045] 4. Material analysis, confirmation of material, and selection of special powder for laser melting (the performance of the material after melting and casting is not lower than the performance requirements of the base material).

[0046] 5. Measure and record the width of the seali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com