Penetrating support structure and its production

A support structure and penetrating technology, applied in the field of plate-shaped heat conduction elements, can solve problems such as affecting heat dissipation efficiency, blocking steam flow, and steam cannot circulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

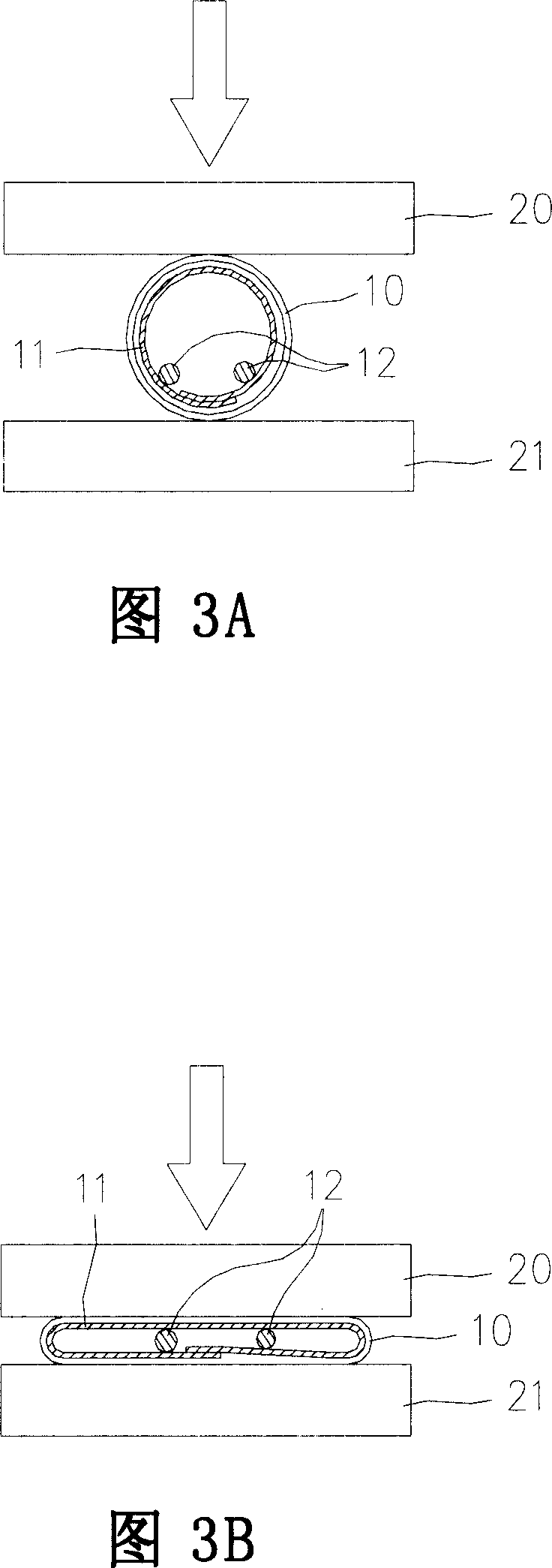

[0072] The technical means and functions adopted to achieve the object of the present invention will be described below with reference to the accompanying drawings, and the implementations listed in the following accompanying drawings are only exemplary, and the technical means of the application are not limited to the accompanying drawings.

[0073] The penetrable support structure provided by the present invention is suitable for liquid-vapor two-phase thin vapor chambers or plate-shaped heat pipes, and can be applied to heat dissipation, soaking or heat transfer of heating elements in general electronics, optoelectronics, and communication products. Or computer chips, CPUs, monitors, LEDs, LCDs, light-emitting diodes, mobile phones, PDAs, video games, industrial computers, servers, etc., or general household appliances, refrigeration and air conditioning, automobiles, factory machinery, power plants, solar panels, chemical reactors, etc. heat dissipation, heat removal, heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com