Antenna circuit, ic inlet, and ic tag

一种天线电路、插入物的技术,应用在非接触IC标签领域,能够解决制造工序增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0089] (Manufacture of antenna circuit)

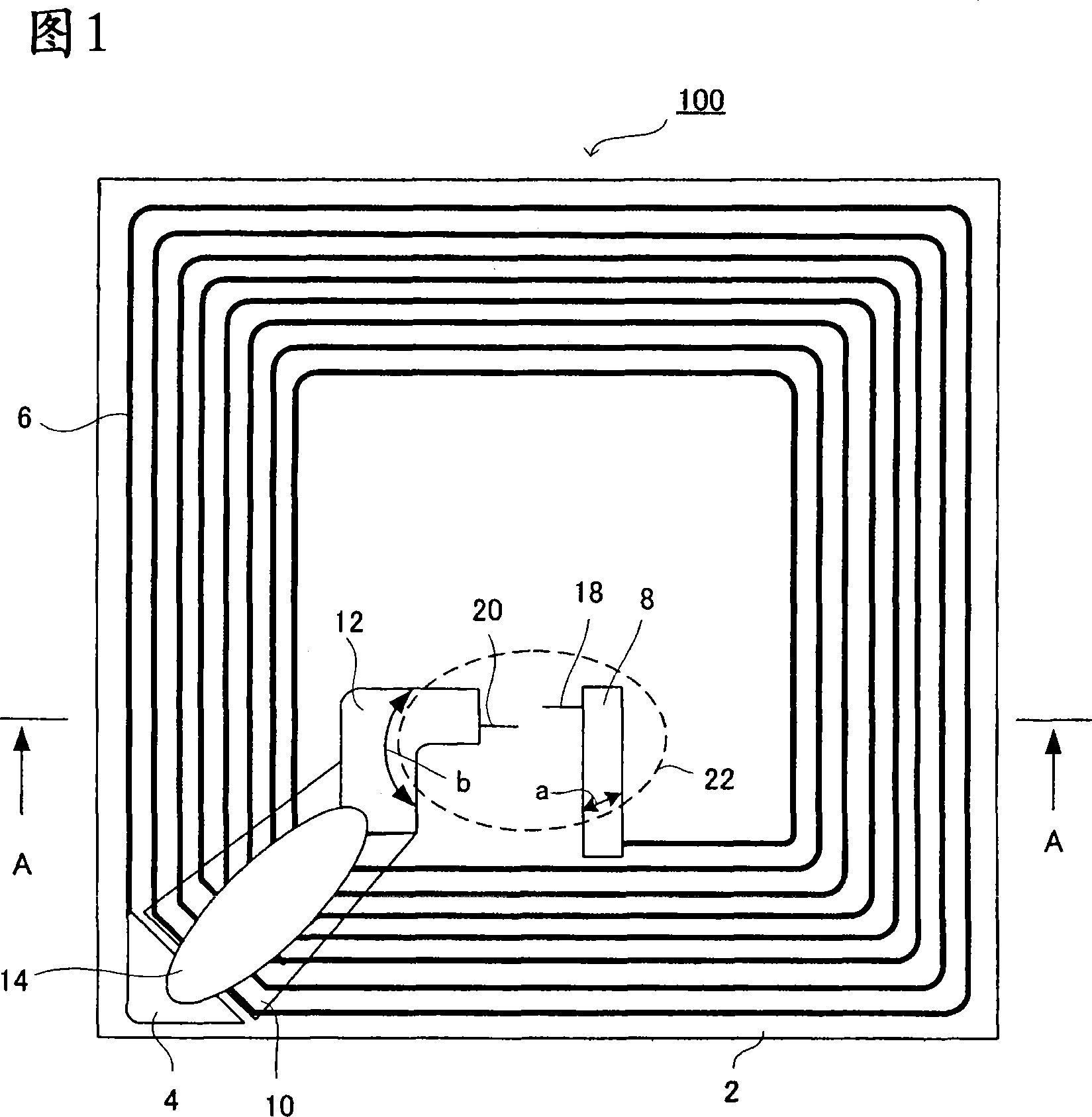

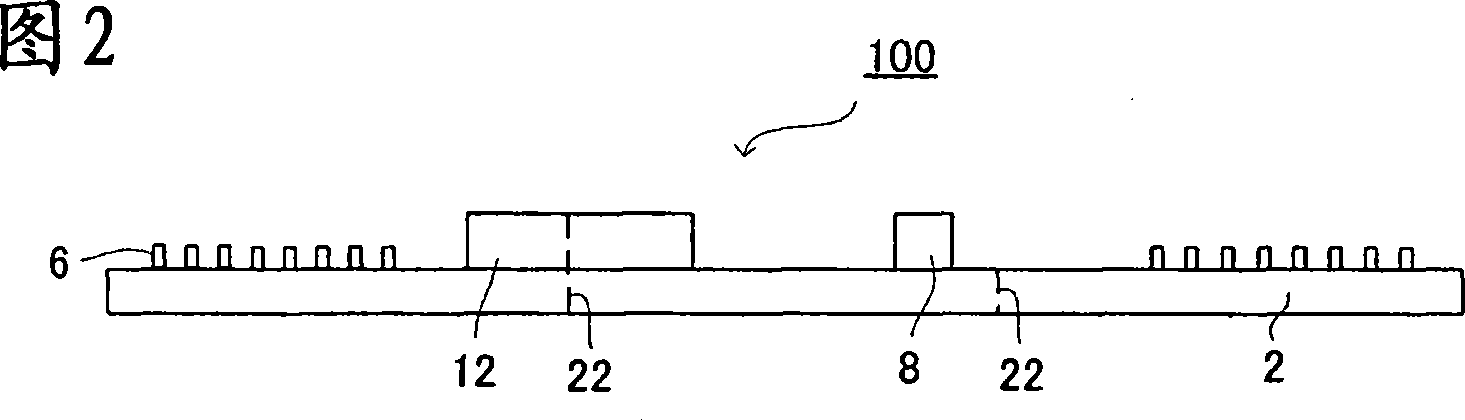

[0090] The antenna circuits 100 shown in FIGS. 1 and 2 are manufactured in groups of 20 by the method described below.

[0091] First, a resist pattern was printed by a screen printing method on the brand name Nika Flux (Cu / PET = 35 μm / 50 μm manufactured by Nikon Kogyo Co., Ltd.) in which copper foil and polyethylene terephthalate film (PET) were bonded. The resist pattern is made, and the planar coil circuit portion 6, the counter electrodes 8, 12, and the lead portions 18, 20 are used as one constituent unit, and 20 constituent units are arranged vertically and horizontally. The nicaflex printed with a resist pattern is etched to remove unnecessary copper foil portions, and the planar coil circuit 6, the counter electrodes 8, 12, and the lead portions 18, 20 are formed.

[0092] Then, a lead electrode 4 was formed with silver paste (DW250L-1 manufactured by Toyobo Co., Ltd.) on one end of the planar coil circuit portion 6 described above...

manufacture example 2

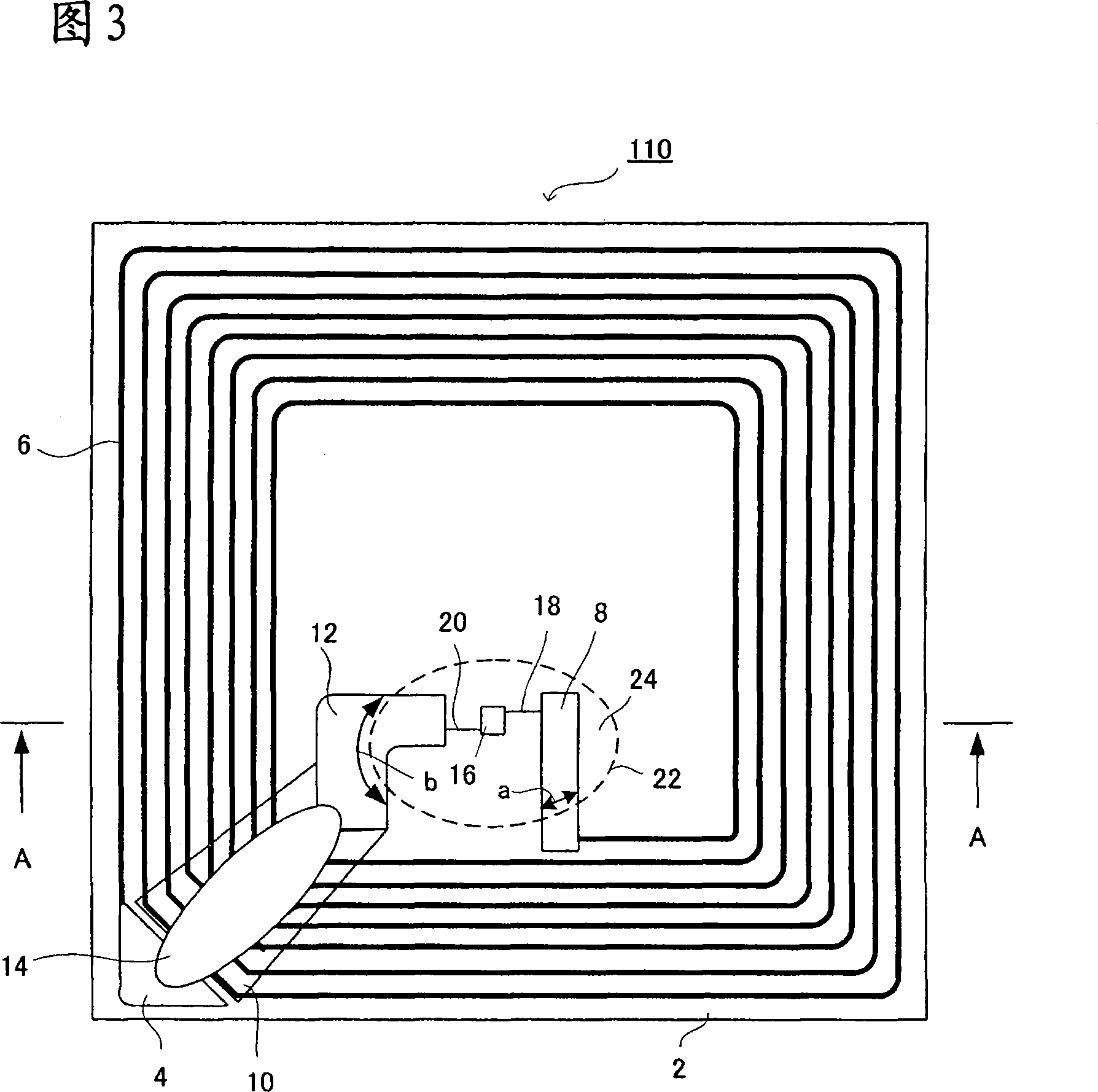

[0097] (Manufacturing of IC Insert)

[0098] An RFID-IC chip (I Code manufactured by Philips Co., Ltd.) was mounted on the antenna circuit manufactured as described above, and 20 IC inserts 110 having the configurations shown in FIGS. 3 and 4 were manufactured.

[0099] In actual installation, a flip chip mounter (FB30T-M manufactured by Kyushu Matsushita) is used. Furthermore, as an adhesive material, an anisotropic conductive adhesive (TAP0402E manufactured by Kyocera Co., Ltd.) was used, and thermocompression bonding was performed under the conditions of 220°C and 200 gf (1.96N) for 7 seconds.

Embodiment 1

[0101] (Manufacture of IC tags)

[0102] Using the above-mentioned IC insert, acrylic adhesive (manufactured by Lintec Co., Ltd., trade name, PA-T1) was coated with a thickness of 25 μm on a thin translucent paper coated with silicone resin as a release material ( The peel-off processing surface of Rintec Co., Ltd., trade name, 8KX) was bonded to the surface circuit forming surface of the IC insert. In this way, 20 IC tags having the same configuration as the IC tag 120 shown in FIG. 6 were manufactured.

[0103] The operation confirmation of the 20 manufactured IC tags was based on a Read / Write test using the I Code evaluation tool SLEV400 manufactured by Fisher.

[0104] Using SLEV400, after confirming that the IC tag is operating normally, stick the IC tag on the polypropylene resin board. After being removed from the board after 24 hours, as shown in Figure 7, the IC chip area remained on the polypropylene resin board, and the circuit was destroyed. All 20 damages were confirm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com